The engine has an overhead camshaft. Camshaft drive by toothed belt. The cylinder block is cast iron, the cylinder head is aluminum.

Compared to the diesel engines that were previously installed, it has several design changes:

- cylinder head, valve seats, valves and combustion chambers are made of materials that can withstand higher temperatures;

- special nozzles (nozzles) spray oil on the bottom of the pistons, cooling them;

- redesigned pistons;

- front end of the crankshaft modified;

- the oil cooler is located between the oil filter and the filter flange;

- in connection with the installation of a turbocharger, the exhaust system and intake system were modified.

Attention! All diesel engines are very sensitive to dirt, therefore, when carrying out any work on the engine, make sure that dirt or other foreign bodies do not get into the openings of the pipelines and their connections. It is best to immediately seal all fuel lines, hoses and other openings with duct tape. Disassembly of the engine is described in detail in subsection. 17.3-17.10. Thus, we can consider the work that can be carried out either on an installed engine or on a removed one, without describing any operation for disassembling the engine twice. If a complete disassembly of the engine is carried out, then simply combine the individual operations with each other in the sequence indicated. When disassembling, mark the location of all removable parts and parts in order to reassemble them in their original position in case they are to be reused. This is especially important for pistons, valves, caps and bearing shells. Fold the parts in such a way that they are not mixed up.

Attention! Do not mark bearings and seals with surface scratches or marks. Many of the parts are made of light alloy and must therefore be handled with care. If a hammer must be used to remove a part, it can only be a rubber, plastic or leather-covered hammer.

If possible, install the motor on an appropriate mounting stand. When disassembling the engine, proceed in the following sequence:

- remove the thrust bearing bracket of the drive shaft, as well as the turbocharger;

- drain the engine oil.

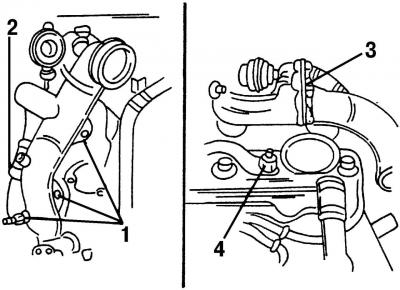

Pic. 374. When carrying out any disassembly work, disconnect: 1 - intake pipe mounting bolts; 2 - air hose from the turbocharger; 3 - charge air hose from the intake system; 4 - crankcase ventilation hose

Remove the following details from the engine, being guided by fig. 374:

- unscrew bolts 1 and disconnect the inlet pipe from the turbocharger;

- disconnect the air hose 2 from the turbocharger and charge air cooler;

- Disconnect the charge air hose from the intake system 3;

- Disconnect the crankcase ventilation hose 4 from the oil filter.

Disconnect the coolant line and remove the coolant hose from the holder and oil cooler.

Remove the hose clamp from the flywheel side and disconnect the coolant line.

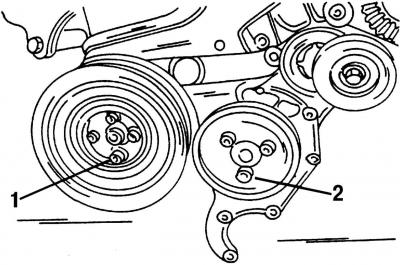

Pic. 375. Remove the crankshaft vibration damper 1 and the power steering pump pulley 2. The power steering pump pulley can be fixed in a fixed position with a hexagon

Remove the crankshaft pulley located at the front of the engine (4 bolts) and power steering pump pulley (pic. 375).

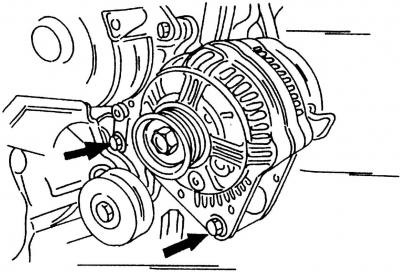

Pic. 376. Mounting the generator. V-belt tensioner visible from below

Remove generator (pic. 376).

