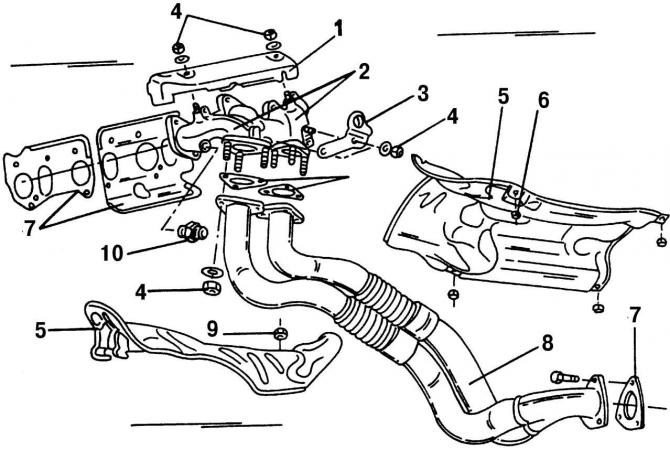

Pic. 100. Elements of the front of the exhaust system: 1 - engine thermal protection screen; 2 - exhaust manifold, consisting of two parts; 3 - lifting eye; 4 - nut, 40 Nm; 5 - engine thermal protection screen; 6 - nut of the engine thermal protection screen; 7 - gasket, for replacement; 8 - receiving pipe; 9 - nut, 10 Nm; 10 - fitting for connecting the EGR system, 35 Nm

Exhaust manifold 2 (pic. 100) consists of two parts and there are two separate gaskets 7. A fitting 10 is screwed into the manifold for connecting the exhaust gas recirculation system (EGR).

The exhaust manifold can be removed after the heat shield 5 has been removed and both exhaust pipes 8 have been disconnected.

Installation of the exhaust manifold is carried out in the reverse order of removal, while observing the following recommendations:

- always change the gasket between the engine and the exhaust manifold. When installing a new gasket, make sure that it is installed in the correct position;

- always replace the self-locking nuts 4 securing the exhaust manifold to the engine. They should be tightened with a torque of 40 Nm;

- replace the gaskets 7 between the exhaust pipes and halves of the exhaust manifold. The nuts connecting the exhaust manifold and downpipes are self-locking and should therefore always be replaced. Tighten the nuts to a torque of 40 Nm.

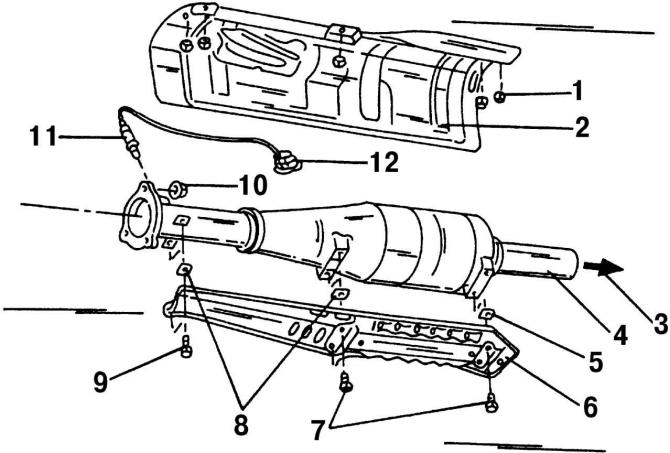

Pic. 101. Elements of the middle part of the exhaust system (located between the exhaust pipe and the catalyst muffler): 1 - nut of the thermal protection screen; 2 - thermal protection screen; 3 - direction to the first muffler; 4 - catalyst; 5 - protective collar; 6 - thermal protection screen; 7 - bolt, 10 Nm; 8 - protective collar; 9 - bolt, 10 Nm; 10 - nut, 40 Nm; 11 - lambda probe; 12 - black plug

Catalyst 4 (pic. 101) installed after the downpipe. He looks like «swollen» silencer and consists of a large number of metal or ceramic honeycombs, which are coated with platinum or similar metals. Exhaust gases pass through these cells. Platinum speeds up a chemical reaction that turns harmful gaseous wastes into harmless gases. The lambda probe 11 installed in front of the catalyst constantly measures the amount of harmful CO gas contained in the exhaust gases and transmits information to the computer in the form of electrical signals, on the basis of which the required adjustment is carried out, that is, the composition of the combustible mixture changes.

Visitor comments