- generously lubricate the valve stems with engine oil and insert them into the appropriate guide bushings;

- install the lower valve plates;

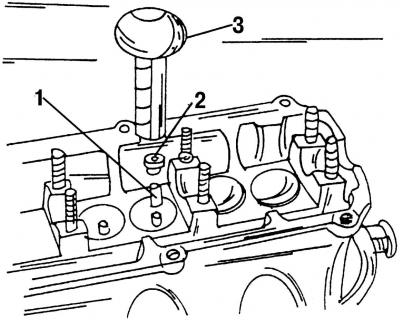

Pic. 405. Installation of oil seals: 1 - plastic sleeve; 2 - oil deflector cap; 3 special tool 10-204

- using special tool 10-204 (pic. 405), install oil seals;

- push the plastic sleeve 1 of the special tool onto the protruding part of the valve guide. A plastic sleeve protects new valve stem seals from damage that they can get when they come into contact with sharp grooves on the valve stems;

- lubricate oil scraper cap 2 well and put it on a plastic sleeve;

- put tool 3 on the oil seal and carefully push it into the guide bush. Be aware that if the valve stem seals are installed without using this special tool or a similar tool, they may be damaged, resulting in increased oil consumption. In extreme cases, you can use a piece of pipe of a suitable diameter, but be extremely careful not to damage the flinger caps or spring rings.

If the valves have been lapped, then each valve must be installed in the seat to which it was lapped.

Install one inner and one outer spring for the respective valve in the cylinder head (if old springs are installed) mount them with a valve puller.

Tap the top of the valve stem with a plastic mallet. In this case, incorrectly installed valve stem halves will fly out of their seat. In order not to lose them, put a rag around the end of the springs.

Insert the pushers in accordance with the marked marks in the holes (lubricate them well), if old pushers are used.

Lubricate the camshaft generously with oil at the bearing locations.

Install the camshafts in the box and rotate them several times. Install the shafts so that both cams of the first cylinder on the two shafts look up.

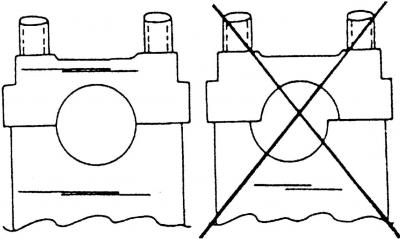

Pic. 406. When installing the camshaft bearing caps, be sure to follow the correct location

Bearing caps should only be installed as shown in fig. 406 and only in accordance with the method described below, so that the camshaft is not deformed.

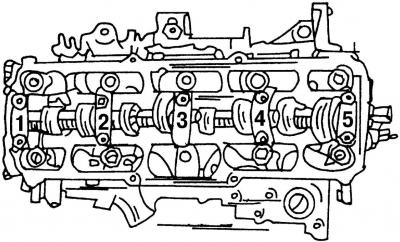

Pic. 407. Numbering of camshaft bearing caps. Covers are installed in the sequence shown

Guided by Fig. 407, put on the bearing caps No. 2 and No. 4 and install the nuts by hand. Since the bearing caps are misaligned, check that they are seated correctly. For this, guided by Fig. 406, determine if the covers have been put on correctly.

Tighten the nuts of the installed bearing caps alternately and crosswise in several passes to a tightening torque of 20 Nm. Make sure that the surface of the covers is opposite the surface of the cylinder head.

Fit caps no. 5, 1 and 3. Tighten the nuts alternately and crosswise in several stages to a tightening torque of 20 Nm. The numbering of the bearing caps corresponds to the numbering shown in fig. 407. This figure should be followed when installing the camshaft.

Take the camshaft oil seal and see which side the spring is on. The side on which the spring is located should be directed inward. Lubricate the sealing surface and the rolling surface of the camshaft. To install a new stuffing box, you can use a pipe of a suitable diameter. The pipe must fully match the size of the outer part of the stuffing box. Push the seal straight on and strike it until the outer surface of the seal is completely inside. You can install the oil seal in the same way as described for installing the crankshaft front oil seal.

Install the timing pulley on the camshaft (don't forget the wedge) and tighten the bolt with washer. Keeping the camshaft stationary (e.g. using an old timing belt) tighten the bolt to 45 Nm.

Install the intake pipe and exhaust manifold to the cylinder head (use new gaskets).

Install four injectors and glow plugs.

Install all removed parts.

Visitor comments