Caution: When carrying out installation work, especially in the engine compartment due to its dense layout, the following rules must be observed. Pipelines of all kinds (fuel, hydraulic, absorber, coolant, coolant, brake fluid, vacuum) and electrical wires must be laid as they were originally laid. To avoid damage to hoses, pipes or wires, it is necessary to provide enough space when working with everything and moving or hot parts.

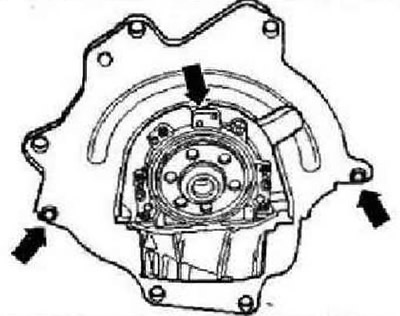

Check clutch release bearing for wear, replace if necessary. Coat clutch release bearing, guide sleeve and input shaft splines with a thin coat of lubricant for clutch disc teeth -G 000 100-. Check for the presence of centering bushings that determine the relative position of the engine and gearbox. If bushings are missing, they must be installed in the cylinder block. Position intermediate plate on dowel sleeves of engine flange -arrows-.

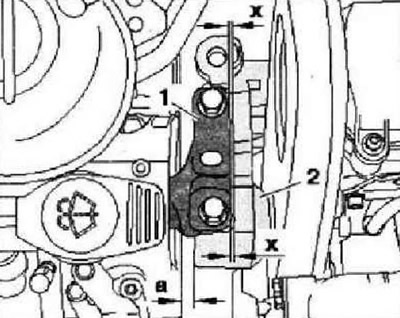

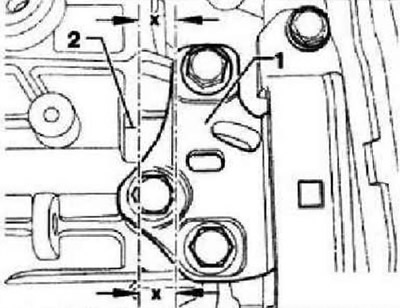

Align the engine mount as follows. There must be a distance -a- of at least 10 mm between the engine support and the right side member. The cast edge in the engine support -2- must be parallel to the bracket.

On gearbox side, note parallelism of bracket -1- and gearbox bracket -2-.

Install the exhaust pipe.

All wheel drive vehicles

Install gearbox bracket for bevel box.

Instructions: First tighten the fixing nuts by hand.

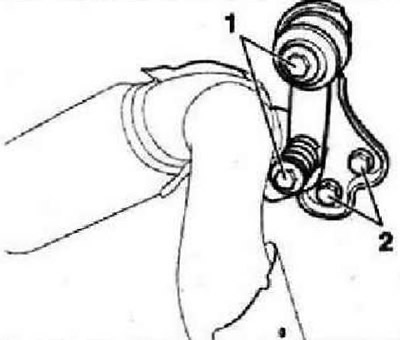

Position exhaust pipe support and tighten securing bolts -1- and -2- to 25 Nm.

Install the subframe. Install driveshaft.

Continuation for all cars

Install drive shafts. Install the gearshift drive. Connect hose -1- for hydraulic clutch slave cylinder. Install pendulum support. Install the air conditioner compressor. Install poly V-belt. Electrical connections and wiring. Drink coolant. Install the air filter. Install the battery and battery mounting pad. Connect the battery. Press engine cover at points -1- in -direction of arrow- downwards until it snaps into place at these points. Connect tester -VAS 5051B-. Delete the adaptation parameters from the memory and adapt the engine control unit to the throttle valve unit. Carry out system diagnostics. Complete the diagnosis of the vehicle's systems so that errors that may have been registered during installation are automatically cleared from the fault memory.

Tightening torques

| M6 | 10 Nm |

| M8 | 20 Nm |

| M10 | 45 Nm |

| M12 | 60 Nm |

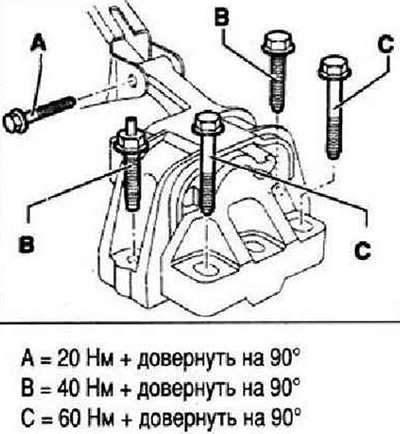

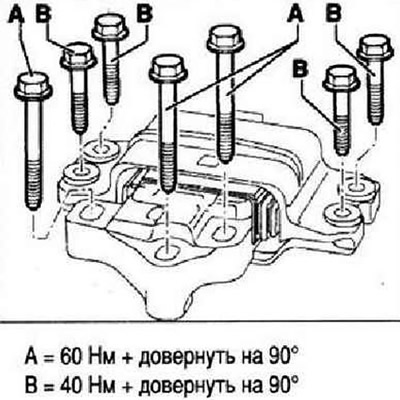

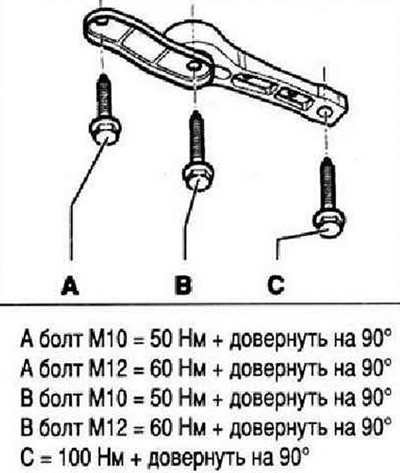

Power unit support

Note: The assembly support bolts are malleable bolts and must be replaced.

Engine support

Gearbox support

pendulum support

Visitor comments