- parts must be clean;

- always lubricate any rotating or sliding parts. This should be done before assembly (not after the parts are already installed), then the oil will get to all the necessary places. It is especially important to generously lubricate the pistons, piston rings and cylinder walls with engine oil before assembly;

- thoroughly clean all parts of the cylinder block if the engine has been completely disassembled. When partially disassembling, make sure that foreign bodies do not get into the disassembled engine or into its cavity. Plug all openings with clean rags to avoid this;

- blow out the oil passages with compressed air. If you do not have such an opportunity, then clean the oil channels and holes with a wooden stick, but in no case do this with metal objects.

The table with data for adjustment and control shows the wear limits of most moving parts. If you have doubts about any part, or the wear limit will soon be reached, then it is better to replace such a part in order to avoid re-disassembly of the engine.

The following describes the assembly of the engine after it has been completely disassembled. In doing so, we assume that all engine parts have been repaired or replaced in accordance with the instructions given in the following sections. In addition, we assume that individual structural groups, such as the cylinder head, are already assembled.

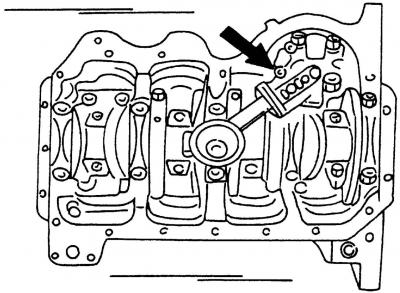

Install the oil jets to the cylinder block. Tighten the injector mounting bolts to 10 Nm.

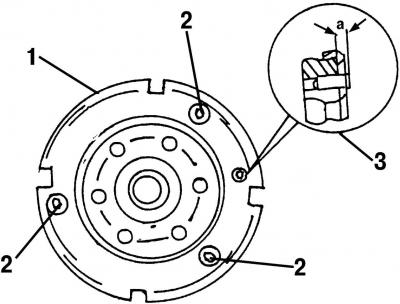

Pic. 383. Flywheel: 1 - gear rim; 2 - bolts for fastening the gear rim; 3 - set screw (should protrude a distance a)

Screw the gear rim of the crankshaft speed sensor. Bolts should always be replaced with new ones. Dowel pin inserted into crankshaft (pic. 383), this pin must protrude a certain amount from the surface of the crankshaft (2.5-3.0mm). Therefore, before screwing the gear rim (torque 10 Nm), measure the distance that the dowel pin protrudes.

Lubricate all running surfaces of the crankshaft bearings with engine oil and place the crankshaft on the bearing shells. Carefully place the crankshaft inside the bearings and install the shims to the left and right of the middle bearing. The oil grooves of the shims must be against the bearing surface of the crankshaft.

Install in the cylinder block in accordance with the marks of the main bearing cap (bearing shells must be inserted and well lubricated) and beat them with a plastic or rubber mallet.

Screw in the bolts of the main bearing caps and tighten them evenly from the middle outwards to a torque of 65 Nm. From the end position, turn each bolt, again from the center outward, another 90° (quarter turn).

Attention! Use only new bolts.

Check the crankshaft end play as described in clause 17.9.1.

Install pistons and connecting rods (see 17.5.5).

Press a new oil seal from the outside into the intermediate shaft flange.

Lubricate the intermediate shaft bearing journals and insert the intermediate shaft into the crankcase. Install a new O-ring into the shaft flange and install the flange. Tighten both bolts to 25 Nm.

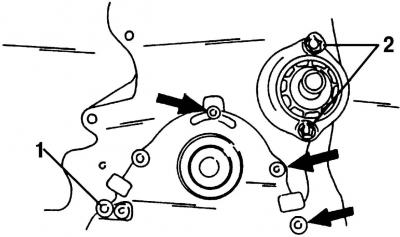

Pic. 384. The bolts of the stuffing box 1 of the crankshaft and the flange 2 of the intermediate shaft must be tightened to a torque of 25 Nm

Knock the oil seal out of the front oil seal housing. Insert the housing without oil seal into the cylinder block. Tighten 4 bolts to 25 Nm. On fig. 384 shows the method of its fastening.

