Removing

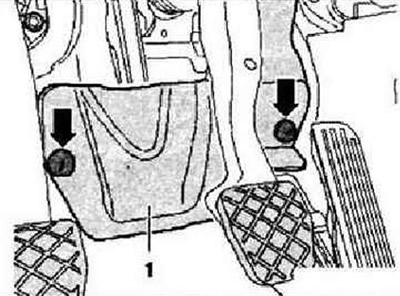

Disconnect battery. Remove footwell trim -1-, to do this unscrew nuts -arrows-.

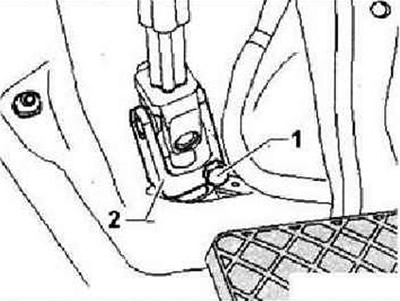

Loosen bolt -1- and remove universal joint -2- from steering gear shaft. Remove front wheels. Loosen the tie rod end nut a few turns, but do not remove it. To protect the thread, leave the nut threaded onto the top few threads of the pin.

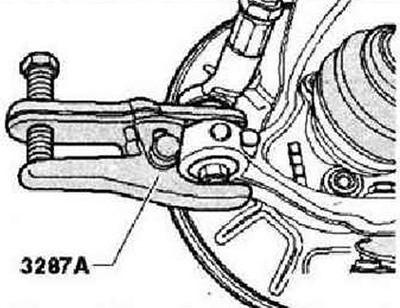

Using ball joint extractor -3287A-, press tie rod end out of steering knuckle. Now you can unscrew the nut. Remove the bottom soundproof casing. Disconnect from the stabilizer of its rack.

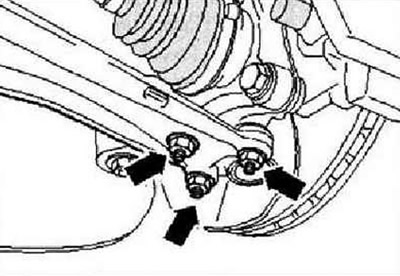

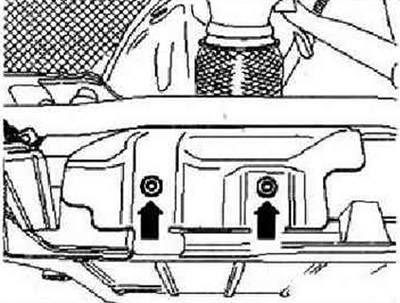

Remove nuts -arrows-.

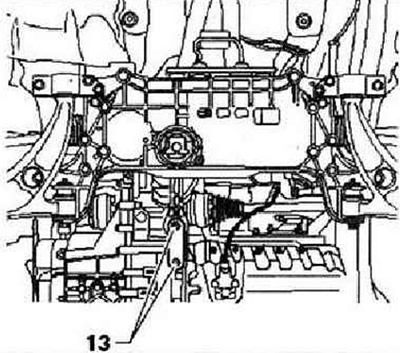

Disconnect the lower power unit support from the gearbox. To do this, unscrew bolts -13-.

Detach brackets for exhaust system -arrows- from subframe.

Front wheel drive vehicles

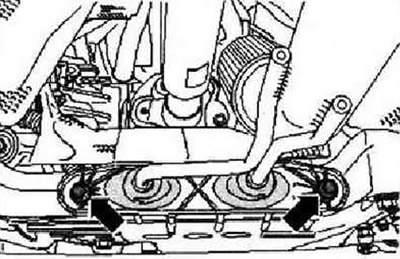

Remove bolts for heat shield -arrows-. Remove the heat shield from the subframe.

