- clean the splines of the drive shaft and treat with lubricant G 000 100;

- if the driven disk was removed, then it must be put on the spline of the input shaft of the gearbox and check how easily it slides back and forth along the shaft;

- when installing the gearbox, check the correct location of the intermediate plate of the engine and put the gearbox on the guide bushings;

- check if there are guide bushings in the cylinder block to center it with the gearbox. Otherwise, remove the guide bushings from the gearbox and insert them into the cylinder block;

- Raise the gearbox on a car jack, put it in the correct position, put it in the clutch and put it on the engine guide bushings. If, during installation, the input shaft of the gearbox does not fit into the splines of the hub of the clutch disc, ask an assistant to turn the crankshaft back and forth a little by hand, pulling the V-belt for this. As soon as the gearbox is against the engine, screw in and lightly tighten one of the mounting bolts;

- screw in the remaining gearbox mounting bolts located on the bottom surface and tighten them to a torque of 80 Nm;

- install the starter, wrap its mounting bolts and tighten them to a torque of 45 Nm;

Pic. 246. The locations of the mounting bolts (shown by arrows) suspension bracket on gearbox

- mount bracket mount (pic. 246) transmission suspension and pre-tighten the bolts by hand;

Pic. 245. Bolt locations (1 and 2) gearbox mounts

- adjust the position of the engine and gearbox relative to each other and screw the suspension mount by hand (pic. 245);

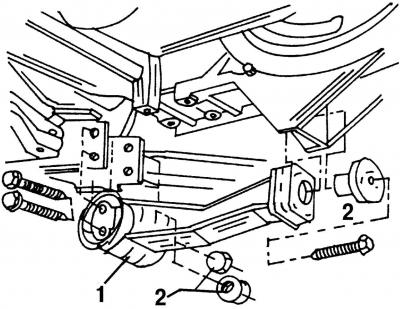

Pic. 244. Equalizer mount (pendulum) gearbox mounts: 1 - balancing suspension; 2 - bolts and nuts for fastening the balancing suspension

- mount the balancing (pendulum) (pic. 244) gearbox suspension. Wrap bolts and nuts and tighten them with a torque of 100 Nm;

- tighten bolt 1 (pic. 245) suspension fastening with a torque of 20 Nm, and a nut on bolt 2 with a torque of 100 Nm;

- tighten the bolts (pic. 246) suspension mounts with a torque of 90 Nm;

- install a new thrust ring on the end of the left drive shaft;

- insert the left drive shaft into the slot and push it in with a short push, if necessary, hit the outer end of the shaft with a plastic hammer so that the retaining ring fits into the groove on the inside of the differential gear;

- insert the outer end of the left drive shaft into the wheel hub;

- install a new thrust ring on the end of the right drive shaft;

- insert the right drive shaft in the same way as the left one. The retaining ring should fit into its groove and snap into place;

- install the intermediate shaft retaining ring;

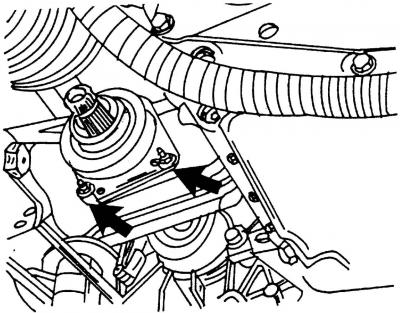

Pic. 247. Mounting bolts (shown by arrows) intermediate shaft bearing

- insert intermediate shaft (pic. 247), if necessary, drive in the shaft with a plastic hammer;

- tighten the intermediate shaft bearing mount to 27 Nm;

- install the connecting rod with the suspension strut. Tighten the nut to 100 Nm;

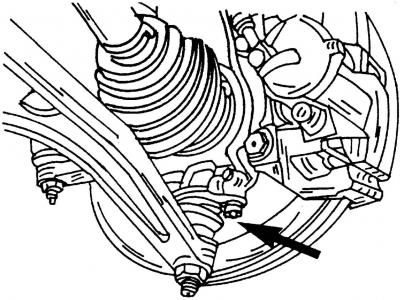

Pic. 242. The location of the attachment of the carrier suspension arm to the steering knuckle (shown by arrow)

- connect wheel bearing housing (rounded fist) with ball joint and tighten the two bolts (pic. 242) fastening the carrier suspension arm to the steering knuckle with a torque of 55 Nm;

- Install the tie rod head. Tighten the nuts to a torque of 30 Nm, then tighten them another 90°;

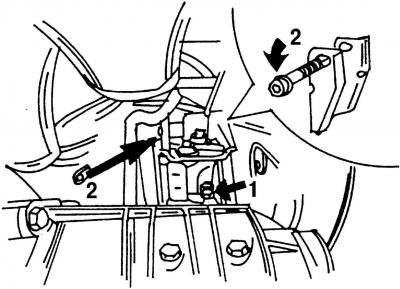

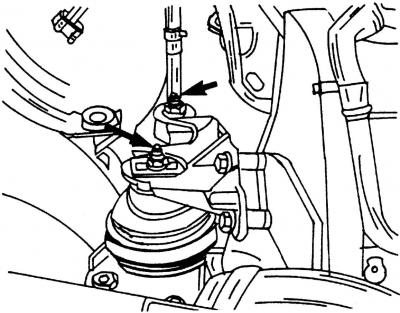

Pic. 241. Fastening nuts (shown by arrows) right engine mount

- mount the right suspension mount (pic. 241) engine. Tighten the fastening nuts to a torque of 50 Nm;

- wrap the upper bolts of the gearbox to the engine and tighten them to a torque of 80 Nm;

- screw the wire «masses»;

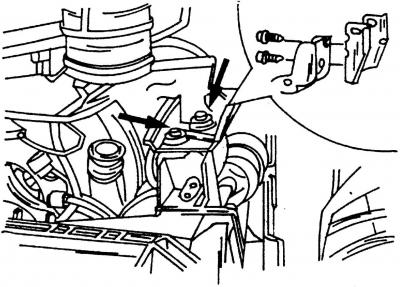

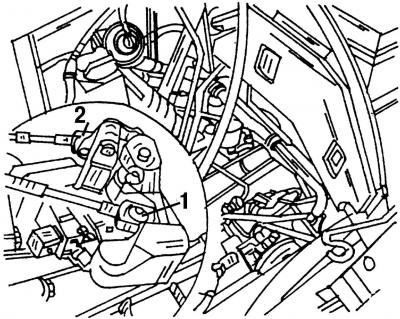

Pic. 239. Attaching cables to gear levers: 1 - gear selection lever; 2 - gear lever

- insert both shift cables into the clamps on the gearbox until they stop. Rope 1 (pic. 239) must cross cable 2;

- Slide the ends of the cables onto the respective levers on the gearbox. Put cable 1 on the gear selection lever, and cable 2 on the gear lever;

- press the pipeline into the holder on the gearbox and connect it to the clutch slave cylinder;

- fix the pipeline with a bracket;

- install the air filter housing;

- install the lower casing of the engine compartment;

- install the front wheels. Turn the wheels on and lower the car. Tighten the wheel bolts in a crosswise manner to 170 Nm. Tighten the hub center bolt;

- connect wire «masses» to AB;

- bleed the air from the hydraulic clutch system (see 9.4.3);

- adjust the gearshift drive;

- check the gear oil level in the gearbox. If there is not enough, add it to the gearbox.

Visitor comments