Lubricate the camshaft generously with oil at the bearing locations. Install the camshafts in their bed, and rotate them several times. Install the shafts so that both cams of the first cylinder on the two shafts look up.

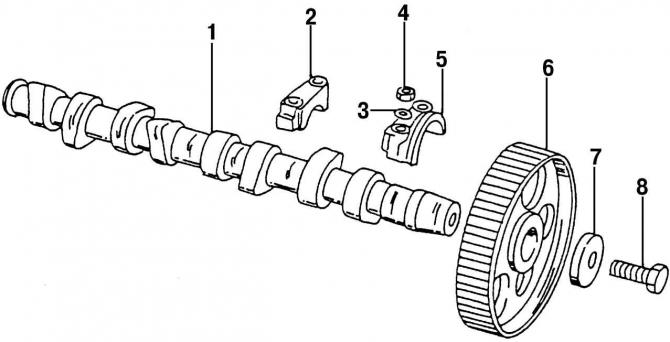

Pic. 435. Individual elements of the camshaft: 1 - camshaft; 2 - camshaft bearing cap; 3 - washer; 4 - nut, 20 Nm; 5 - rear bearing cover; 6 - camshaft gear; 7 - washer; 8 - bolt, 45 Nm

Guided by Fig. 435, put on bearing caps nos. 1, 3 and 5 and fit the nuts by hand. Since the bearing caps are misaligned, check that they are seated correctly. To do this, refer to Figure 406 to determine if the caps have been fitted correctly.

Tighten the nuts of the installed bearing caps alternately and crosswise in several passes to a torque of 20 Nm. Make sure that the surface of the covers is opposite the surface of the cylinder head.

Put on covers no. 2 and no. 4 and tighten the nuts. Tighten the nuts alternately and crosswise in several passes to a tightening torque of 20 Nm.

Take the camshaft oil seal and see which side the spring is on. The side on which the spring is located should be directed inward. Lubricate the sealing surface (the rolling surface of the camshaft should also be lubricated). To install a new stuffing box, you can use a pipe of a suitable diameter. The pipe must fully match the size of the outer part of the stuffing box.

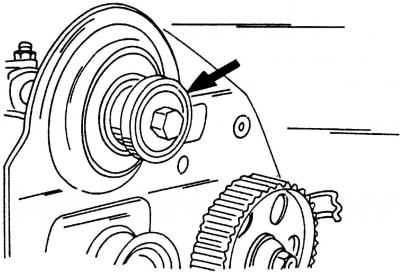

Pic. 439. Removing the camshaft oil seal using a special tool

Push the seal straight on and strike it until the outer surface of the seal is completely inside. The seal can also be installed in the manner shown in Fig. 439.

Install the camshaft gear to the camshaft (don't forget the wedge) and tighten the bolt with washer. Keeping the camshaft stationary (e.g. using an old timing belt) and tighten the bolt to 80 Nm.

Carry out the rest of the work in the reverse order of the removal process.

Visitor comments