Instructions: Work on the cardan shaft should, if possible, be carried out on a two-bearing platform lift. Before removal, mark the location of all mating parts relative to each other. Assembly is carried out according to the marks made, ensuring the initial location of the parts relative to each other. This will eliminate the possibility of damage to the bearings and the occurrence of noise caused by the resulting imbalance. Do not bend the cardan shaft; stack and transport it only in a straight line. When removing the cardan shaft, do not allow it "sagging" always support the shaft under its own weight. Disconnect and connect the PTO shaft to the flange always horizontally.

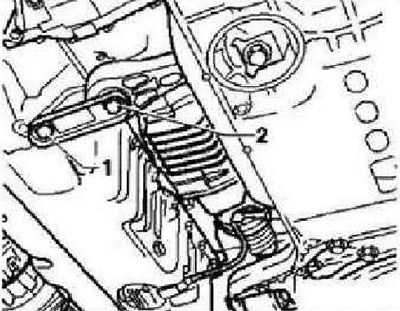

Remove soundproofing. Unscrew bolts -1- and -2- for lower power unit support.

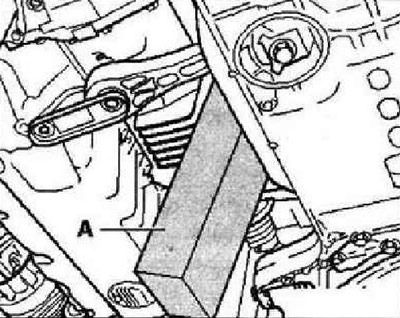

wring out «engine and gearbox» hand forward and fix them in this position with a suitable piece of wood -A-. Support front section of exhaust system with jack -VAG 1383 A-.

Loosen clamps -arrows- and remove rear section of exhaust system. Remove the tunnel cross member.

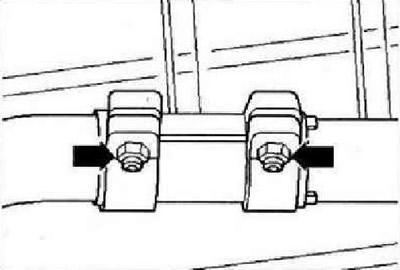

Loosen bolts -arrows- for intermediate bearing two turns. Loosen propshaft front and rear, but do not unscrew yet.

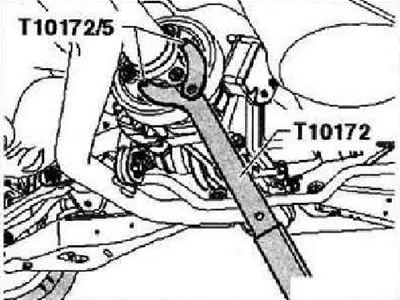

To disconnect and tighten the cardan shaft, carry out a hold on the rear final drive.

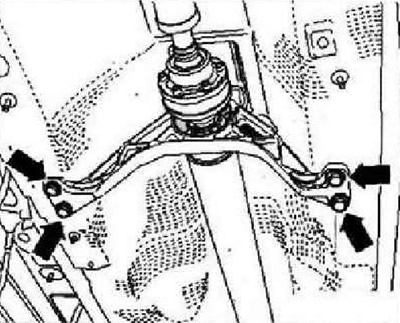

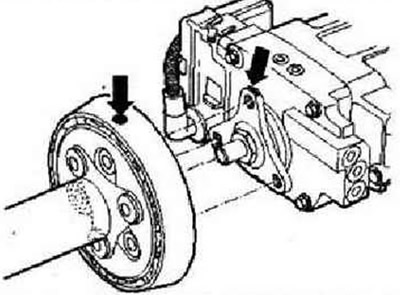

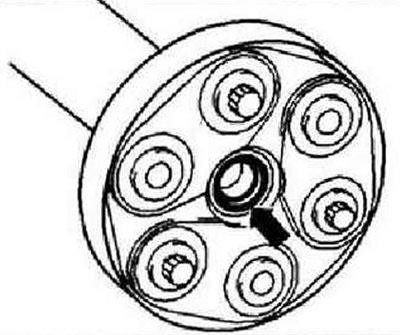

To avoid noise later due to imbalance. If there are no marks -arrows-, mark the position of the propshaft in relation to the flange on the final drive. Also mark the position of the propshaft in relation to the flange on the bevel gear. Unscrew propshaft from rear final drive and place on jack -VAG 1383 A-

When pulling out and connecting the propshaft, always take care not to damage the sleeve -arrow-.

Unscrew cardan shaft from bevel gear.

CAUTION: In order not to damage the protective cover on the intermediate bearing, remove and install and store the cardan shaft as straight as possible.

Unscrew the intermediate support and pull the propshaft downwards as straight as possible.

Installation is carried out in the reverse order. All components whose mutual position relative to each other has been marked must be installed in their original position. Tighten driveshaft. Attach the lower support of the power unit «new» bolts. Install exhaust system. Install soundproof cover. Install the tunnel cross member.

Visitor comments