Caution: When carrying out installation work, especially in the engine compartment due to its dense layout, the following rules must be observed. Pipelines of all kinds (fuel, hydraulic, absorber, coolant, coolant, brake fluid, vacuum) and electrical wires must be laid as they were originally laid. To avoid damage to hoses, pipes or wires, sufficient space must be provided when working on all moving or hot parts.

Interrogate the fault memory of all control units before removal. Disconnect the ground wire from the battery with the ignition off. Remove engine cover.

Remove air filter. Remove the battery and the battery holder frame. Remove wiper arms, Remove plenum box trim. Disconnect the left engine wiring harness connector from the engine control unit. Unlock entry of engine wiring harness -arrow- and remove upwards.

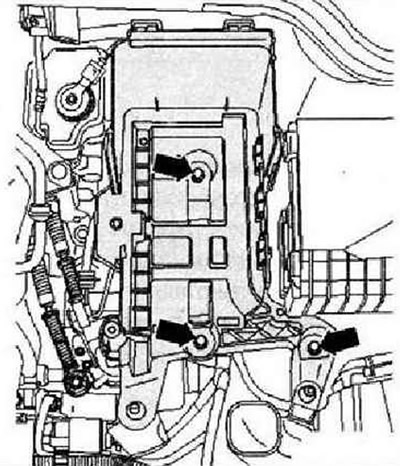

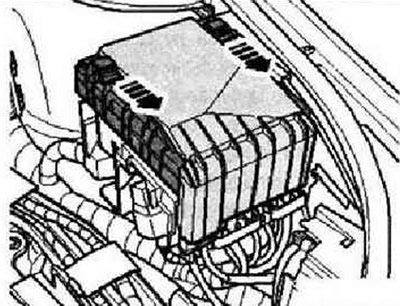

Remove the cover of the electronics box in the engine compartment; to do this, move the two locks in the -direction of the arrow-.

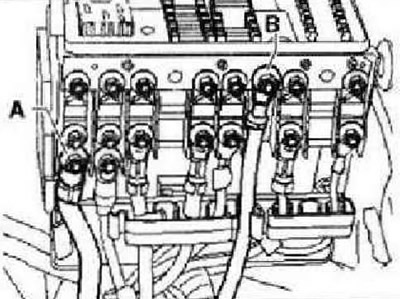

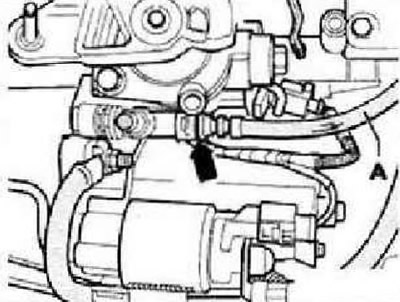

Disconnect the cable from the alternator -A- and the cable from the battery -B- at the fuse holder.

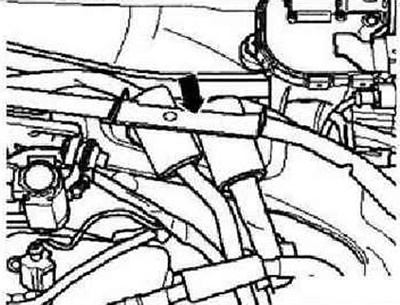

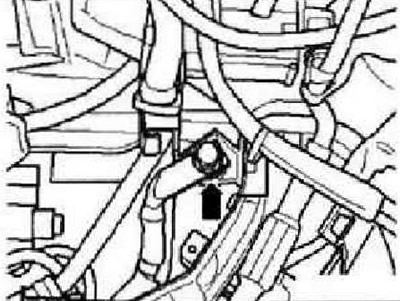

Unscrew earth cable from side member -arrow-.

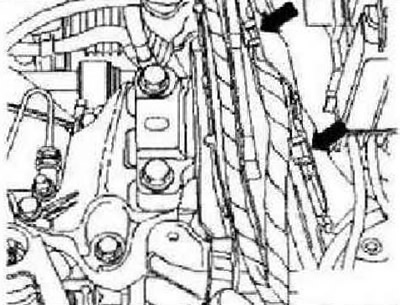

Open cable guide retainers on side member -arrows-.

