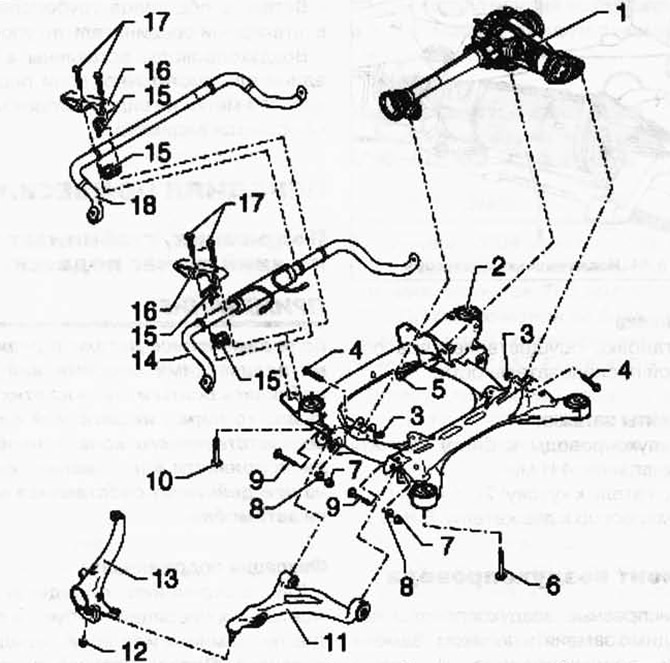

Pic. 4.46. Assembly assembly diagram - subframe, stabilizer, lower suspension arm:

1 - front main gear; 2 - subframe; 3 - self-locking nut; 4 - a bolt with a six-sided head; 5 - a bolt with a six-sided head; 6 - a bolt with a six-sided head; 7 - self-locking nut; 8 - eccentric washer; 9 - eccentric bolt; 10 - a bolt with a six-sided head; 11 - lower suspension arm; 12 - self-locking nut; 13 - wheel bearing housing; 14 - switchable stabilizer; 15 - stabilizer bearing; 16 - bracket; 17 - a bolt with a six-sided head; 18 - stabilizer.

NOTE: If parts with rubber-metal supports have been replaced or bolts and nuts on these parts have been loosened, then before tightening them, the support of the corresponding wheel must be brought to a position where the car's own weight acts on it

Subframe fixation

Certain assembly operations require the removal of the subframe or the entire front suspension. The initial position of the subframe relative to the body can be fixed using the fixing tools T10300. The prerequisite for the use of locking devices is rubber-metal bearings with a round hole for the fixing bolt. When mass production was launched, rubber-metal supports with square holes were installed; the position of the subframe with such supports is not fixed. Immediately before lowering the subframe or the entire front suspension, always install the locking devices. At the end of the repair, perform a test drive. If the steering wheel does not stand straight when driving in a straight line, it is necessary to perform RUUK.

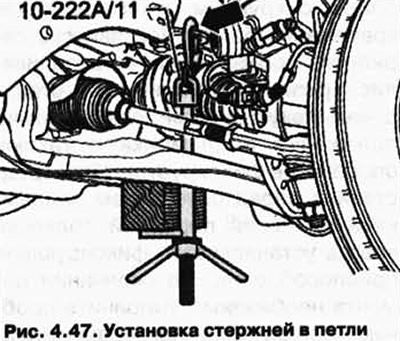

Remove the noise insulation under the engine/gearbox

Insert rods 10-222 A/11 into the hinges arrow of the engine bracket on the right and left sides (pic. 4.47).

Insert a piece of wood A, approx. 300 mm long, into the brackets of the rods 10-222 A/ 11 (pic. 4.48).

In this case, the brackets should be directed backwards.

Tighten the clamps of the rods, to do this, the wooden blocks must rest on the bracket of mounted units B.

Remove bolts 2 (pic. 4.49).

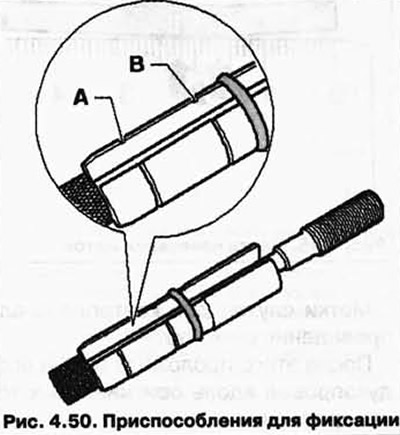

At these two points, «by hand», screw the fixing tools T10300 up to mark B (pic. 4.50).

Now tighten the locking devices to a torque of 30 Nm, while keeping the sleeve from turning with an open-end wrench.

The position of the subframe is now fixed.

Removal of fixing devices T10300 is carried out in the reverse order.

Tightening torques

Subframe to body: 120 Nm + 180°.

Visitor comments