All

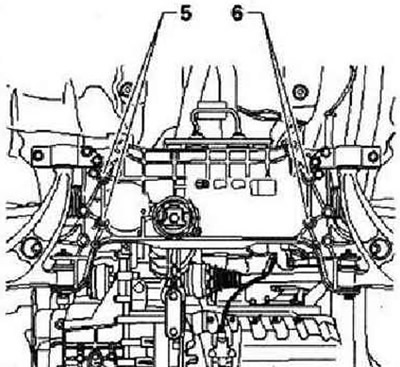

Remove steering gear mounting bolts -5- and -6-.

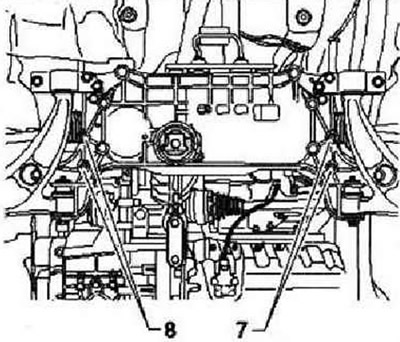

Remove stabilizer bolts -7- and -8-. Fix the position of the subframe. Disconnect the extended service interval counter connector on the oil pan.

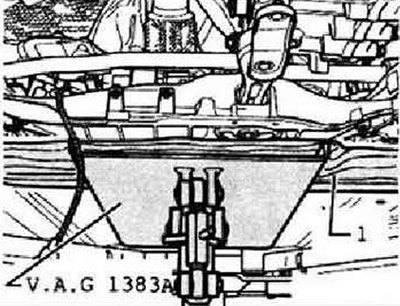

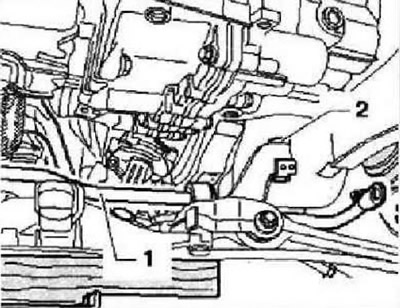

Position engine and gearbox jack -VAG 1383 A- under subframe. Place something between the jack -VAG 1383 A- and the subframe, eg a piece of wood -1-.

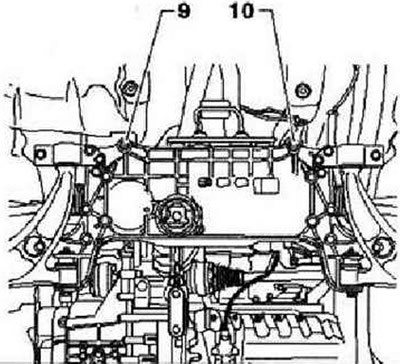

Remove bolts -9- and -10- and lower subframe slightly. Make sure that the electrical cables will not be damaged.

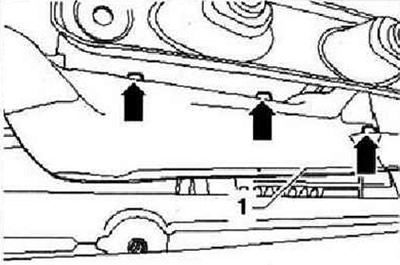

Remove heat shield -1- located above steering gear. Remove bolts -arrows-.

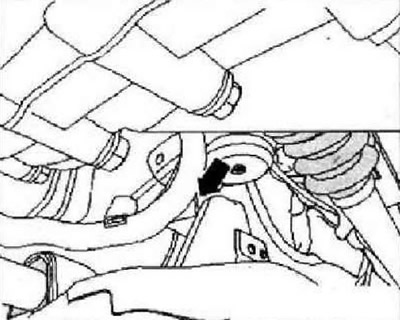

Unscrew wiring harness guide from subframe -arrow-. Remove all other clips securing the wiring harness to the steering gear.

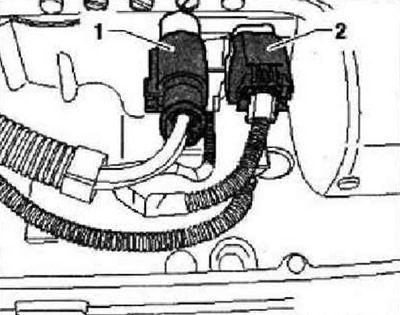

Disconnect connectors -1- and -2- from steering box. Carefully lower subframe using engine and gearbox jack -VAG 1363 A-.

