Engine 2.0L

Remove the oil pump of a 2.0-liter engine in the following order:

- put the front of the car on trestle to gain access to the oil pan and oil pump;

- remove the oil pan (see subsection 4.1);

- unscrew the bolts of the oil pump housing;

- pull the pump down, the pump shaft gear should disengage from the countershaft gear, then pull it out completely;

- remove the ignition distributor (since it will still need to be removed when installing the pump).

Installing the oil pump is carried out in the reverse order of removal, subject to the following recommendations:

- when installing the oil pump on the crankcase, the gasket is not placed;

- tighten the pump mounting bolts with a torque of 20 Nm;

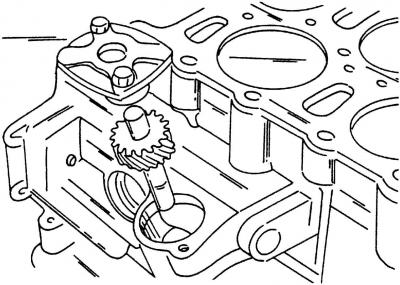

Pic. 167. The position of the landing neck of the oil pump drive shaft before installing the ignition distributor

- before installing the ignition distributor, install the oil pump drive shaft mounting journal so that the trunnion is parallel to the longitudinal axis of the crankshaft (pic. 167);

- install the ignition distributor and tighten the mounting bolts to a torque of 20 Nm (see chapter 8.5.3).

VR6 engine

Remove the VR6 engine oil pump in the following order:

- place the front of the car on stands to gain access to the oil pan and oil pump;

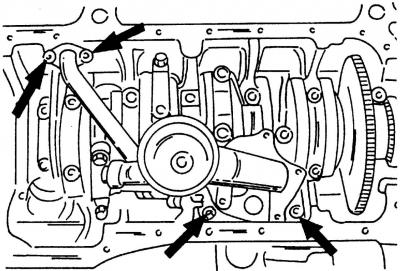

Pic. 168. The attachment points of the oil pump at the bottom of the crankcase of the VR6 engine are shown by arrows

- unscrew the bolts (pic. 168) fastening the oil pump housing and the oil receiver flange from the engine crankcase;

- pull the pump down, the pump shaft gear should disengage from the countershaft gear, then pull it out completely;

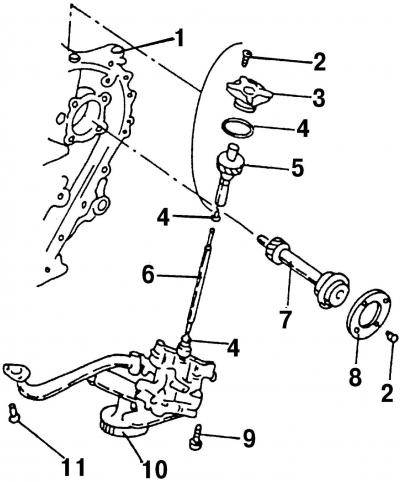

Pic. 165. Oil pump parts: 1 - cylinder block; 2 - bolt, 10 Nm; 3 - oil pump drive cover; 4 - O-ring, always a replacement; 5 - drive gear; 6 - pump drive shaft; 7 - intermediate shaft; 8 - adjusting washer; 9 - bolt, 25 Nm; 10 - oil pump; 11 - bolt, 10 Nm

- if you need to remove the drive gear 5 (pic. 165), then unscrew the fastening bolts 2 and remove the cover 3. The cover has an O-ring seal 4. Pull out the gear using wire cutters.

Installing the oil pump is carried out in the reverse order of removal, subject to the following recommendations:

- when installing the oil pump on the crankcase, the gasket is not installed, however, AMV188 001 02 sealant should be applied to the oil receiver flange;

- tighten the oil pump mounting bolts to a torque of 25 Nm, and the oil receiver bolts to 10 Nm;

- if the drive gear was removed, then insert it into the hole on the upper side so that it engages with the gear on the intermediate shaft;

- lubricate the cap and O-ring well with engine oil before installation;

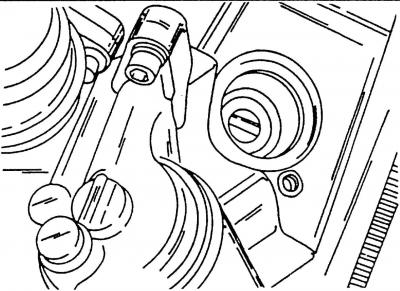

Pic. 169. Installing the drive shaft and cover with an o-ring

- insert the drive shaft, install the O-ring seal on the cover (pic. 169);

- tighten the cover fastening bolts to 10 Nm;

- Install the oil pan and tighten the oil drain plug to 30 Nm.

Visitor comments