Loosen the four bolts securing the engine mount clamp and remove it.

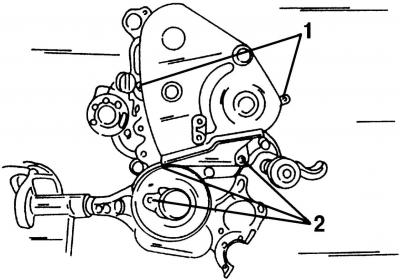

Pic. 377. Fastening the safety covers of the V-ribbed belt: 1 - top cover; 2 - bottom cover

Remove the upper poly V-belt cover. It is fastened with spring clamps 1 (pic. 377). Open the bottom cover. It is attached with 3 bolts 2.

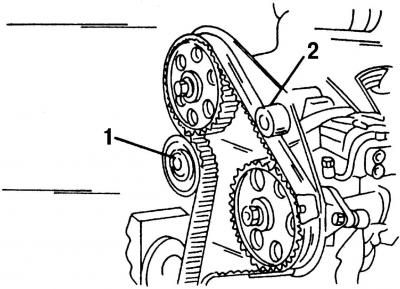

Pic. 378. Removing the V-ribbed belt: 1 - tension roller of the toothed drive belt; 2 - guide roller of the toothed drive belt

Remove poly V-belt. If you plan to reinstall the old belt, mark the direction of travel of the V-ribbed belt by making a colored mark on its surface. Turn away a nut and wring out a tension roller 1 (pic. 378) to the side. Remove the guide roller 2. Remove the toothed belt. Remove the belt tensioner.

Remove the cylinder head cover. Disconnect the crankcase ventilation hose from the lower connection and leave it on the cylinder head cover. Remove the protective caps located above the nuts securing the cylinder head cover, unscrew the nuts and remove the cover.

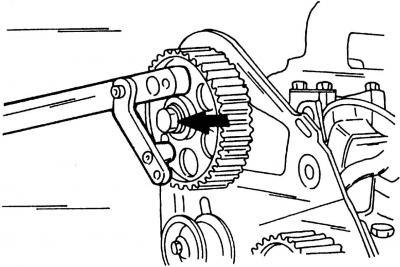

Pic. 379. Method of fixing the gear wheel of the camshaft

Fix the camshaft pulley in a fixed position, remove it. The stop intended for this is shown in Fig. 379. You cannot use a puller for this operation; you can insert a mandrel through the hole in the metal wall located behind the wheel and knock down the pulley in a circle.

Remove the injection pump gear. It should be removed using a special three-prong puller, the teeth of which must be inserted into the holes on the pump gear. First unscrew the gear nut. To fix the gear in a stationary state, insert the mandrel into the hole on the pump gear and hold it, resting the mandrel against the cylinder block.

Turn away two bolts on a head of cylinders and a bolt on TNVD and remove internal protection of a V-ribbed belt.

Remove the dipstick to measure the engine oil level.

Disconnect the wire end of the fuel shutoff valve and from the injection control solenoid valve.

Unscrew the high pressure fuel lines from the injectors and injection pump. They are fastened with captive nuts.

Remove the injection pump. To do this, unscrew the two nuts on one side and the bolt with the nut on the other side.

After that, disconnect the various wires and hoses. They are shown in Figure 380:

- disconnect the plug of oil pressure switch 1;

- disconnect the plug connector of the temperature sensor 2;

- remove from the bracket the plug connector of the crankshaft position sensor 3;

- disconnect the plug of the needle lift sensor 4 from the holder;

- Disconnect the coolant hose 5 from the distribution chamber of the cylinder head.

Unscrew the glow plug electrical bus and disconnect the oil drain hoses.

Loosen the injector fasteners and remove the injectors from the cylinder head.

Unscrew the glow plugs.

Disconnect the connector from the coolant temperature sensor.

