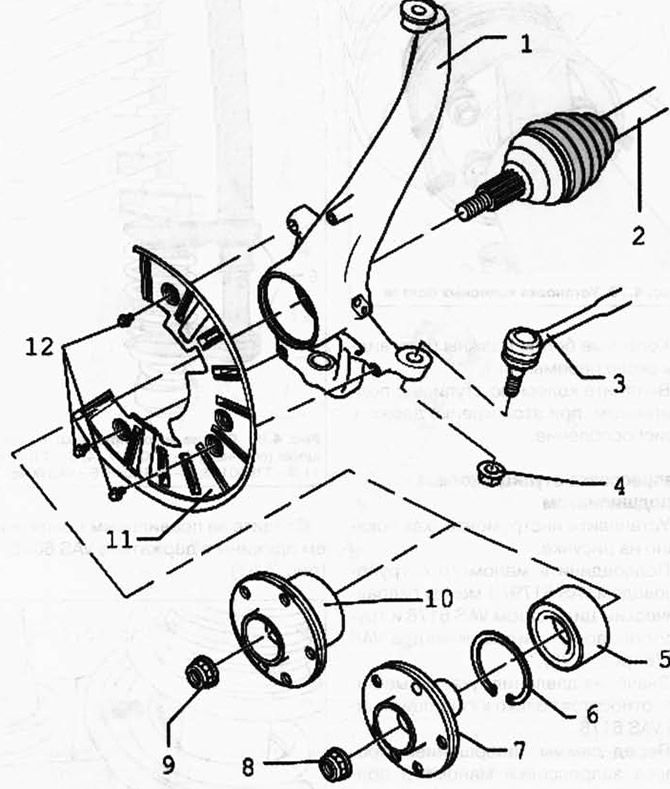

Pic. 4.75. Support components:

1 - wheel bearing housing; 2 - drive shaft; 3 - transverse lever; 4 - self-locking nut; 5 - wheel hub bearing; 6 - retaining ring; 7 - wheel hub; 8 - self-locking nut; 9 - self-locking nut; 10 - wheel hub with bearing; 11 - shield; 12 - a bolt with a six-sided head.

Removing wheel hub with bearing

Remove the drive shaft first. Bolt the upper suspension arm firmly to the wheel bearing housing.

Fix the brake disc with the wheel bolt (pic. 4.76).

Remove the caliper and hang on a wire to the body.

Remove the brake disc and shield.

Unclip the speed sensor wire.

Remove the ABS speed sensor.

Screw the grips Т10205/12 with wheel bolts to the wheel hub.

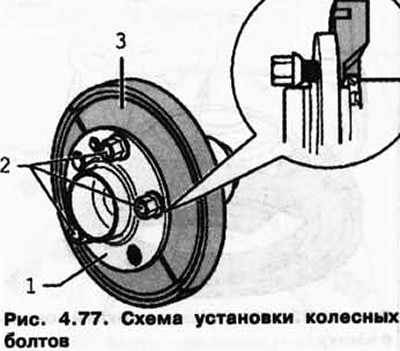

The wheel bolts 2 must not protrude on the rear side of the grippers (pic. 4.77).

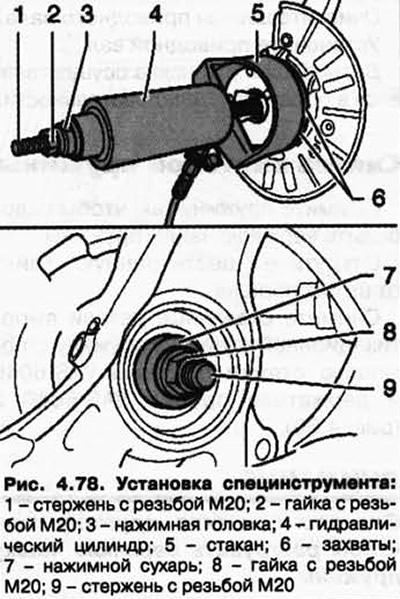

Install the tools as shown in Figure 4.78.

Install the wheel bolts as shown in Figure 4.79.

The wheel bolts must be visible near lintel 1.

Pull out the wheel hub with bearing while holding the fixture firmly.

Pressing in wheel hub with bearing

Install the tools as shown in the picture.

Connect pressure gauge with pipe VAS 6179/1 between hydraulic cylinder VAS 6178 and hydraulic cylinder pipe VAS 6178 (pic. 4.78).

The pressure values given below refer only to the hydraulic cylinder VAS 6178.

Just before the completion of the pressing process, the pressure gauge should show a pressure in the range from 90 to 140 bar.

The maximum pressing pressure must not exceed 310 bar.

Press the wheel hub in until it stops.

Clean the drive shaft splines.

Install the drive shaft.

Further installation is carried out in the reverse order.

Visitor comments