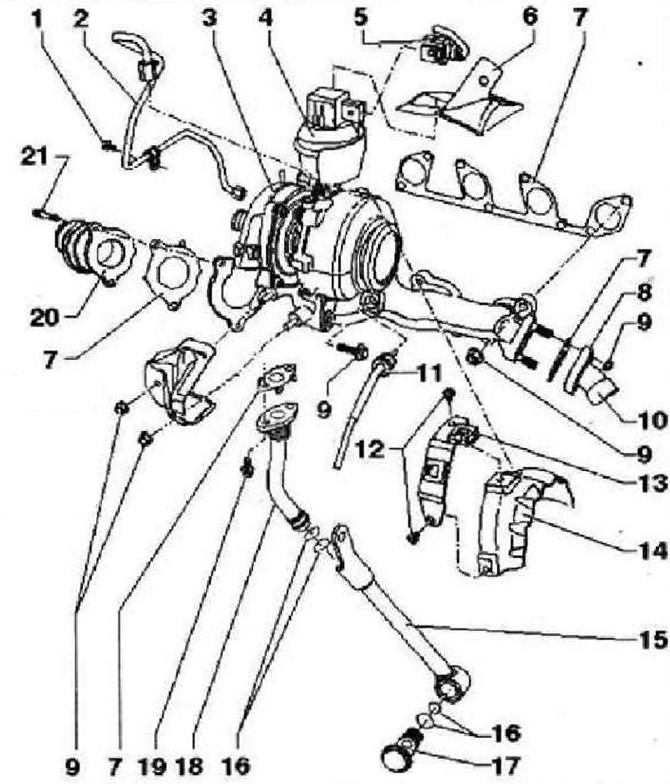

Instruction: All hoses are fixed on branch pipes. The boost system must be airtight. Replace self-locking nuts. Before connecting the oil pressure line, fill the turbocharger with engine oil through the oil pressure line connection. After installing the turbocharger, let the engine idle for about 1 minute without revving to ensure proper oil supply to the turbocharger.

- 1 - 10 Nm

- 2 - Pressure oil line, before installation check for blockages, before installation, fill oil into the turbocharger through the union of the pressure oil line

- 3 - Turbocharger, replace only complete with exhaust manifold and vacuum unit

- 4 - Vacuum actuator with charge pressure regulator position sender -G581 -

- 5 - Connector to charge pressure regulator position sender -G581-

- 6 - Heat shield, replace if damaged

- 7 - Gasket, replace

- 8 - Connecting pipe to the radiator of the exhaust gas recirculation system

- 9 - 20 Nm

- 10 - Bellows, do not kink or twist

- 11 - Exhaust gas temperature sender 1 -G235-, 45 Nm. Apply heat-resistant paste -G 052112 A3- to sensor thread, observe installation position

- 12 - 10 Nm

- 13 - Bracket for oil supply line

- 14 - Heat shield

- 15 - Support bracket between turbocharger and cylinder block

- 16 - O-ring, replace

- 17- Hollow bolt, 60 Nm, replace

- 18 - Oil return pipe

- 19 - 15 Nm

- 20 - Pulsation damper

- 21 - 10 Nm

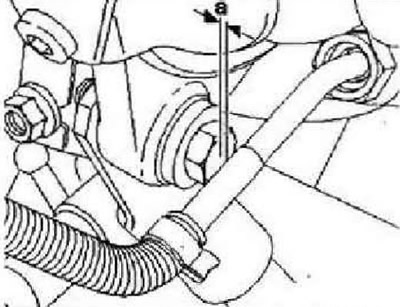

Mounting position of the exhaust gas temperature sensor with bent rods

Note: When installing an exhaust gas temperature sensor with a bent rod, be sure to maintain dimension -a- 3...5 mm up to the turbocharger support bolt.

Visitor comments