Install a new front oil seal as described in paragraph 17.9.3.

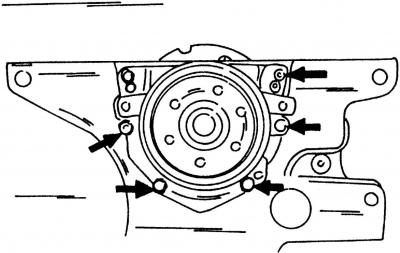

Pic. 385. The oil seal flange shown on the back of the engine must be replaced with the oil seal. Tighten the bolts (shown by arrows) torque 10 Nm

Then screw on the rear oil seal housing with a new gasket. Tighten the bolts shown in Figure 385 to 10 Nm.

Attention! The O-ring cannot be replaced separately - the entire gland flange must be installed.

Pic. 386. Installed oil pump. Tighten the bolts to a torque of 25 Nm

Attach the oil pump to the bottom of the crankcase (2 bolts, 25 Nm). On fig. 386 shows the places of their attachment.

Install the oil pan with a new gasket. Tighten the bolts in a circle with a torque of 20 Nm.

Install the engine intermediate plate (3 bolts, 10 Nm).

Install the flywheel. The bolts should be tightened evenly crosswise with a torque of 60 Nm. From the end position, turn all the screws another 90° (quarter turn) (without using a torque wrench).

Attention! Use only new bolts.

Install the clutch as described in the appropriate section. In this case, the flywheel must be fixed in a stationary position.

Install the crankshaft gear. Lubricate the bolt. Fix the crankshaft in a fixed position, preventing the flywheel from turning, and tighten the bolt to 90 Nm. From the end position turn the bolt another 90° (without using a torque wrench).

Attention! Use a new bolt.

Slide the intermediate shaft gear onto the shaft. There should already be a segment key on the shaft. Fix the gear wheel in a fixed position and tighten the bolt to 45 Nm.

Install the parts removed from the left side of the engine. Tighten the crankshaft position sensor to 10 Nm and the crankcase ventilation connection to 25 Nm.

Install vacuum pump with new O-ring (20 Nm).

Install the oil filter base with a new gasket (3 bolts, 25 Nm).

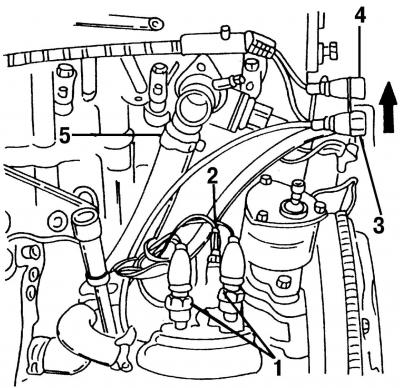

Pic. 387. Installing bracket 1 high pressure fuel pump and oil cooler 2

Screw the bracket 1 for mounting the injection pump (pic. 387) three bolts. Tighten the bolts to a torque of 20 Nm, and then tighten another 90°. Install the oil cooler with a new gasket. Tighten the nut at the bottom of the oil cooler to 25 Nm.

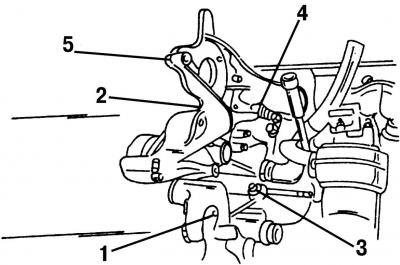

Pic. 388. The bolts of the supporting bracket for fastening the units are located in the places shown, the numbers indicate the order in which the fastening bolts are tightened

Install the support bracket for the units. Replace the cylinder block O-ring. Place the bracket on the pilot holes and screw in the five bolts. Connect the coolant hose to the oil cooler. At the same time screw on the oil filter (subsection 18.3). Tighten the units carrier bracket bolts in the sequence shown in fig. 388, torque 25 Nm.

