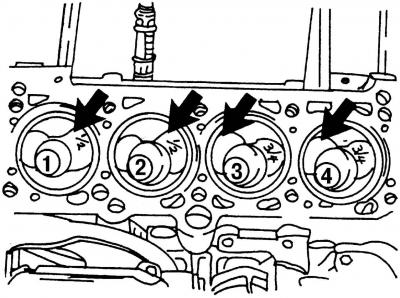

Pic. 422. View of the top of the engine. The arrows show the large inlet valve recesses, which are positioned differently on pistons #1 and 2, #3 and 4

Mark each piston and connecting rod with the number of the cylinder from which they were removed. This is best done by marking the cylinder number in color on the bottom of the piston. Draw an arrow on the bottom of the piston pointing to the front of the engine. Since the piston can be placed in reverse, i.e. rotated 180°, follow fig. 422.

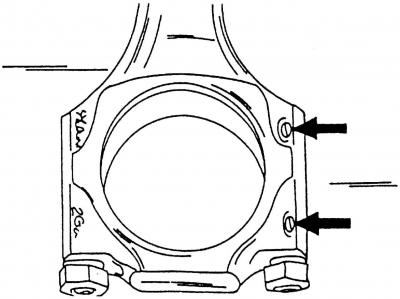

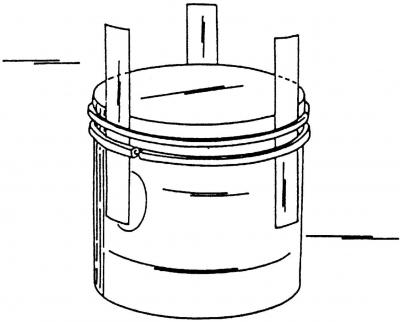

Pic. 423. The arrows show cast protrusions. The bearing shell tongues are located on the same side

When removing the piston with the connecting rod, observe the exact direction of installation of the connecting rod cover and immediately after removal, mark the cylinder number on the connecting rod and the connecting rod cover on the side. It is best to do this with a punch (for example, for cylinder No. 1 - one blow with a center punch, etc.). Connecting rods and connecting rod caps must be combined so that both cast lugs are located opposite each other (pic. 423). Both protrusions after installing the connecting rods must always be located on the side of the intermediate shaft, and point to the side of the engine where the drive belt is located.

On one side, the pistons have a cutout for oil-cooling nozzles to prevent the nozzles and pistons from colliding at bottom dead center. The pistons must be installed with this side to the injectors.

After removing the connecting rod bearing caps, replace the connecting rod bolts.

Mark the bearing shells to match the connecting rod and connecting rod cap. Also mark the top and bottom bearing shells on their backside with a marker.

Remove the connecting rod bearing caps and bushings.

Knock out the pistons and connecting rods with the handle of a plastic hammer from the inside of the cylinder block to the outside. If necessary, scrape off the oil deposits on the top of the cylinder with a scraper, but be careful not to damage the surface of the cylinder.

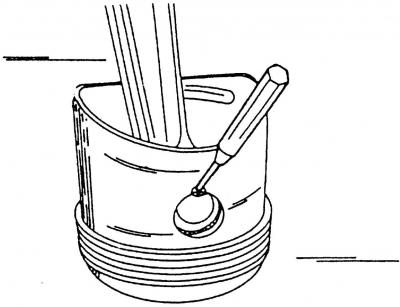

Pic. 424. Removing the retaining ring from the hole for the piston pin. For this, a sharp mandrel is used

Remove the safety collars and press out the piston pins. The notch in the piston pin hole makes it easier to use the tool, so you can easily remove the safety clips (pic. 424). Press out the finger with a suitable mandrel.

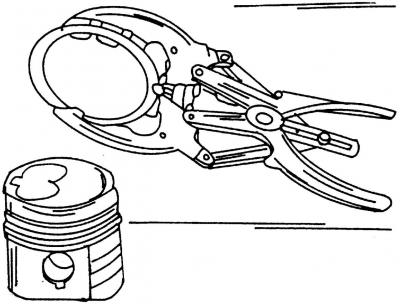

Pic. 425. Removal or installation of piston rings

Pic. 426. Schematic representation of the removal or installation of piston rings

Remove the piston rings one by one through the piston crown using a puller (pic. 425). If you plan to reinstall the rings, then they should be marked accordingly. If you do not have a piston ring remover, you can insert metal strips opposite each other under the rings. Be sure to place one of the strips under the lock of the ring in order to avoid scratches (pic. 426).

Visitor comments