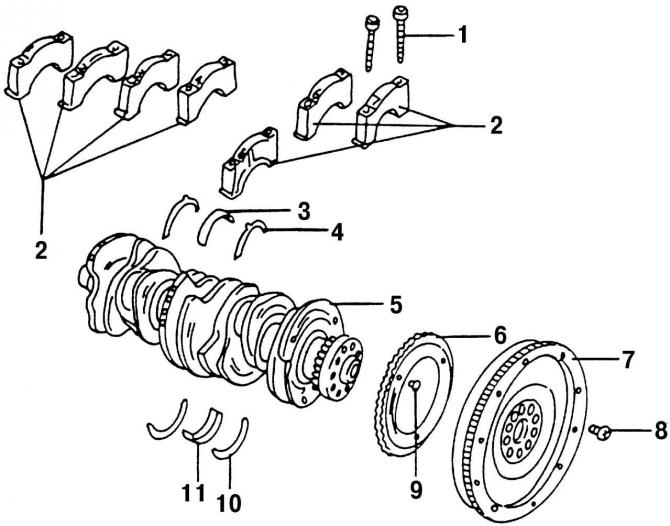

Pic. 82. Elements of the crankshaft and main bearings: 1 - bearing cover bolt; 2 - main bearing caps (main bearing No. 1 - from the side of the vibration damper); 3 - main bearing shell; 4 - adjusting thrust semi-ring bearing No. 5; 5 - crankshaft; 6 - toothed rim of the speed sensor; 7 - flywheel; 8 - flywheel mounting bolt, always a replacement; 9 - gear rim bolt; 10 - adjusting washer in the cylinder block for bearing No. 5; 11 - bearing shell of the cylinder block. Gear rim 6 of the speed sensor should always be changed if it was removed

- install the gear rim on the crankshaft 6 (pic. 82) speed sensor with a new bolt 9;

- install the tubes in the oil channels of the main bearings No. 2 and 7 and fix them with a sharp punch;

- wipe the blind holes in the sockets of the cylinder block and insert bearing shells lubricated with engine oil (with grooves for lubrication) so that the protrusions of the liners enter the blind holes;

- insert into the middle main bearing (bearing number 5) persistent half rings;

Attention! Thrust half rings should be directed by grooves to the friction surface of the crankshaft.

- place the crankshaft in the bearing shells. If the connecting rods are in the cylinder block, install the connecting rod bearings on the crankshaft journals;

- insert the bottom liners (without oil grooves) main bearings in the appropriate caps (protrusions into recesses) and generously lubricate their surfaces with engine oil;

- lubricate with engine oil and install, lining out, the other two thrust half rings on the bearing cover. The oil grooves must be located against the crankshaft;

- install the main bearing caps and lightly tap them with a rubber or plastic hammer;

- tighten the bearing cap bolts in several stages, starting with the middle one, with a tightening torque of 30 Nm. Then turn each bolt another half turn. After tightening the bearing caps, rotate the crankshaft a few times to make sure it rotates easily without binding;

- check the axial free play of the crankshaft (see section 2.6.1);

- install pistons and connecting rods (see paragraph 2.4.6);

- install the front and rear crankshaft oil seals (clause 2.6.4);

Attention! The front and rear crankshaft oil seals should be changed each time the crankshaft or oil seal flanges are removed.

- lubricate the bearing journal of the intermediate shaft, install the shaft and tighten the mounting bolts with a tightening torque of 10 Nm;

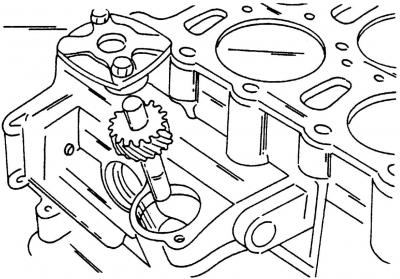

Pic. 79. Removing the oil pump drive shaft

- install the oil pump drive shaft with a new O-ring (pic. 79);

- install and adjust the timing gear, including the countershaft chain (see point 2.7.2);

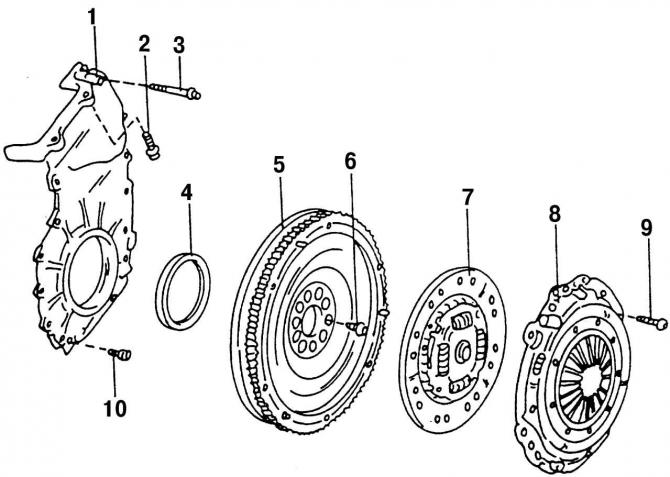

Pic. 85. Elements of the rear side of the engine: 1 - stuffing box cover; 2 - bolt, 25 Nm; 3 - bolt, 10 Nm; 4 - stuffing box; 5 - flywheel; 6 - flywheel mounting bolt; 7 - driven clutch disc; 8 - clutch pressure plate; 9 - clutch basket mounting bolt, 20 Nm; 10 - bolt, 10 Nm

- block the flywheel with a lock and install the flywheel 5 (pic. 85) on the crankshaft. Tighten new mounting bolts 6, tighten them to 70 Nm, then turn each bolt another quarter of a turn;

- install the clutch (see subsection 9.3) and tighten bolts 9 (pic. 85) clutch pressure plate 8 with a torque of 20 Nm;

- install oil pump (see point 4.2.2);

- put a new gasket on the sealant and install the oil pan. Bolts of fastening of an oil crankcase tighten the moment of 20 Н·м.

Carry out all further work in the reverse order of disassembly.

Visitor comments