ATTENTION: Instructions and rules for maintaining cleanliness must be observed before and during work. In order to prevent the operation of the high-pressure fuel pump in the dry friction mode and to quickly start the engine after replacing parts, it is imperative to perform the following work. When removing or replacing units and components of the fuel system located between the tank and the injection pump, it is necessary to remove air from the system by performing the basic setting "Checking the booster fuel pump". When removing or replacing the fuel pump, fuel lines or fuel filter, a basic setting must be carried out before starting the engine "Checking the booster fuel pump" 1 time. When removing or replacing the injection pump, a basic setting must be carried out before starting the engine "Checking the booster fuel pump" 3 times.

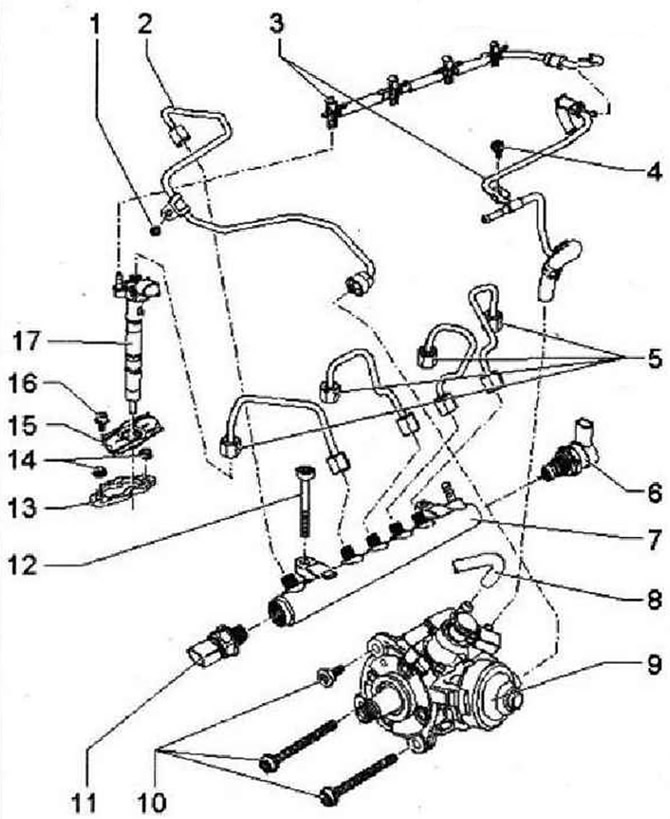

- 1 - 10 Nm

- 2 - High pressure line, 25 Nm, between injection pump and pressure accumulator (fuel rail)

- 3 - Fuel return lines with pressure reducing valve, note different design groups

- 4 - 10 Nm

- 5 - Injector lines, 25 Nm, between pressure accumulator (fuel rail) and injectors. High-pressure lines can be reused after the following checks: Check the sealing cone of the corresponding line for deformations and cracks. The hole must not be deformed, dirty or damaged. Lines that have corroded should not be used again, do not interchange, install stress-free

- 6 - Fuel pressure regulator -N276-, 80 Nm, check

- 7 - High pressure accumulator (fuel rail)

- 8 - Fuel supply line

- 9 - injection pump

- 10 - 20 Nm

- 11 - Fuel pressure sender -G247-, 100 Nm

- 12 - 22 Nm

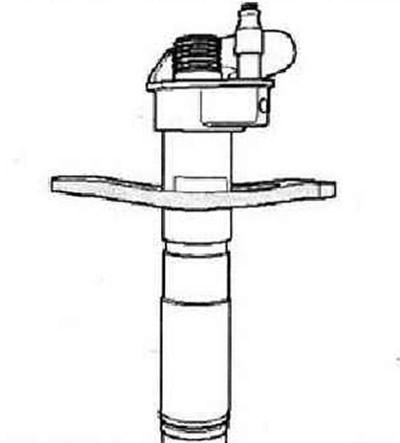

- 13 - Pressure plate, replace, observe installation position

- 14 - 10 Nm

- 15 - Injector cover

- 16 - 5 Nm

- 17 - Nozzle (piezo injector). The following components and gaskets or O-rings must be replaced each time they are removed and installed: "copper washer" "injector seat sealing ring", "o-ring of the circular section of the nozzle drain". When installing a new injector, the following parts and seals or O-rings must be replaced: "pressure plate", "copper washer", "nozzle seal ring", "injector return seal". Re-installed nozzles must be put exclusively in their original place (cylinder). Before reuse "high pressure injection lines" visually inspect the sealing cones for damage, e.g. transverse seizing, corrosion, replace if necessary

Mounting position of pressure plate

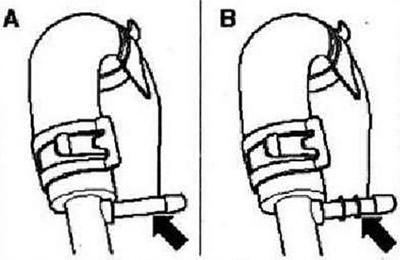

Miscellaneous fuel return lines

- -A-, without knurling: use a clamp to connect the oil bypass pipe

- -B-, knurled: DO NOT use a clamp to connect the oil bypass line

Visitor comments