Removing the outer hinge

Remove both clamps from the hinge boot.

Remove the boot from the outer hinge.

Separate the outer joint from the drive shaft by hitting the joint hard with a plastic mallet (pic. 3.179).

Removing the inner hinge

Remove both clamps from the hinge boot.

Remove the boot from the inner joint.

Separate the cover from the inner hinge (pic. 3.180).

Remove the circlip using a VW 161 A snap ring collet.

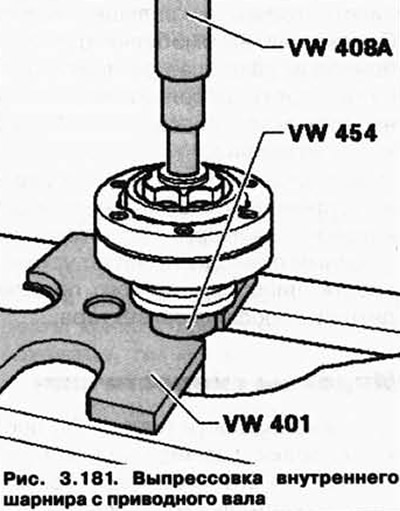

Press the inner joint off the drive shaft as shown. While doing this, hold the drive shaft firmly (pic. 3.181).

NOTE: The inner hinge cannot be disassembled for inspection.

Checking the outer hinge

The pivot should be disassembled to replace the grease if heavily soiled, or if the ball raceways need to be checked for wear and damage.

Removing

Before disassembly, mark the position of the spherical bushing relative to the cage and body using an electrograph or a finishing block.

Rotate the spherical bushing and cage.

Remove the balls one by one.

Remove the separator with the sleeve (pic. 3.182).

Rotate the bushing segment towards one of the separator windows (pic. 3.183).

Shake the sleeve out of the separator.

6 balls of each joint belong to one tolerance group. Check the axle trunnion, bushing, cage and balls for small indentations (surface defects) and badass. Too much lateral play in the hinge can be seen by beating when the load changes, in such cases the hinge must be replaced. The presence of grouts and ball paths is not a basis for replacing the hinge.

Installation

Inject half of the total amount of grease into the pivot housing (60 grams).

Insert the separator with the bushing into the hinge body.

Note the large chamfer on the inner diameter of the ball bushing and the large inner diameter of the cage, which must face the shaft when installed.

Insert opposite balls in turn, while restoring the previous position of the spherical bushing relative to the separator and the hinge body.

Distribute the remaining grease in the sealing collar.

Visitor comments