- unscrew all the parts located on the cylinder head;

- clamp the cylinder head together with the clamp screwed to the exhaust manifold set screw in a vise;

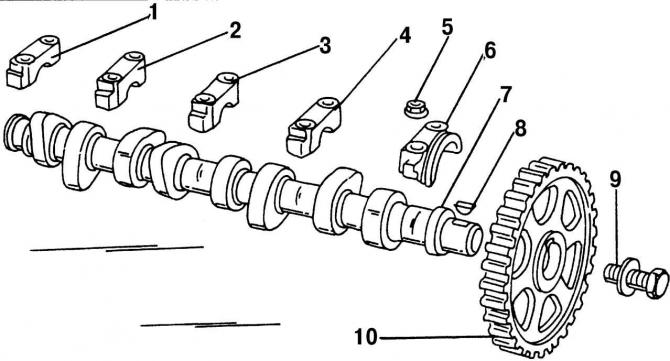

Pic. 108. Details of the camshaft: 1 - bearing cover No. 5; 2 - bearing cap No. 4; 3 - bearing cap No. 3; 4 - bearing cover No. 2; 5 - nut, 20 Nm; 6 - bearing cover No. 1; 7 - camshaft; 8 - segment key; 9 - bolt with washer, 80 Nm; 10 - camshaft gear

- loosen bearing cap nuts nos. 5, 1 and 3 (pic. 108) each two turns evenly and crosswise until both covers are unscrewed, remove the covers;

Note. Cover No. 1 may contain an O-ring for the cylinder head cover.

- remove the bearing caps No. 2 and 4 in the same way;

- remove the camshaft from the cylinder head bearings;

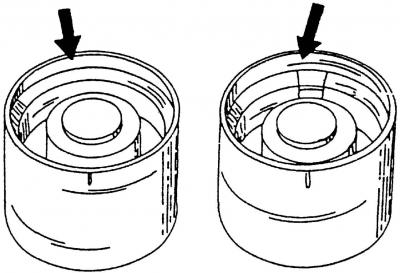

Pic. 109. Marking of hydraulic pushers

- put scratch marks on the inside of the pushers, i.e. the first pusher - one risk, the second pusher - two, etc. (pic. 109), since they should not be confused (the countdown is from the drive side of the gas distribution mechanism) and take out the pushers. Do not fold the pushers, but put the contact plane down;

Note. The tappets are equipped with hydraulic elements that regulate the gap in the valve actuator, and therefore they must be handled with care.

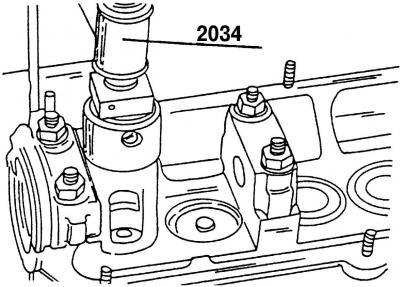

Pic. 110. Removing the valves using a puller 2034

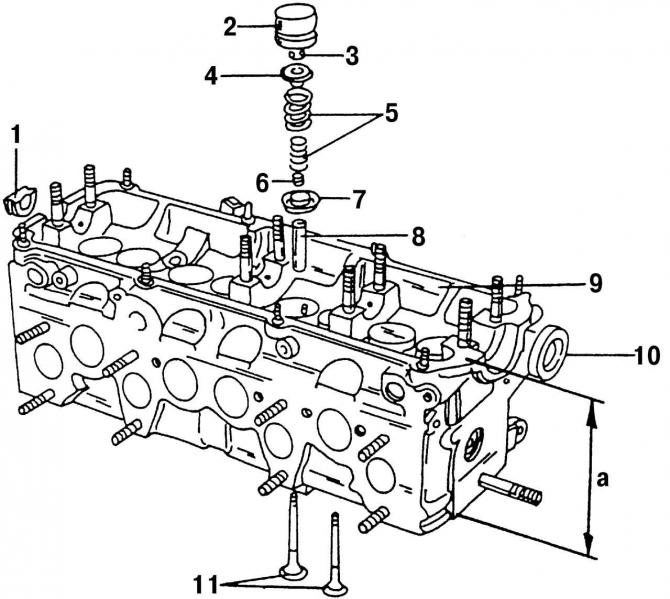

Pic. 111. Details of the valve drive mechanism: 1 - semicircular sealing ring; 2 - hydraulic pusher; 3 - valve stem halves (crackers); 4 - the upper plate of the valve spring of the valve; 5 - external and internal valve springs; 6 - oil deflector cap; 7 - lower plate of the valve spring; 8 - valve guide sleeve; 9 - cylinder head; 10 - camshaft seal; 11 - valves; a - cylinder head height

- the standard tool for removing and installing valves is tool number 2034 (pic. 110). It is attached to the cylinder head. Release valve 11 (pic. 111) from valve stem halves (crackers) 3, compressing the springs 5 with tool 2034;

- to remove the valves, you can also use a piece of pipe that is put on the upper spring plate. Under the valve plate on the other side, you need to put something to fix it. Tap the pipe briefly with a hammer until the valve stem halves come out. They will stay inside the pipe. But do not tear off the pipe from the spring plate, so as not to lose half of the valve stem;

- take out the top plate 4 (pic. 111) with springs 5, turn the cylinder head 9 and remove the valve 11 from the underside;

- remove the oil deflector cap 6 from the guide sleeve 8;

Note. Always replace oil seals with new ones.

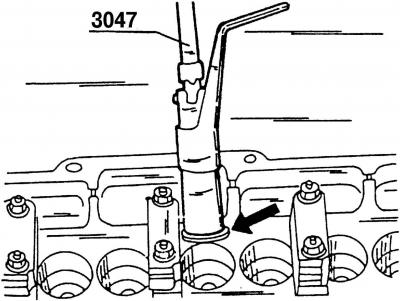

Pic. 112. Removing the lower plate of the valve springs using special pliers 3047

- with special tool 3047 (pic. 112) or using round-nose pliers, remove the lower plate 7 of the spring from the hole.

Visitor comments