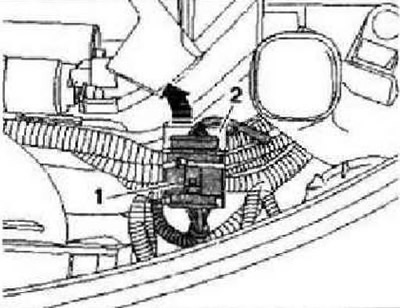

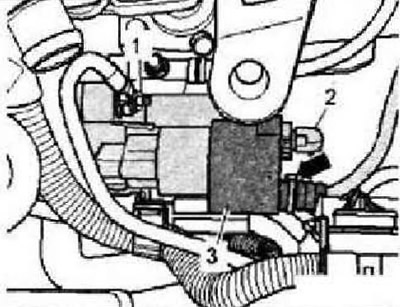

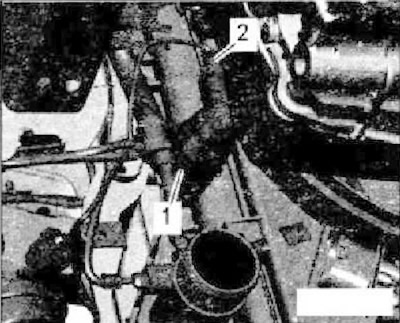

Unclip and unplug electrical connector -1-. Open the holder located under it -2 wiring. Remove the wiring harness to the engine control unit from the wiring holder and place it on the engine.

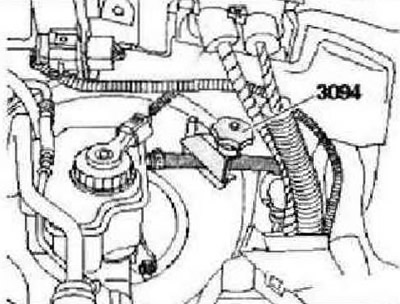

Remove the gearbox shift mechanism. Clamp hose to clutch master cylinder with clamp -3094-.

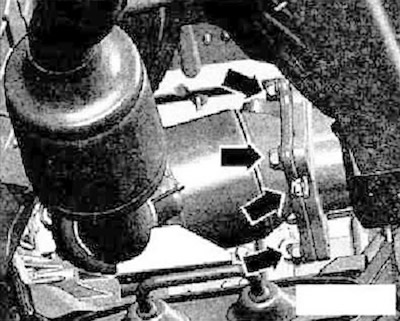

Pull out pipe clamp -arrow- as far as it will go.

Remove the pipeline from the fan/working cylinder and plug it.

Carefully. Do not press the clutch pedal again.

With automatic transmission

Remove selector cable from gearbox. Disconnect lines to transmission oil cooler from transmission.

With DSG

Remove the selector cable from the gearbox.

All

Disconnect electrical connector -2-.

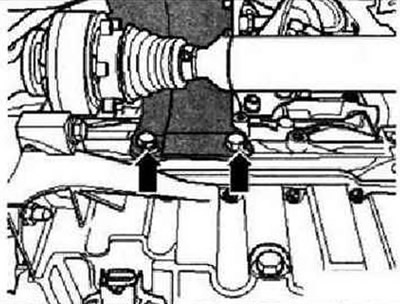

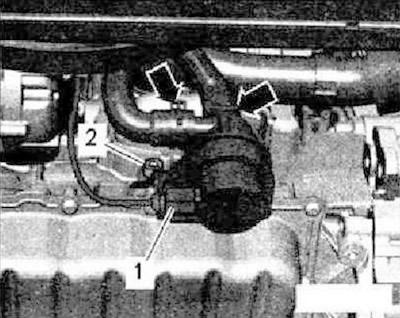

Unscrew upper securing bolts for air intake -arrows-.

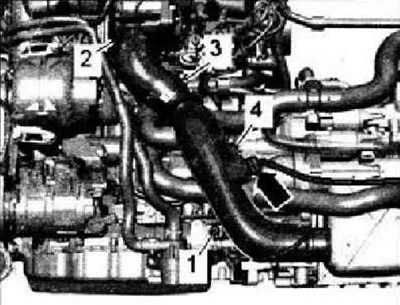

Detach hose clamp -2-. Remove bolt -4-. Unplug electrical connector -arrow- and move electrical cable clear.

WARNING: Risk of scalding from hot steam and hot coolant.

