Attention! If you removed the hex flange bolt, use a new bolt when installing. In this case, the weight of the car should not fall on the wheels, as this can lead to damage to the wheel bearings. Before removing the drive shaft, carefully clean the area around the connection point of the inner shaft joint to ensure that no dirt enters the gearbox.

Removal is carried out in the same way as described: after the steering knuckle is bent outward, unscrew the bolts of the shaft flange on the gearbox.

Removing the right drive shaft

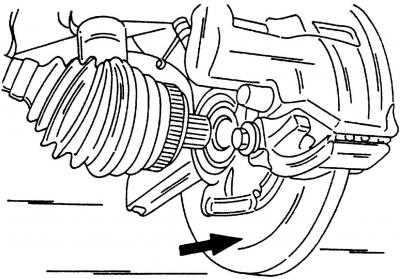

Pic. 260. To disengage the drive shaft from the wheel bearing housing, slide the wheel bearing housing outward while pulling the drive shaft in the opposite direction

Follow the instructions given until the end of the shaft is removed from the wheel bearing (pic. 260);

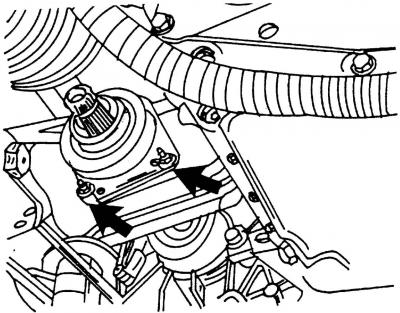

Pic. 247. Mounting bolts (shown by arrows) intermediate shaft bearing

- unscrew both bolts of the middle bearing (pic. 247) and remove the drive shaft completely from the gearbox.

After removing the drive shaft, the vehicle must not be moved, as otherwise the wheel bearing may be damaged. If the car still needs to be moved, then install the old CV joint instead of the shaft and tighten its fastening bolt to 50 Nm.

The installation of the drive shaft is carried out in the reverse order of the removal process, while:

- replace the circlip at the end of the drive shaft.

Installation of the left drive shaft

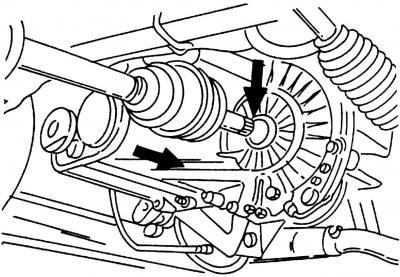

Pic. 261. Installation of the drive shaft. Insert a new retaining ring into the groove at the location indicated by the arrow

On an automatic transmission vehicle, insert the left drive shaft inner joint into the differential gear spline (pic. 261).

Using a plastic or rubber mallet, drive in the inner hinge until it stops. Do not damage the O-ring. To install the left drive shaft, do the following:

- thoroughly clean the splines of the drive shaft and the inside of the wheel hub from grease;

- insert the outer end of the drive shaft into the wheel bearing in the reverse order shown in fig. 260;

- screw a new bolt with shoulder and washer into the end of the drive shaft and tighten with a torque of at least 50 Nm;

- Install all removed parts of the front wheel suspension. The tightening torques for the connections are listed at the end of the book;

- install the wheel, lower the car on the wheels and tighten the nut to a torque of 150 Nm, and from the end position, already without a torque wrench, turn it another quarter of a turn (90°). Tighten the wheel bolts to 140 Nm;

- Check the transmission oil level and top up if necessary.

Installing the right drive shaft

Insert the drive shaft into the gearbox. Do not damage the sealing ring located in the gearbox housing.

- install the intermediate bearing of the drive shaft to the cylinder block (pic. 247);

- insert the outer end of the drive shaft into the wheel bearing slot and install a new bolt with a washer;

- other operations are carried out similarly to the installation of the left drive shaft.

By car with automatic transmission

Attach the drive shaft inner joint to the gearbox shaft flange. Tighten the bolts to 80 Nm;

- drive in the internal hinge of the shaft until it stops and tighten the bolts of the intermediate bearing;

- insert the outer joint of the shaft into the slot of the wheel bearing and tighten a new bolt with a shoulder and a washer and a torque of 50 Nm;

- other work is carried out similarly to the installation of the left drive shaft.

Visitor comments