Loosen the hollow bolt, O-ring, flare nut on the turbocharger located near the turbocharger and unscrew the connection. Disconnect the auxiliary heating connector, remove the wiring harness on the engine and unscrew the connecting pipe for exhaust gas recirculation (4 bolts).

Remove the exhaust pipe and turbocharger. Loosen the oil pipe ring hollow bolt first, then unscrew the exhaust pipe heat shield (2 bolts), and then unscrew the 8 bolts securing the exhaust pipe.

Remove the 6 exhaust manifold mounting bolts and remove it.

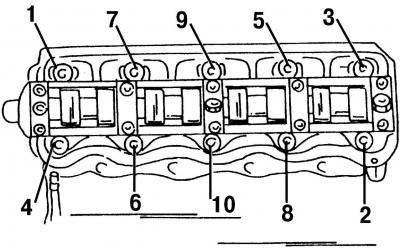

Pic. 382. The order of unscrewing the bolts of the cylinder head. When installing the cylinder head, tighten the bolts in reverse order

Loosen the cylinder head bolts evenly in reverse order of tightening the bolts (pic. 382) and take them out. To loosen the bolts, a special hex wrench is required, without which it is possible to damage the inside of the hex head of the bolts, so that they can no longer be unscrewed. Remove the cylinder head gasket.

Attention! Bolts are not suitable for reuse and must be replaced with new ones.

Remove the accessory mounting bracket and oil filter.

Unscrew the injection pump mounting bracket (3 bolts) and remove the oil cooler (one nut in the center).

Remove the three bolts in the oil filter base and remove the oil filter base. Remove the vacuum pump tension plate and remove the pump.

Remove the components installed on the left side of the engine: crankcase ventilation connection (2 bolts), crankshaft position sensor (1 bolt, 1 spring clip) and a dipstick for measuring the oil level in the engine.

Fix the crankshaft in a fixed position by inserting a screwdriver into the ring gear. Loosen the 6 clutch mounting bolts evenly and crosswise so that they can be removed. Then completely remove the clutch.

Remove the crankshaft and countershaft gears from the front side of the engine. Lock the crankshaft and intermediate shaft in a fixed position.

Lock the flywheel in a fixed position and unscrew the 6 bolts of its fastening.

Remove the motor intermediate plate.

Turn the engine over and unscrew the oil pan (20 bolts). Remove the gasket.

Unscrew the oil pump located at the bottom of the crankcase and remove it.

Remove the six bolts and remove the O-ring rear flange. Remove the gasket.

Attention! The flange is unsuitable for reuse and must be replaced with a new one.

Remove the crankshaft oil seal from the front of the engine. Remove the gasket. Knock out the seal.

Turn away a flange of an intermediate shaft and wring out a flange. Under the flange is an o-ring. Remove the shaft from the engine.

Rotate the crankshaft so that the two connecting rods are at bottom dead center. Mark the connecting rod bearing caps with cylinder numbers (color) and unscrew the bearing caps one by one. Remove the connecting rods one by one with the pistons upwards from the cylinder bore. Please note that the bearing shells and bearing caps are immediately attached to the appropriate connecting rods.

Remove the crankshaft. Bearing caps in this case are marked with numbers (No. 1 - pulley side, No. 5 - flywheel side). See subsection 17.9.

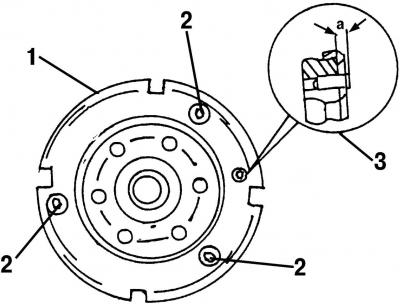

Pic. 383. Flywheel: 1 - gear rim; 2 - bolts for fastening the gear rim; 3 - set screw (should protrude a distance a)

Unscrew the gear rim used to determine the speed of the crankshaft from the toe of the crankshaft. On fig. 383 shows the method of its fastening.

Remove the oil nozzles from the bottom of the crankcase (unscrew the bolts).

Visitor comments