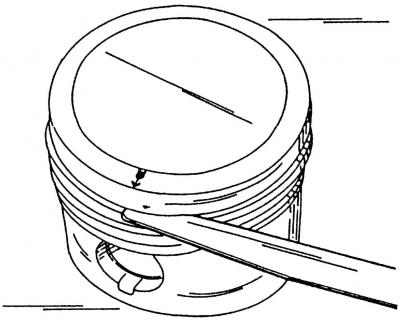

Pic. 62. Measuring the gap between the piston rings and the annular grooves in the piston head

- measure the clearance between the piston rings and the ring grooves in the piston head using a feeler gauge set (pic. 62). Nominal clearance for top and bottom compression rings 1 (pic. 63) is 0.02-0.07 mm, and for the oil scraper ring 2 - 0.02-0.06 mm. The maximum allowable wear gaps are 0.15 mm. If there is a gap, then either the ring or the annular groove of the piston is worn out;

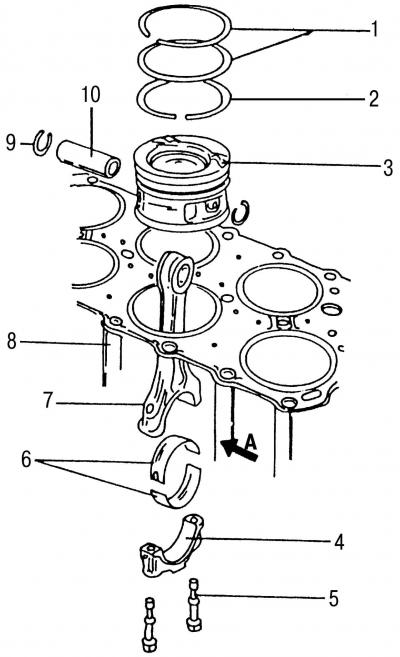

Pic. 63. Details of the piston group: 1 - compression piston rings; 2 - oil scraper ring; 3 - piston; 4 - connecting rod cover; 5 - connecting rod mounting bolt; 6 - connecting rod inserts; 7 - connecting rod; 8 - cylinder block; 9 - retaining ring; 10 - piston pin; arrow A points towards the front of the engine

- insert all piston rings one by one, starting from the bottom relative to the crankcase, into the cylinder bore. Turning one of the pistons upside down, push the rings down about 15 mm. After that, they will be directly in the cylinder bore;

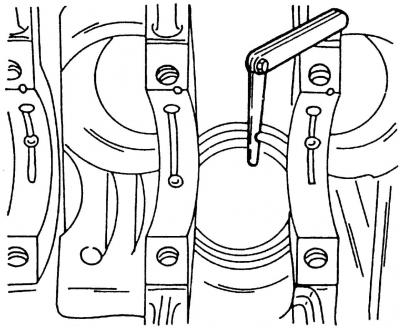

Pic. 64. Measuring the clearance of the piston ring locks in the cylinder bore

- insert into the cutout of the piston ring - into the lock, a measuring probe to determine the gap (pic. 64). For compression piston rings, the gap in the lock should be 0.2-0.40 mm, and for the oil scraper ring - 0.25-0.50 mm. The maximum permissible wear gap for all rings is 1.0 mm;

- if the gap in the lock is too small (e.g. on new piston rings, which must also be measured), then it needs to be increased. The rings are very fragile, so this work should be done carefully. It is best to clamp the file in a vise and grind off the end of the ring;

- Check piston pins and connecting rod bushings for wear and tear. Even if only one connecting rod is damaged, the entire assembly must be replaced;

- the connecting rod bolts on the VR6 engine are screwed directly into the connecting rods (no nuts are used) and are the so-called «malleable screws», which should be replaced after each unscrewing;

- check the connecting rods with a measuring device for twisting and bending.

Visitor comments