Measure how far the pistons protrude (see 17.5.3) and select the cylinder head gasket according to the measured value.

Install the cylinder head (see 17.3.6).

Install the intake manifold with a new gasket and fasten it with six bolts (25 Nm).

Install the new exhaust pipe gaskets so that they point upwards, install the pipe together with the turbocharger and screw them on (25 Nm). Install oil recirculation hose, tighten O-ring banjo bolt (30 Nm) and screw on the heat shield (two nuts).

Connect the turbocharger oil line (union nut). Tighten it to 25 Nm. Tighten the hollow bolt in the cylinder head to 25 Nm.

Screw on the connecting pipe of the exhaust gas recirculation system (25 Nm).

Connect the auxiliary heating connector.

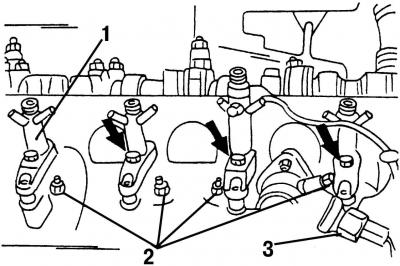

Pic. 389. Installation of nozzles and glow plugs: 1 - tension holder, 22 Nm; 2 - glow plugs, 15 Nm; 3 - wire tip

Install the nozzles together with the spikes. Tighten the solder joints with a torque of 22 Nm. On fig. 389 shows where the nozzles are attached.

Screw in glow plugs. Tighten them with a torque of 15 Nm (pic. 389). Connect the plug connector of the coolant temperature sensor on the right side.

Screw on the glow plug electric bus and install the oil drain hoses.

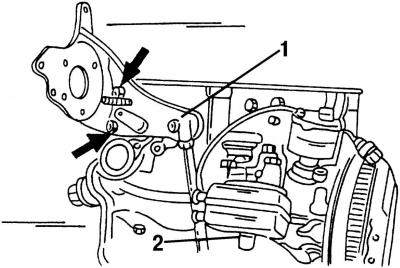

Pic. 381. Details to be removed: 1 - oil pressure switch; 2 - oil temperature sensor; 3 - crankshaft position sensor; 4 - needle lift sensor; 5 - coolant hose

Connect all wires to sensors (pic. 381). The blue/black wire plug is installed on the blue oil pressure switch, the yellow/black wire plug is installed on the gray oil pressure switch.

Install injection pump (see related section).

Install inner toothed belt guard (2 bolts on the cylinder head, 1 bolt on the high pressure fuel pump).

Install the injection pump gear. Put on the segment key first. Lock the gear wheel in a fixed position and tighten the nut to 55 Nm. Tighten also the tension roller of the toothed drive belt, without tightening it completely.

Install the V-ribbed belt as described in the relevant section. Having fixed the camshaft gear in a fixed position, tighten the mounting bolt to 45 Nm.

Connect the fuel supply lines to the injection system. Tighten the cap nuts to 25 Nm. Connect a nearby plug.

Install the cylinder head cover. Use a new gasket. Tighten the nuts to 10 Nm and put on the protective caps. Connect the ventilation hose. After that, install the toothed drive belt guard now.

Screw on the front engine mount clamp. Tighten the bolts to 60 Nm.

Set the generator (25 Nm).

Slide the crankshaft pulley through the dowel pin onto the crankshaft camshaft gear and tighten the bolts. Tighten the bolts to 25 Nm. Screw on the water pump pulley (23 Nm).

Screw on the thrust bearing of the drive shaft (43 Nm) and turbocharger support collar (25 Nm).

Carry out all work not specifically mentioned in the reverse order of the disassembly process.

Visitor comments