Note: Toothed belt adjustment is only carried out when the engine is cold, as tensioner adjustment position varies with temperature.

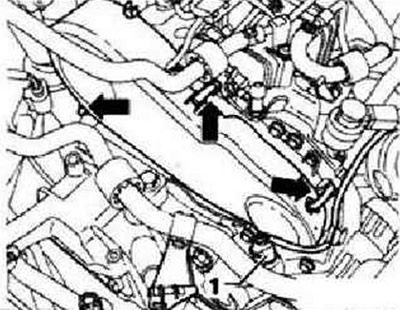

Remove engine cover. Remove fuel filter and additional fuel pump -V393-. Disconnect connector from radiator outlet coolant temperature sender -G83-, unfasten clips -arrows- and remove toothed belt guard. Remove the front right wheel arch liner. Remove poly V-belt. Remove vibration damper.

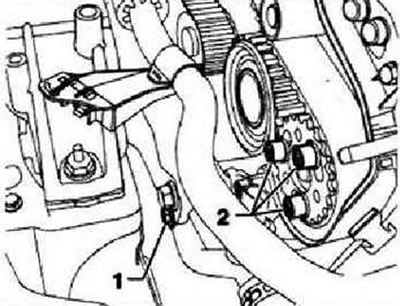

Remove lower and middle toothed belt guards -arrows- and unscrew securing nut for coolant pipe -1-.

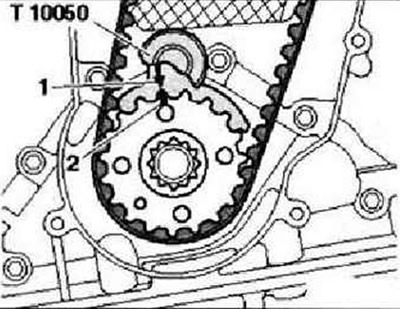

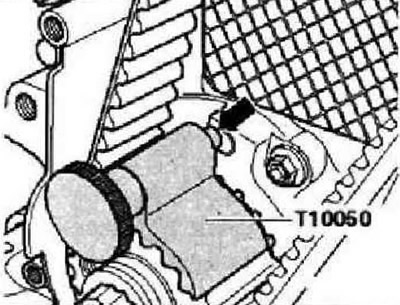

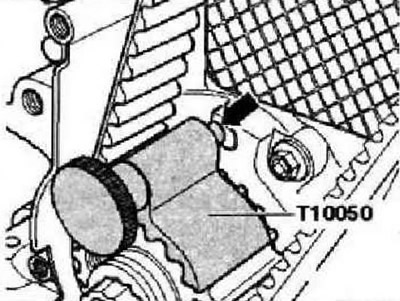

Move crankshaft to TDC position of cylinder 1 and lock crankshaft sprocket with tool -T10050-. To do this, insert the crankshaft stopper from the front of the toothed belt pulley into its teeth. The toothed segment of the camshaft pulley must face up («12 o'clock position»).

Note: Markings on crankshaft sprocket -2- and crankshaft lock -T10050- -1- must match. The pin of the crankshaft lock -T10050- must engage in the hole in the cover.

Mark the running direction of the toothed belt.

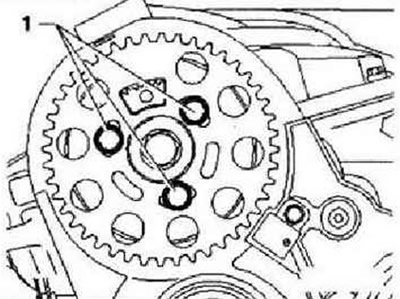

Loosen bolts -1- for camshaft pulley.

Loosen the bolt -1- of the cooling system pipe, and then the bolts of the injection pump pulley -2-.

