- generously lubricate the inner surfaces of the cylinders with engine oil;

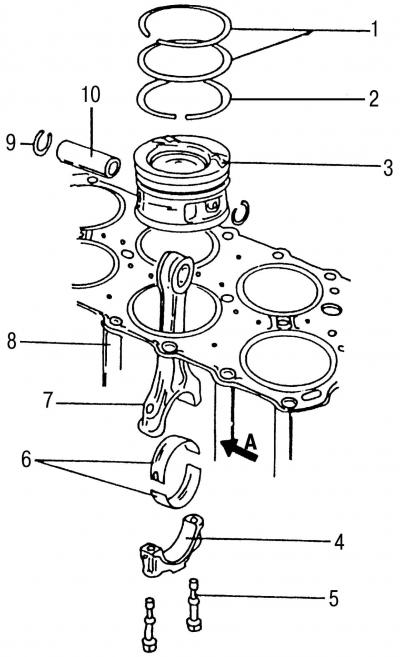

Pic. 63. Details of the piston group: 1 - compression piston rings; 2 - oil scraper ring; 3 - piston; 4 - connecting rod cover; 5 - connecting rod mounting bolt; 6 - connecting rod inserts; 7 - connecting rod; 8 - cylinder block; 9 - retaining ring; 10 - piston pin; arrow A points towards the front of the engine

- Arrange all connecting rods according to cylinder numbers. The cast lugs on the connecting rod and connecting rod cap must point towards the crankshaft pulley (pic. 63). After installing the connecting rods, the cast lugs must be located on the other side of the arrow;

- the arrows on the bottom of the pistons must point towards the front of the engine;

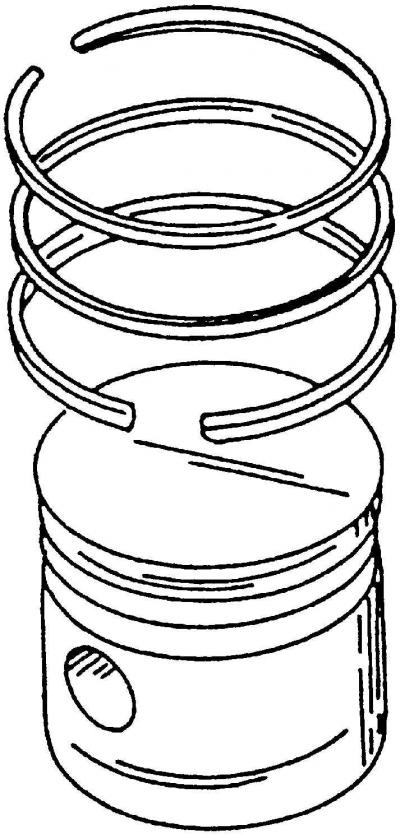

Pic. 134. The location of the locks of the piston rings relative to each other

- position the piston ring locks relative to each other at an angle of 120°on the surface of the cylinder (pic. 134);

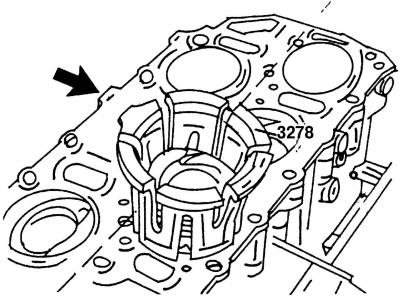

Pic. 66. Piston installation with special tool VW3278

- slide the 3278 band clamp onto the piston rings on the piston (pic. 66), and press the piston rings into the piston grooves;

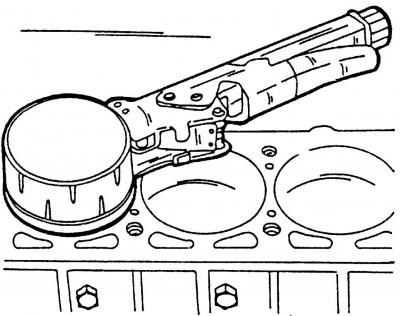

Pic. 67. Alternative band clamp for piston installation

- For this purpose, you can use the company's «Volkswagen» assembly tool - band clamp (pic. 67);

- check that the piston rings are fully engaged in their grooves;

- turn the crankshaft so that the two connecting rod journals of the crankshaft are at BDC;

- install the connecting rod bearing shell into the connecting rod;

- insert the connecting rod from above into the bore of the cylinder. To do this, lay the engine on its side so that the connecting rod can be directed towards the crankpin. Make sure that the cylinder bore and connecting rod neck are not scratched;

- insert the pistons in such a way that the piston rings in turn enter the holes of the cylinders and the heel of the connecting rod sits on the connecting rod journal of the crankshaft;

- insert the second liner into the bearing cap so that the bent tab of the liner sits in the groove of the bearing cap. Lubricate the bearing surfaces with engine oil;

- press the connecting rod cap against the connecting rod and lightly tap it. Lubricate the connecting rod bolts with engine oil and screw them in;

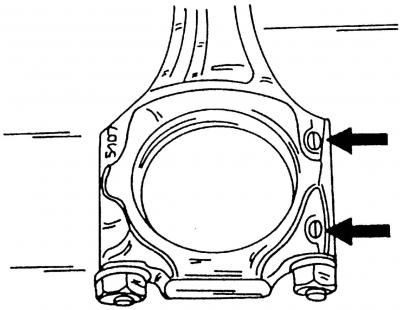

Pic. 56. Assembling the connecting rod and connecting rod bearing cap. The arrows show the protrusions

- be sure to double check that both molded lugs are positioned together (pic. 56). Both cast lugs on the connecting rod and connecting rod cap must be opposite each other and point towards the pulley;

- alternately tighten the connecting rod bearing bolts to a torque of 30 Nm, then tighten them another 90° (a quarter turn);

- after installing the connecting rod, rotate the crankshaft several times to make sure that it rotates easily, without jamming;

- check the markings of all connecting rods again to make sure that the arrows of the pistons point in the right direction;

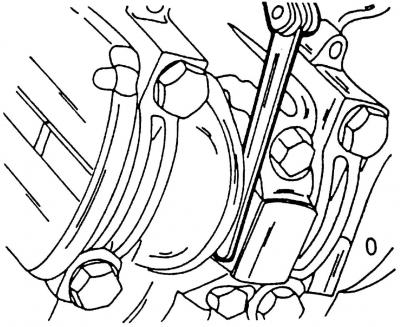

Pic. 68. Measurement of the axial clearance between the side plane of the connecting rod bearing and the side surface of the crankshaft

- with a probe (pic. 68) measure the axial clearance of the connecting rods mounted on the crankshaft so that the degree of wear of the parts can be assessed. To do this, press the connecting rod to one side so that you can insert the probe. If you can insert a feeler gauge with a thickness of more than 0.37 mm, then most likely the connecting rods have worn out in places of pressure. In the worst case, the places of pressure of the crankshaft were worn out;

- install oil pan (see subsection 4.1);

- all further assembly work is carried out in the reverse order of disassembly.

Visitor comments