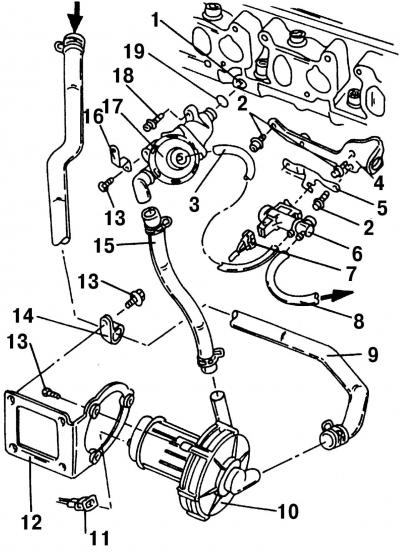

Pic. 99. Elements of the additional air supply system: 1 - air channel in the cylinder head; 2 - bolt, 25 Nm; 3 - vacuum hose; 4 - lifting eye; 5 - holder; 6 - additional inlet valve */**; 7 - plug block; 8 - vacuum hose; 9 - inlet hose; 10 - air pump motor *; 11 - plug block; 12 - holder; 13 - bolt, 10 Nm; 14 - hose clamp; 15 - hose under pressure; 16 - holder; 17 - combined valve; 18 - bolt, 15 Nm; 19 - O-ring ___________ * The condition of this part is monitored by the self-diagnosis device. ** The condition of the part is monitored in «final conclusion on faults»

After each subsequent start of the engine and until the engine temperature reaches 85°C, the auxiliary air supply system (pic. 99) turns on with a delay of 20 s and runs at idle speed of the engine for 5 s, while the system is controlled by a self-diagnostic device.

The condition of the parts of the auxiliary air supply system is monitored either in «final conclusion on faults», or if any defect appears, it will be recorded in the fault recorder. When accessing the fault memory (work is done at the service station), the malfunction is easily diagnosed and then can be corrected.

For some positions (pic. 99) the following additional explanations are given:

- additional air is injected into the air duct 1 of the cylinder head;

- lifting eye 4 is screwed on the left side of the cylinder head;

- a valve for supplying additional air is screwed into clamp 5;

- plug 7 is put on the inlet valve (black color);

- a vacuum hose 8 is connected between the top of the intake manifold and the fuel distribution line;

- the inlet hose 9 comes from the top of the air filter. Its connection must be tight, without air intake;

- plug 11 refers to the air pump motor. It is black and has two pins;

- holder 12 holds the air pump motor. It is screwed into the cooling fan air intake;

- hose clamp 14 secures the inlet hose;

- the pressure hose 15 is attached between the pump motor 10 and the combination valve 17;

- holder 16 secures the combination valve to the guide tube of the oil dipstick;

- always replace the O-ring 19.

Visitor comments