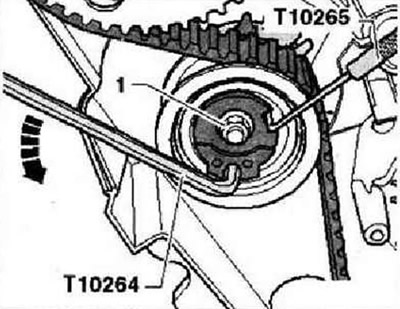

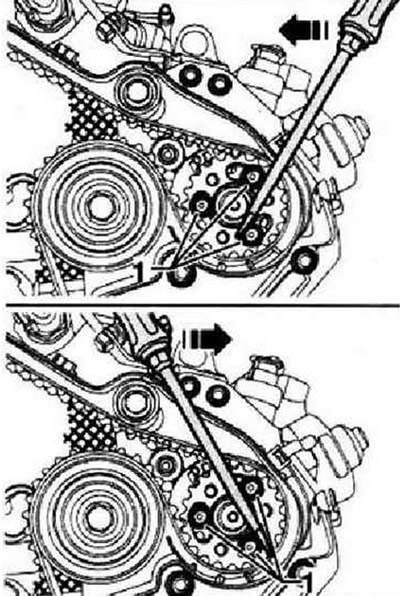

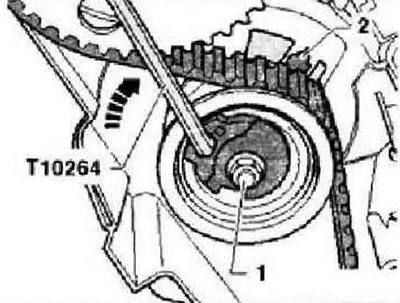

Loosen the tensioning roller nut -1- and turn the tensioning roller eccentric counterclockwise with the socket wrench -T10264- -arrow- until the tensioning roller can be locked with the locking pin -T10265-.

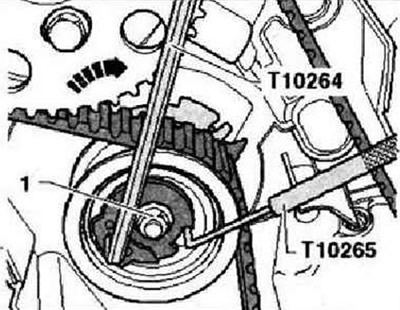

Now turn tensioning roller eccentric clockwise -arrow- as far as it will go and tighten securing nut -1- by hand. Remove the toothed belt first from the idler pulley and then from the remaining toothed pulleys.

Installation

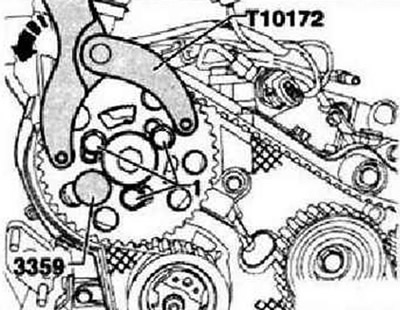

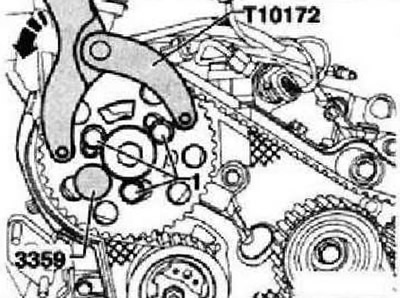

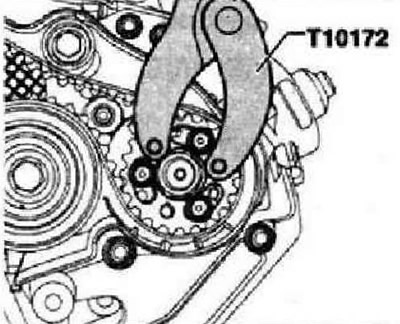

Note: Toothed belt adjustment is only carried out when the engine is cold, as tensioner adjustment position varies with temperature. If it is necessary to replace the tension roller, the support bracket must be removed. Replace the camshaft pulley and injection pump bolts. The tensioning roller must be retracted with the locking pin -T10265- and fixed in the rightmost position. The crankshaft is secured with the locking pin -T10050-. If necessary, turn camshaft hub using stop -T10172- and adapter -T10172/4- to a position where it can be locked. To do this, hand-tighten at least one securing bolt -1-.

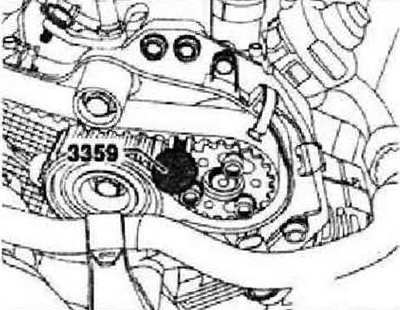

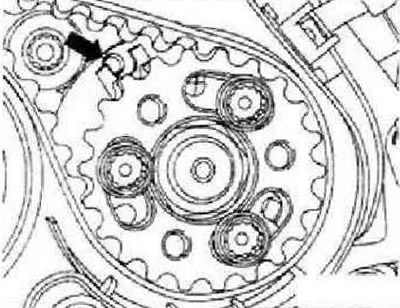

Secure camshaft hub with tool -3359-. To do this, insert the latch into the hole in the cylinder head through the free groove of the camshaft pulley. Loosen hand-tight bolts.

Instruction. If necessary, turn the injection pump hub with a screwdriver to a position where it can be locked (the screwdriver should be supported on the bolt heads, as shown in the figure).

