Instructions: Both spring clamps and crimp clamps can be used to fasten hoses. Crimp clamps should always be replaced with spring clamps. We recommend using spring clip pliers -VAS 6362- or pliers -VAS 6340- for installing spring clips.

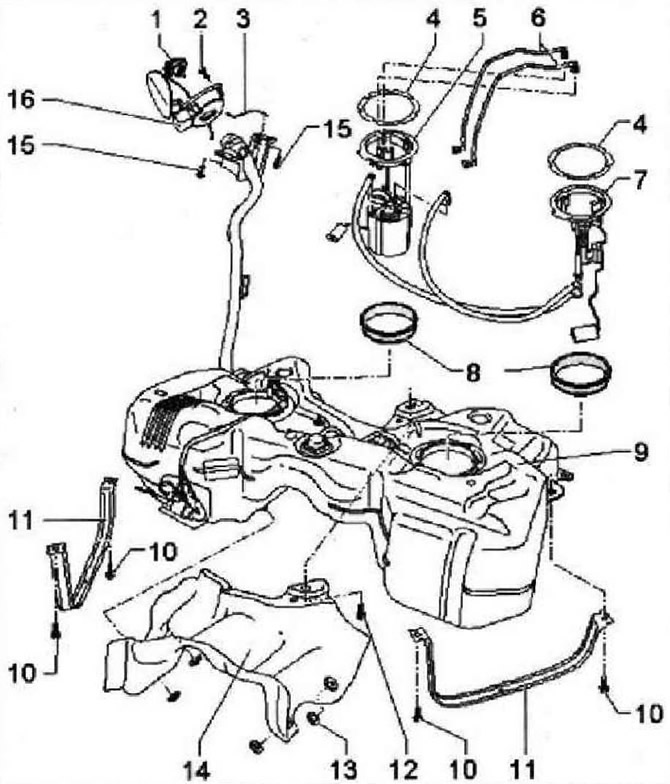

- 1 - Filler cap, replace if damaged

- 2 - Fixing screw

- 3 - Ground wire, check for secure fastening

- 4 - Retaining ring, 110 Nm, check secure fit, remove and install using wrench -T10202-

- 5 - Place the fuel priming pump -G6- in the correct position on the tank. With fuel gauge sender -G-, clean mesh if necessary

- 6 - Connecting pipes for pressure and return fuel lines, install in accordance with the color. Fastened to the side of the fuel tank, check the fastening

- 7 - Fuel level sender 2 -G169-

- 8 - O-ring, if damaged, replace, install dry in the opening of the fuel tank, when installing the flange, moisten with fuel

- 9 - Fuel tank

- 10 - 20 Nm and turn 90°further, replace. To fix the clamps for fastening the fuel tank, it is allowed to use only bolts with washers turning on them. When using other bolts, the clamps may warp when tightened

- 11 - Clamp, install in proper position

- 12 - 20 Nm and tighten by 90°, replace

- 13 - Clamping washer

- 14 - Heat shield

- 15 - 8 Nm and tighten by 90°, replace

- 16 - Filler hatch assembly with rubber sheath

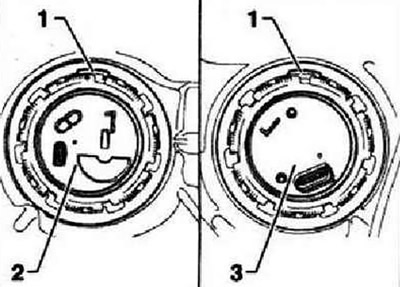

Mounting position of the fuel supply module flange and fuel level sensor 2-G169-

Fuel supply module -3-: tongue -1- points in direction of travel.

Fuel gauge sender 2 -G169- -2-: tongue -1- points in direction of travel.

Instructions: Ignore the arrows marked on the round nuts.

Visitor comments