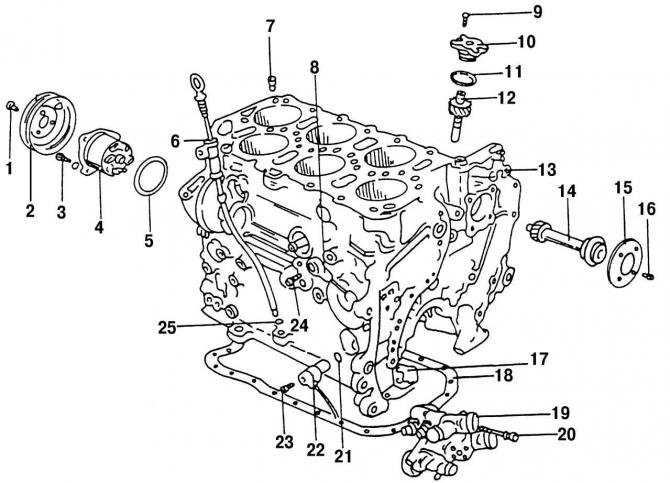

Pic. 69. Cylinder block with parts installed on it: 1 - bolt, 25 Nm; 2 - pulley of the cooling pump; 3 - bolt, 20 Nm; 4 - pump of the cooling system; 5 - O-ring, always replace with a new one; 6 - oil dipstick with guide tube; 7 - oil drain blocking, 5 Nm; 8 - knock sensor No. 2 (to correct the ignition timing); 9 - screw, 5 Nm; 10 - oil pump drive cover; 11 - O-ring, always replace with a new one; 12 - oil pump drive; 13 - cylinder block; 14 - intermediate shaft; 15 - adjusting washer, the inscription on it should look up; 16 - bolt, 10 Nm; 17 - O-ring, always replace with a new one; 18 - oil crankcase gasket; 19 - thermostat housing; 20 - bolt, 10 Nm; 21 - O-ring, always replace with a new one; 22 - crankshaft speed sensor; 23 - bolt, 5 Nm; 24 - bolt, 20 Nm; 25 - O-ring

Thoroughly wash the cylinder block 13 (pic. 69) and clean the oil passages. After blowing and drying with compressed air, inspect the cylinder block. Cracks in bearings or other places in the cylinder block are not allowed. Be sure to remove all residues of cleaning agents from the cylinder block.

Measure the clearance between the sides of the cylinder and the piston (see point 2.4.2).

The difference in the measured values of the inner diameter of the cylinder between the upper and lower chords indicates the taper of the cylinder bore, and the difference between the longitudinal and transverse directions indicates ovality. The inner diameter of the cylinder must nowhere differ by more than 0.08 mm from the nominal size.

Pistons of two repair sizes can be installed in the engine, for which, accordingly, it is necessary to bore the cylinder block (see point 2.4.2).

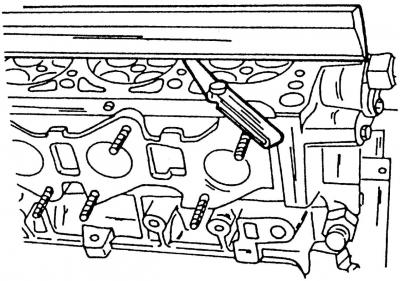

Pic. 46. Checking the cylinder head for deformation using a measuring ruler and a feeler gauge

Check the deformation of the surface of the cylinder block (as for cylinder head see fig. 46), for which measure the clearance of the cylinder block in the longitudinal, transverse and diagonal directions using a set of feelers. The gap should not exceed 0.10 mm. Before measuring, make sure that the surface of the cylinder block is thoroughly clean and that there are no foreign bodies between the dipstick and the surface of the cylinder block.

Visitor comments