- remove the cover of the ignition distributor;

- Disconnect the Hall sensor connector from the ignition distributor. For what, compress the spring clamp and pull out the plug;

- crank the engine until the piston of the first cylinder is in the TDC position of the compression stroke:

Pic. 219. The position of the TDC of the engine: A - on the engine installed on the car; B - on the engine removed from the car

- on the engine installed on the car, the mark «0» (pic. 219, A) on the flywheel should be in line with the edge «window» in the flywheel housing;

Pic. 220. The location of the mark on the outer side of the camshaft gear, when the piston of the first cylinder is set to the TDC position of the compression stroke

- on the removed engine, the groove on the vibration damper must align with the arrow on the drive belt guard (pic. 219, V), and the adjustment mark on the camshaft pulley (pic. 220) should be in line with the arrow on the drive belt cover.

Pic. 221. Places for drawing marks on the slider and the edge of the ignition distributor housing

- set the ignition distributor slider to the indicated position (pic. 221), before it is removed. Mark the top of the slider and the edge of the ignition distributor housing by scratching the risks;

- put a socket head on the vibration damper bolt to turn the engine.

- unscrew the bolt and remove the clamping rail of the ignition distributor;

- Pull the ignition distributor out of the engine.

The ignition distributor is installed in the reverse order of removal.

If the engine was cranked after the ignition distributor was removed, do the following:

- on the engine installed on the car:

- set the piston of the first cylinder to the TDC position during compression, i.e. both valves must be closed (if the cylinder head cover is removed), or crank the engine until the mark «0» (pic. 219, a) on the flywheel will not be in line with the edge «window» in the flywheel housing;

- on the engine removed from the car:

- rotate the engine until the groove on the vibration damper aligns with the arrow on the drive belt guard (pic. 219, V), while the adjustment mark on the outer side of the camshaft gear should lie opposite the TDC mark located on the inner metal wall (pic. 220);

Pic. 222. Alignment of the receiving pin of the oil pump shaft before installing the ignition distributor. The axis of the trunnion runs parallel to the axis of the crankshaft

- check the position of the oil pump shaft bearing journal. trunnion axis (pic. 222) must run parallel to the axis of the crankshaft. If necessary, the shaft journal can be aligned with pliers;

- orient the ignition distributor slider according to the previously applied risks on the slider and on the edge of the ignition distributor housing (pic. 221);

- in this position of the slider, put on the cover of the ignition distributor and secure it with clips;

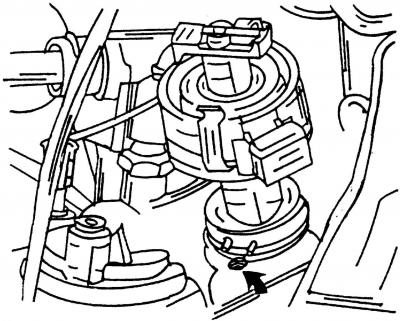

Pic. 223. Installing the ignition distributor

- orient the ignition distributor (pic. 223, shown by an arrow) and install it on the engine;

- connect the three-pin plug of the ignition distributor;

- adjust ignition timing (see subsection 8.6), by turning the ignition distributor housing.

We advise you to contact the service station to conduct an accurate check and adjustment of the ignition timing, which is carried out using a special tool.

Visitor comments