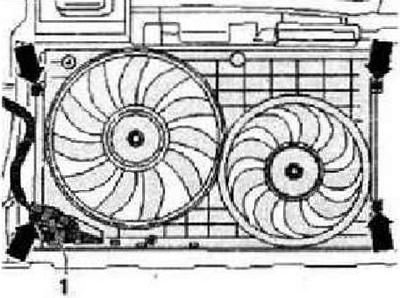

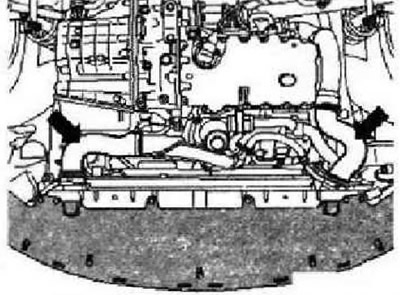

Open the coolant expansion tank cap. Remove soundproof screen. Remove front fender liner or front fender liner. Remove charge air hoses -arrows-.

Remove bolt -1- and remove air duct downwards. Unplug connector -1- and unscrew lower securing bolts -arrows- for air intake. Remove the air intake downwards. Unplug electrical connector -2- for radiator outlet coolant temperature sender -G83-.

Place drip tray -VAS 6208- under engine. Drain coolant.

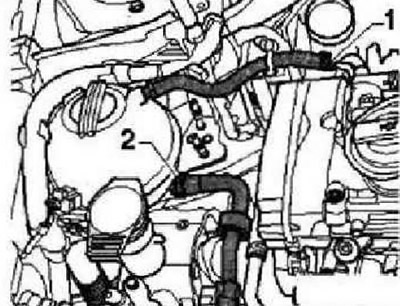

Detach coolant hoses -1 and 2-.

WARNING: The fuel pressure line is under pressure!

Disconnect the lines at the fuel transfer points.

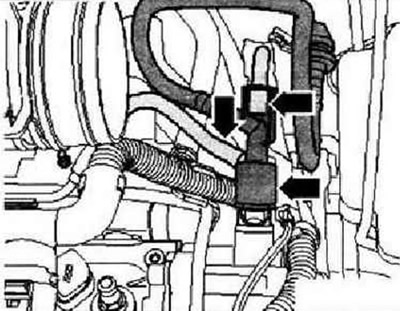

Disconnect the coolant hose from the radiator on the right and the coolant hose from the radiator on the left. Detach coolant hoses to heater heat exchanger -arrows-, to do this loosen retaining clip slightly.

Unscrew accessible nuts -arrows- from exhaust exhaust pipe to turbocharger from above.

Remove vacuum hoses -arrows-.

Front wheel drive vehicles

Unscrew heat shield for right drive shaft -arrows-.

All

Remove drive shafts. Remove the exhaust manifold downpipe with catalytic converter.

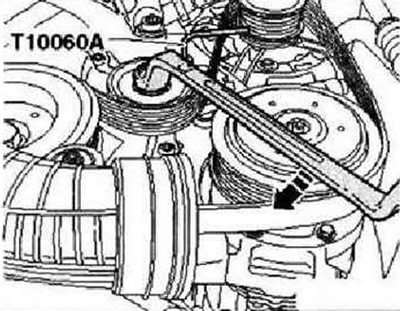

Carefully. Danger of delaying a previously used V-ribbed belt when changing its course. For re-installation, before removing the V-ribbed belt, mark the direction of its running with chalk or a felt-tip pen.

To loosen the poly V-belt, turn tensioner from below in -direction of arrow-. Secure belt tensioner with locking pin -T10060 A-. Remove poly V-belt.

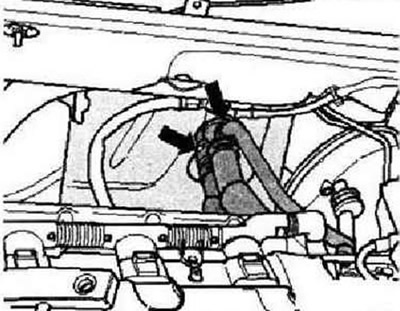

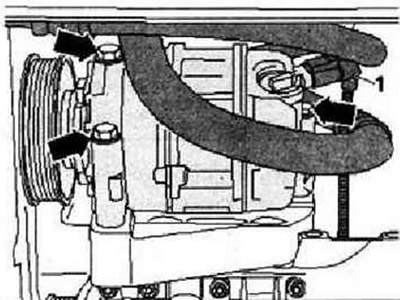

Unplug electrical connector -1- at air conditioner compressor regulating valve -N280-.

