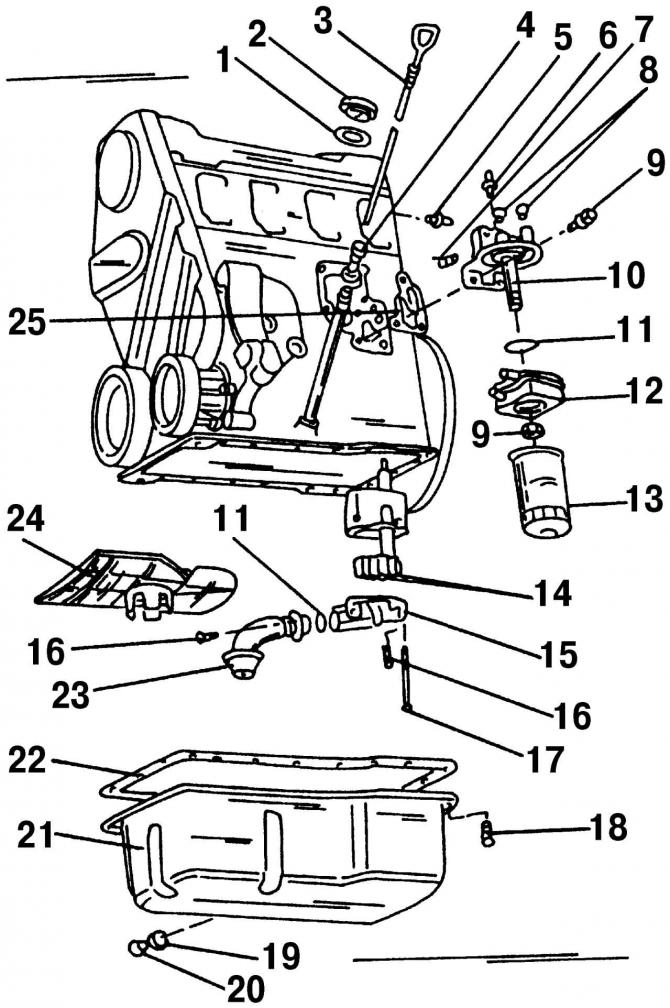

Pic. 166. Lubrication system of a 2.0-liter engine: 1 - gasket, replace with a new one; 2 - oil filler cap; 3 - dipstick for checking the oil level; 4 - dipstick guide tube for checking the oil level; 5 - oil pressure switch at 25 kPa; 6 - oil pressure switch at 180 kPa; 7 - check valve, 5 Nm; 8 - plugs; 9 - nut, 25 Nm; 10 - base of the oil filter; 11 - O-ring, always replaceable; 12 - oil cooler; 13 - oil filter; 14 - oil pump gear; 15 - oil pump cover with pressure reducing valve; 16 - bolt, 10 Nm; 17 - bolt, 20 Nm; 18 - oil sump mounting bolt; 19 - sealing ring, replace; 20 - oil drain plug; 21 - oil pan; 22 - gasket, replace with a new one; 23 - oil receiver; 24 - oil guide plate; 25 - gasket, replace with a new one

- unscrew the plug 20 (pic. 166) oil drain holes and completely drain engine oil from the engine into a container prepared in advance;

Note. Dispose of old engine oil in accordance with environmental regulations.

- remove the engine crankcase protection;

- unscrew the fastening bolts 18 and remove the oil pan 21 together with the gasket 22.

Note. On a 2.0-liter engine, it is difficult to get to the oil pan bolts located on the flywheel side. At the service station, special bolt wrenches 3249 and 3185 are used for this.

Install the oil pan in the reverse order of removal, while observing the following points:

- always replace the old pan gasket with a new one. Make sure that the gasket does not move during installation;

- before installation, apply sealant to the contact surfaces of the oil pan and cylinder block «D2»;

- Tighten the oil pan bolts evenly and crosswise. Hex bolts are tightened to 20 Nm (engine 2.0 l) or torque 15 Nm (VR6 engine);

- fill the engine with 5.5 liters of engine oil if the oil filter was removed;

- if the oil filter has not been removed, fill in 5.0 liters of oil.

Visitor comments