The distance between the electrodes of the spark plugs is presented in the table of adjustments and control.

Before turning out the candles, clean the wells in which the candles are located so that after removing the candles, dirt does not get into the holes for them. To remove the spark plugs, only a specially designed wrench should be used, and the HV wires from the spark plugs on the VR6 engine can only be removed with a special tool.

When working with spark plugs, observe the following rules:

- when removing the HV wire from the spark plug, do not pull on the wire itself, but only on the tip of the HV wire;

- after removing the candles, fold them in the sequence of the cylinders;

- if, during removal, some kind of candle has boiled, you do not need to use force, as you can strip the threads in the cylinder head made of light alloy. In this case, as an exception, try to remove the candle, warming up the engine to operating temperature, observing the precautions;

- Before installing new spark plugs, wait until the engine has cooled down. Otherwise, the thread will be overtightened (due to thermal expansion of the cylinder head material);

- spark plugs should be tightened to 30 Nm (2.0 liter engine) or 25 Nm (VR6 engine);

- if there is no torque wrench, then wrap a new candle without force with a candle wrench so that the sealing ring sits in its place, then tighten it another 90°with a spark plug wrench. If you install old candles, then tighten them by about 15°.

In company maintenance schedules «Volkswagen» it is prescribed to replace the spark plugs every 60,000 km or every 3 years. Even if the spark plugs work without problems, they should still be replaced at the recommended intervals.

Adjusting the gap between the electrodes of the candle

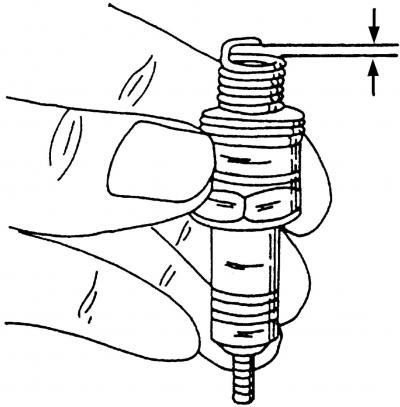

Pic. 224. The gap between the central and side electrodes of the spark plug. The probe must be inserted into the gap between the electrodes

Before installing the spark plug, check and adjust the gap between the center and ground electrodes (pic. 224).

This operation must be carried out before the winter operation of the car. The gap between the electrodes of the candles should be in the range of 0.7-0.9 mm.

In operation, this gap is constantly increasing due to the natural wear of the contact material. An increase in the gap leads to an increase in the breakdown voltage, which causes a violation of sparking and increased fuel consumption.

You need to check the gaps between the electrodes using a round probe. A flat probe does not take into account the heterogeneity of electrode wear and can give a large error in measuring the gap.

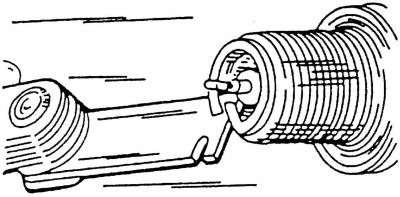

Pic. 225. Gap adjustment with a special tool

You can increase or decrease the gap between the electrodes only by bending the side electrode using a special tool (pic. 225). To do this, put the hook of the instrument on the side electrode and carefully bend or unbend it.

Visitor comments