WARNING: Risk of injury from coolant. It is forbidden to depressurize the refrigerant circuit of the air conditioner.

Remove bolts -arrows- for air conditioner compressor -1-.

Caution: Risk of damage to refrigerant lines and hoses. Do not kink, kink or bend refrigerant lines and hoses.

Tie up air conditioner compressor with connected hoses to side member.

All

Remove bolt -2- on bracket for coolant overrun pump -V51-.

Note: Coolant overrun pump -V51- remains in installation position.

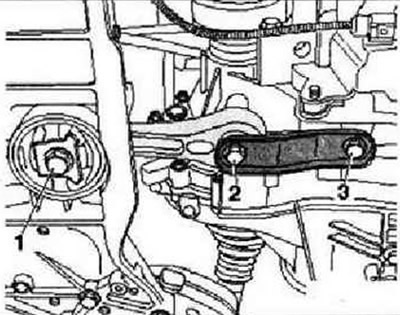

Remove bolts -1...3- and remove pendulum support.

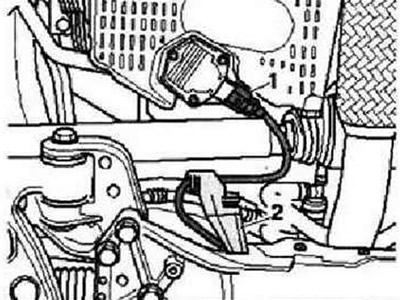

If fitted, unplug electrical connector -1- for temperature and oil level sender -G266- and remove holder -2- from subframe. Disconnect all other wires from the engine and gearbox that need to be disconnected and lay them aside. Disconnect all connecting, vacuum, inlet and coolant supply and return hoses from the engine.

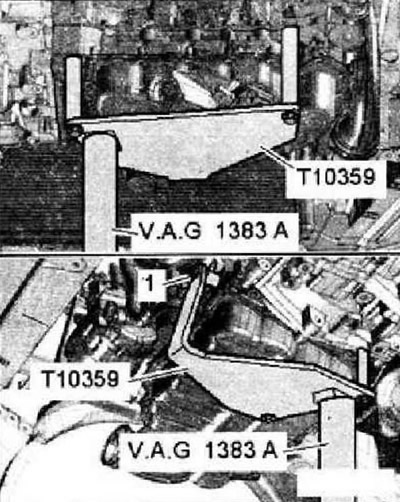

Screw engine bracket -T10359- with bolt -1- to cylinder block to 20 Nm.

Note: The threaded hole for the bolt -1- is for screwing in the coolant overrun pump -V51-.

Position jack -VAG 1383 A- under engine bracket -T10359-. Raise the engine and gearbox slightly.

Instructions: Use the VAS 5035 stepladder to unscrew the bolts of the suspension of the power unit,

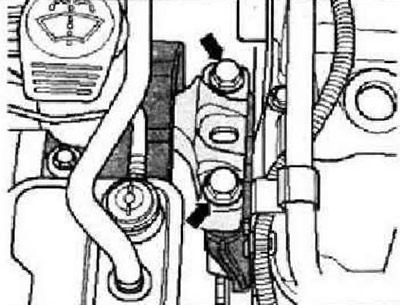

Unscrew the bolts -arrows- for the suspension of the power unit on the engine,

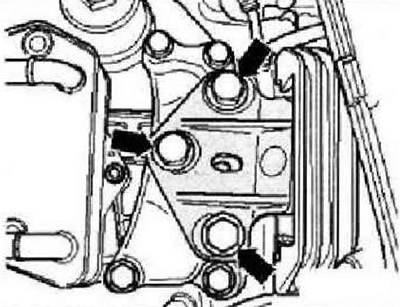

Unscrew bolts -arrows- for power unit mounting on gearbox.

Instruction: Check that all hoses and wires between the engine, body and gearbox are disconnected, lower the engine with gearbox carefully to avoid damage.

Dual clutch transmission

Pay attention to the automatic transmission selector cable.

All

Pull the power unit forward as far as possible and slowly lower it down. For assembly work, the engine must be secured to the engine jack -VAS6095-.

Visitor comments