Disconnect all details located on a head of the block of cylinders. Unscrew the four nozzles from the head and place them in such a way that they are well protected from damage due to hitting each other. Remove glow plugs.

Clamp the cylinder head, together with the clamp screwed to the exhaust manifold set screw, in a vise.

Remove the camshaft (see 17.8.1).

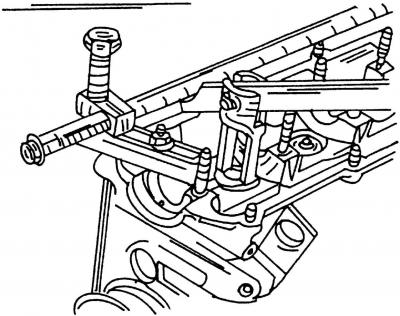

Pic. 394. Compressing the valve spring with a special puller

A standard valve removal and installation tool and how to install it is shown in fig. 394. The heel of the tool must be on the inside of the valve spring seat, otherwise the spring cannot be compressed. Press the lever of the tool and compress the spring so that the valve stem halves can be removed. To remove the valves, you can also use a piece of pipe that is put on the upper spring plate. Under the valve plate on the other side, you need to put something to fix it. Tap the pipe briefly with a hammer until the valve stem halves come out. They will stay inside the pipe. But do not tear off the pipe from the spring plate, so as not to lose half of the valve stem.

The valve spring caps can also be compressed with two screwdrivers. In this case, place a rag in the combustion chamber of the cylinder head so that the valve does not fall down.

Remove the valve stem and spring halves, and then remove the valve.

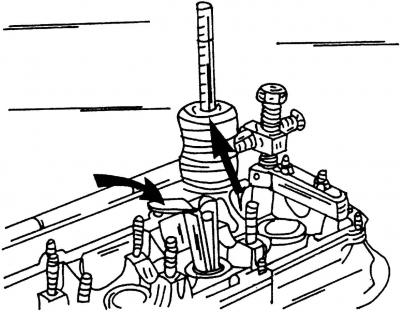

Pic. 395. Removal of oil caps

Remove the oil seals. To remove the oil seals, it is best to use a special tool (3047A), as shown in Fig. 395. The tool is a kind of plastic mallet with an adapter, which is substituted under the valve stem seals. The oil seals can also be removed with an angled screwdriver. However, in this case, special care must be taken not to damage the surface of the holes of the poppet pushers. Always install new oil seals.

Remove the lower plates of the Belleville spring from the holes.

Visitor comments