Installing the injection pump hub in the correct position

Lock hub of high pressure pump with locking pin -3359-. To do this, insert the lock into the hole located on the side of the toothed pulley. Turn the camshaft pulley and the injection pump pulley in concentric grooves in a clockwise direction until it stops. Install the toothed belt on the crankshaft pulley, idler pulley, camshaft pulley, coolant pump pulley and on the injection pump pulley. Lastly, install the belt on the guide pulley, Loosen the nut securing the tensioning pulley and remove the retainer -T10265-.

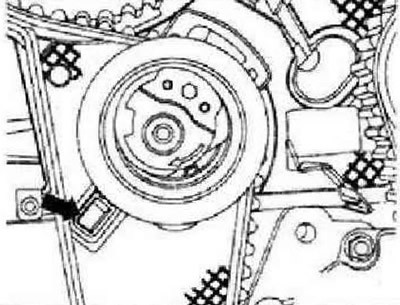

Instruction: Ensure correct position of tensioning roller in rear toothed belt guard -arrow-.

Carefully turn the eccentric of the tensioning roller clockwise with the angle screwdriver -T10264- until the pointer -2- is slightly above the center of the hole in the base (corrected when prestressing). The fastening nut -1- must not rotate. While holding the tensioning roller in this position, tighten the fixing nut as follows: 20 Nm and turn it further by 45°.

Position stop -T10172- as shown in illustration. Press stop -T10172- in direction of arrow and apply pressure to camshaft pulley. Tighten camshaft pulley bolts -1- and injection pump pulley bolts in this position, first by hand, then to 20 Nm. Remove retainers -3359- and retainer for crankshaft pulley -T10050-. Turn the crankshaft two turns in the direction of engine rotation and install it, slightly under TDC of the first cylinder. Reinstall tool -T10050- on crankshaft sprocket.

Now turn the crankshaft in the direction of engine rotation until the pin of the crankshaft stop -arrow- engages in the rotational movement in the sealing flange.

Instructions: Further verification is reduced to the simultaneous installation of the camshaft and crankshaft clamps. Re-fixation of the injection pump hub is hardly possible. A slight misalignment of the holes -arrow- does not affect the operation of the engine.

Check whether the camshaft hub can be secured with the pin -3359-, whether the roller pointer is between the center of the hole in the base and a position 5 mm to the right of the hole in the base. If the camshaft hub cannot be secured: Pull the crankshaft lock -T10050- slightly towards you until its pin comes out of the hole in the cover. Turn the crankshaft against the working direction of rotation so that the piston of the first cylinder is in a position slightly before TDC. Then slowly turn the crankshaft in the working direction until the camshaft hub can be locked. After fixing, loosen the screws securing the camshaft pulley.

If the pin of the crankshaft lock -T10050- is located to the left of the hole in the cover

Turn the crankshaft in the working direction so that the crankshaft lock pin enters the hole in the cover during rotation. Tighten the camshaft sprocket bolts first by hand and then to 20 Nm.

If the pin of the crankshaft lock -T10050- is located to the right of the hole in the cover

Again slightly turn the crankshaft against the working direction «growth. Now turn the crankshaft in the direction of engine rotation until the pin of the crankshaft lock moves out of the rotator into the sealing flange. Tighten the camshaft sprocket bolts first by hand and then to 20 Nm.

Continued description of works

Remove retainer -3359- for camshaft pulley and retainer -T10050- for crankshaft pulley. Turn the crankshaft two turns in the direction of engine rotation and install it, slightly under TDC of the first cylinder. Re-check the possibility of fixing the crankshaft. If it is possible to fix the camshaft hub, tighten the fixing screws as follows. Camshaft pulley: turn 45°further. Hold pulley with stop -T10172- and adapters -T10172/4-.

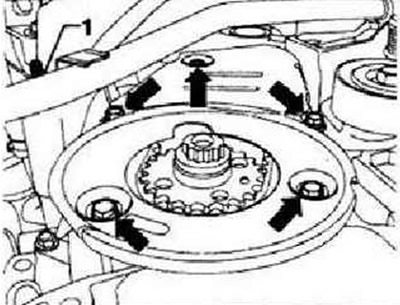

Injection pump pulley: tighten by 90°. Hold pulley with stop -T10172- and adapters -T10172/8-. Install the lower and middle toothed belt guard. Install vibration damper/belt pulley: tightening torque: 10 Nm + turn 90°further.

Install poly V-belt. Install the top toothed belt guard. Further installation is carried out in the reverse order of removal. In doing so, observe the following. Make sure fuel hoses are properly secured. Do not confuse pressure and return lines (return line blue or with blue mark, pressure line white). Install wheel arch liner. Install sound absorbing tray.

Visitor comments