Instruction: If during the repair in the engine metal chips were found in large quantities, this may be due to a malfunction of the connecting rod bearing. To avoid subsequent damage, the following must be done after repairs: Thoroughly clean the lubrication channels, replace the oil filter. The oil level must not exceed the max mark - risk of catalytic converter damage!

The amount of oil to be filled in with an oil filter is 4.0 liters.

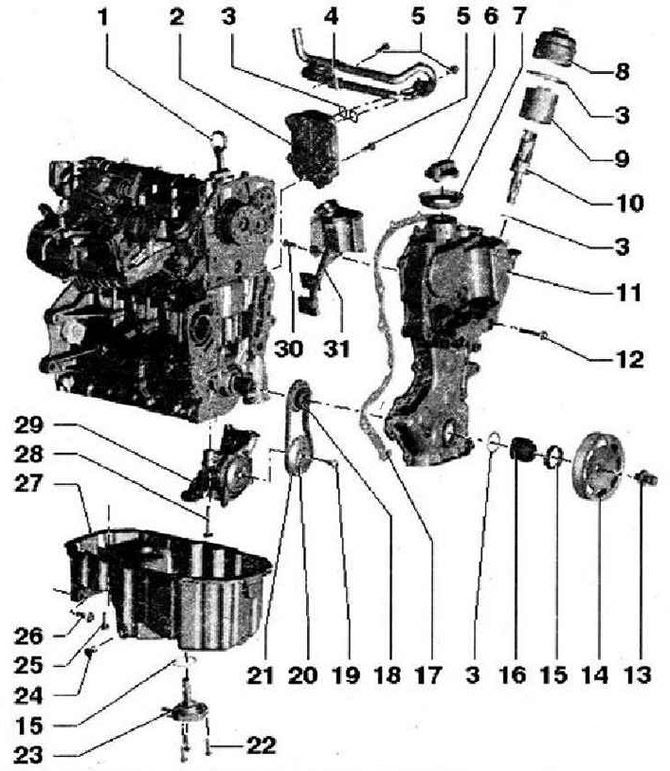

- 1 - Oil dipstick. The oil level must not exceed the max mark!

- 2 - Oil cooler

- 3 - O-ring, replace

- 4 - Pipe of the cooling system for the oil cooler, tightening torque of the bracket to the engine crankcase: 20 Nm

- 5 - 8 Nm

- 6 - Cover, replace gasket if damaged

- 7 - Shaft seal, replace if damaged

- 8 - Oil filter housing cover, 25 Nm. With quick shut-off valve, opening pressure: 2.50 barg. With oil return shut-off valve

- 9 - Filter insert

- 10 - Valve

- 11 - Timing mechanism cover. Install additionally using sealant D 176 501 A1. To facilitate installation, screw two spacer bolts M6x80 into the camshaft housing and cylinder block. To facilitate the installation of the timing cover, screw the oil pan with two bolts

- 12 - 10 Nm

- 13 - Fixing screw. There must be no oil on the contact surface of the bolt head and grease should be inserted after lubricating with oil (carving), secure the belt pulley against twisting with counterhold 3415. The tightening angle can be measured with a standard measuring disc, e.g. Hazet 6690

- 14 - Belt pulley. The mating surfaces must be free of oil and grease, secure the belt pulley against rotation using counterhold -3415-

- 15 - Shaft seal, replace

- 16 - Bearing sleeve. The mating surfaces of the support sleeve must be free of oil and grease

- 17 - Seal, replace if damaged

- 18 - Asterisk to drive the oil pump

- 19 - 20 Nm and tighten by 90°, replace

- 20 - Oil pump sprocket, secure with locking key -T10172-

- 21 - Oil pump drive chain, mark direction of travel before removing (installation position)

- 22 - 10 Nm

- 23 - Engine oil level and temperature sender -G266-, replace if damaged, check

- 24 - Oil drain plug, 30 Nm. With fixed lip seal, replace

- 25 - 13 Nm. Loosen and tighten bolts on flywheel side only using tool -T10058-

- 26 - 45 Nm

- 27 - Oil pan, clean seating surfaces before installation, install with silicone sealant D 176 600 A1

- 28 - 25 Nm

- 29 - Oil pump, replace only as an assembly

- 30 - 5 Nm

- 31 - Oil separator

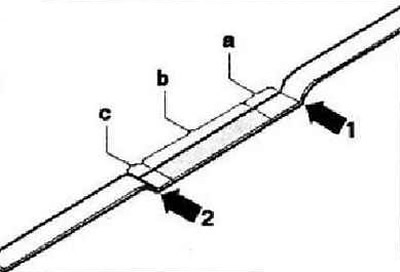

Oil dipstick marks

- 1 - mark max

- 2 - mark min

- a - if the oil level is above the corrugated field and below the max mark - do not add oil!

- b - actual level in the shaded field: engine oil can be topped up c - if the oil level is between the min mark and the grooved field: top up with max. 0.5 l of oil!

Visitor comments