Remove terminal «mass» wires with AB.

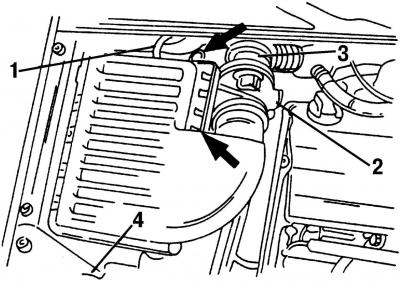

Pic. 390. To remove the air filter, disconnect: 1 - a hose going to the vacuum regulator of the exhaust gas recirculation system; 2 - mass air flow sensor; 3 - air intake; 4 - inlet hose

Remove the air filter as described (pic. 390).

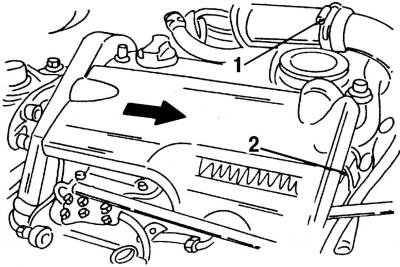

Pic. 391. Removing the engine cover: 1 - charge air hose; 2 - plug

Remove the engine cover and charge air hose. Remove plug 2 (pic. 391) and spring clip. Press the cover in the direction of the arrow to the side and disconnect the charge air hose 1 from the intake manifold.

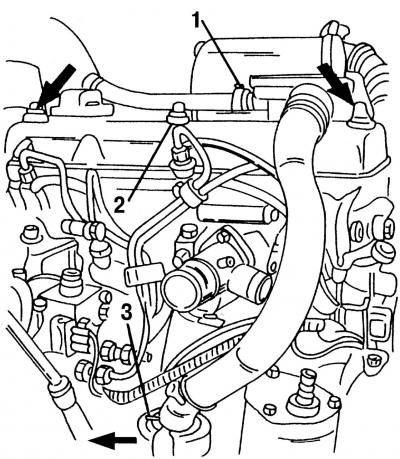

Pic. 392. Removing the cylinder head cover: 1 - hose; 2 - safety caps; 3 - spring clamp

Remove the cylinder head cover (the crankcase ventilation housing remains on the cylinder head). Disconnect hose 1 (pic. 392) from the cylinder block cover, loosen the spring clamp 3 of the inlet hose and disconnect the hose. Remove protective caps 2 (two are shown by arrows) and unscrew the three nuts located under them. Remove the cylinder head cover.

To dismantle the engine, it is necessary to lift the engine, remove the front hydraulic engine mount, engine mount clamp and remove the toothed belt. To do this, secure the engine with sling loops and raise it with a hoist in such a way as to unload the engine mount. Unbolt the engine mount from the hydraulic mount (2 bolts) and from the engine mount clamp (3 bolts). Always make sure the engine is securely fixed in the hanging position.

Raise the front of the car and remove the crankcase protection. Disconnect the power steering pump line bracket (1 bolt).

Loosen the engine mount clamp from the front of the engine. After unscrewing the bolts, immediately lower the car onto the wheels.

Remove the V-ribbed belt and the upper safety cover of the toothed drive belt.

Disconnect the two clips and remove the upper protection of the toothed drive belt.

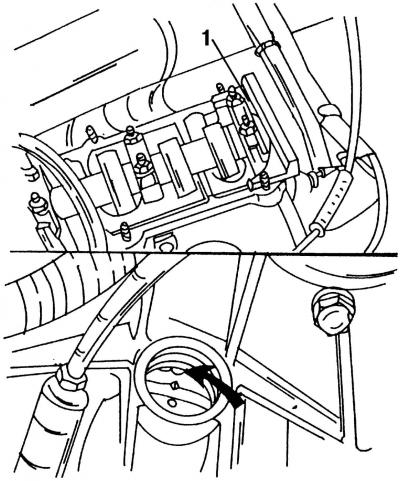

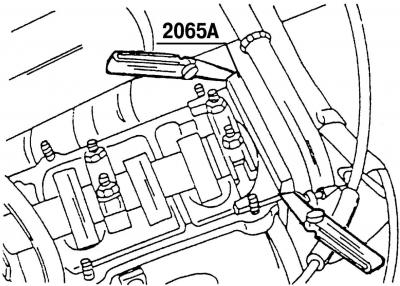

Pic. 415. The upper figure shows the adjusting gauge 1 mounted on the camshaft. The lower figure shows how the flywheel with the TDC mark should be located

For further work, a special tool is required (VW — 2065A, Ford — 21-105). The tool is a camshaft adjusting gauge that is installed on the flywheel side after the engine is at TDC. Rotate the engine so that the mark on the flywheel is in line with the adjusting pin (unscrew the plug from the top of the gearbox), as shown in Fig. 415. In order to make fine adjustment, you should perform the following work:

- turn the camshaft so that the end of the adjusting caliber is opposite the cylinder head;

- measure the gap on the other side with a feeler gauge;

- prepare a feeler gauge, the thickness of which is equal to half of the value found and slide it between the gauge and the cylinder head;

- now rotate the camshaft so that the gauge overlaps the probes;

Pic. 416. Both probes are inserted between the adjusting gauge and the surface of the cylinder head

- push a second feeler gauge of the same thickness from the other side between the gauge and the cylinder head. The operation is shown in fig. 416.

Put the front of the car on stands so that you can get to the bottom of the car.

Disconnect the crankshaft vibration damper (4 bolts) and water pump pulley (3 bolts). When performing this operation, the indicated shafts must be fixed in a fixed position.

Turn away three bolts and remove the bottom protection of a gear belt.

Lower the car back to the ground.

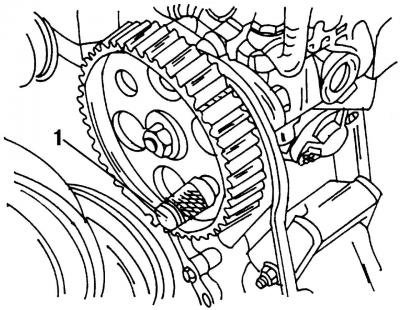

Pic. 417. Fixing the gear wheel of the high-pressure fuel pump in a fixed position with a latch 1

For the next operation, you will again need a special tool - 2064 (VW) or 23-047 (Ford), to be installed as shown in Fig. 417 on the gear wheel of the injection pump in order to fix it in a fixed position. The tool is a thrust pin with a diameter of 15.45 mm, which can be replaced with a round piece of any material. The thrust pin must be inserted through the hole in the injection pump pulley into the corresponding hole on the pump bracket.

Remove the timing belt guide roller located on top of the timing belt.

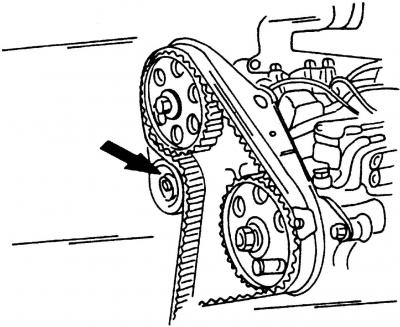

Pic. 418. After the tension roller, shown by the arrow, is loosened, it will be possible to remove the belt

If you plan to install the belt again, then a mark should be made on the belt, which should show the direction of its movement. After the nut is loosened, loosen the belt tensioner by turning it to the left. The device will release the belt (pic. 418, shown by arrow) and the tension will loosen.

Release the pulley and remove the drive belt from the gears.

Visitor comments