Slightly turn the stabilizer to remove it forward and downward, passing it over the subframe -2-. Remove the steering gear from the subframe and lower it down.

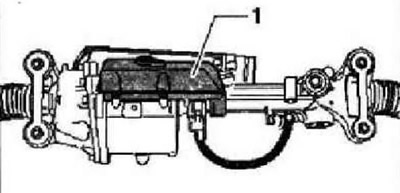

Lay the steering gear as shown in the figure. This will help avoid damage to the control unit -1-.

Installation

Installation is carried out in the reverse order.

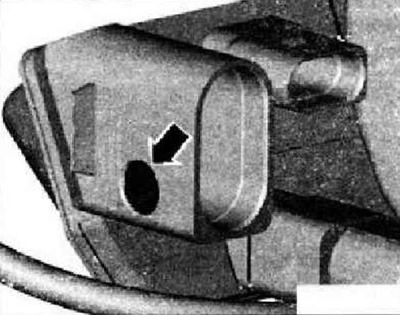

Check the condition of the white membrane -arrow-, it must be clean and intact. If necessary, carefully clean the membrane.

Instruction: If the membrane is damaged, the steering gear must be replaced.

Connect connectors -1- and -2-, you should hear a click when they lock. The threaded bushings of the steering mechanism must fit into the holes in the subframe.

Instructions: Before installing the steering gear, apply a lubricant, such as liquid soap, to the seal of the steering gear hole. After aligning the steering gear shaft and the steering shaft universal joint, it is necessary to check the evenness of the fit of the steering gear seal to the mounting plate (there should be no folds) and proper sealing of the opening in the bulkhead of the engine compartment. Non-adjacent installation will result in water leakage and/or noise. The sealing surface must be clean.

Before screwing in the subframe mounting bolts, install the steering gear on the subframe and insert the steering gear and stabilizer mounting bolts. Install the lower soundproof casing. Install the cardan joint on the steering gear shaft and tighten the mounting bolt. Connect the battery terminal. Carry out basic setting of steering angle sender -G85- using tester -VAS 5051-. After installation, it is necessary to make a test drive to check the position of the steering wheel. If the steering wheel is not level, and also after installing a new steering mechanism, it is necessary to adjust the wheel alignment angles. Adjust wheel alignment. After installing a new steering box, the power steering control unit -J5Q0- must be adapted using tester -VAS 5051-. Carry out basic setting of power steering control unit -J500-.

Note: If the vehicle is equipped with parking aid 2, the power steering control unit -J500- must be recoded.

Tightening torques

| Support bracket for body. Use only new bolts | 70 Nm and tighten by 180° |

| Stabilizer for subframe. Use only new bolts | 20 Nm and tighten by 90° |

| Stand stabilizer. Use only new nuts, hold the ball joint pin on the inner polyhedron | 65 Nm |

| Ball joint to triangular lever. Use only new nuts | 60 Nm |

| Heat shield to subframe, M6 screw is self-tapping | 6 Nm |

| Steering gear to subframe. Use only new bolts | 50 Nm and tighten by 90° |

| Cardan joint to the steering shaft. Use only new bolt | 30 Nm |

| Shielding shield to the steering gear, M6 screw is self-tapping | 6 Nm |

| Tie rod end to steering knuckle. Use only new nuts | 50 Nm |

The moments of an inhaling of bolts of fastenings of a subframe to a body

| M12x1.5x90. Use only new bolts | 70 Nm and tighten by 180° |

| M12x1.5x100. Use only new bolts | 70 Nm and tighten by 130° |

| M12x1.5x110. Use only new bolts | 70 Nm and tighten by 90° |

Tightening torques for the bolts of the lower support of the power unit to the gearbox

| M10x35. Use only new bolt | 50 Nm and tighten by 90° |

| M10x75. Use only new bolt | 50 Nm and tighten by 90° |

| M12x1.5x85. Use only new bolt | 60 Nm and tighten by 90° |

Visitor comments