Dismantling

The following signs indicate a defective cylinder head gasket: water leakage, the presence of water in the oil, boiling of cooling water (do not turn off the engine, open the lock (in surge tank).

Disconnect the battery from the case.

Drain cooling water, see section "Cooler replacement".

Remove the air filter insert.

Remove spark plugs and distributor nozzles, see sections "Checking glow plugs" and next.

Remove toothed belt (only from above), see section "Removal and installation of a toothed belt".

Loosen and remove all water hoses on the cylinder head.

Unscrew the exhaust pipe, see section "Exhaust system".

Disconnect the electrical wires from the switch, spark plugs, oil pressure regulator and water temperature sensor, see also section "Dismantling the engine".

Clean the inlet pipes at the points of attachment to the injectors with gasoline and unscrew them. Close the openings with suitable plugs.

Unscrew the cylinder head cover.

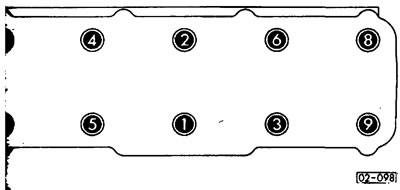

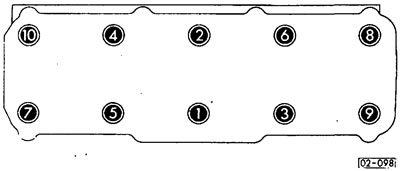

(02-098) Unscrew the cylinder head bolts in descending order of numbers, i.e. starting from 10.

Remove the cylinder head and head gasket.

Installation

Starting with the CS 000339 engine, the cylinder head is fastened with cylinder head bolts and internal teeth, although previously cylinder head bolts and hex bolts with M11 internal edges were used.

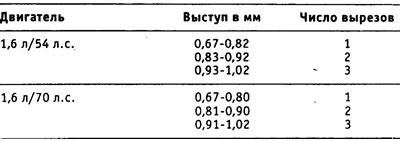

Attention! Depending on the size of the protruding part, three gaskets of different thickness are installed. When choosing a gasket, pay attention to the designation and use only a similar old gasket.

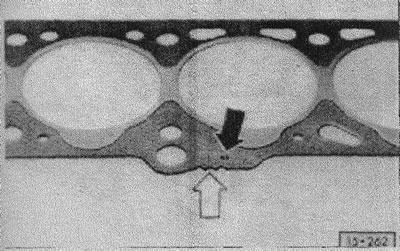

(15-262) Numbers are black arrow, cutout is white.

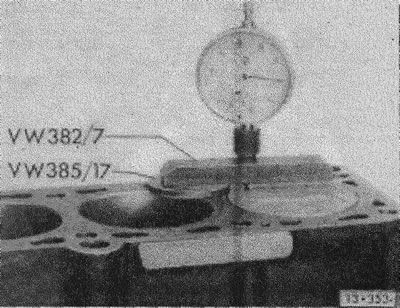

(13-353) If necessary, the thickness of the gasket can be determined. To do this, measure the piston protrusion at top dead center.

Attention! If different values are obtained when measuring the protrusions of the 4 pistons, then the largest value is taken into account.

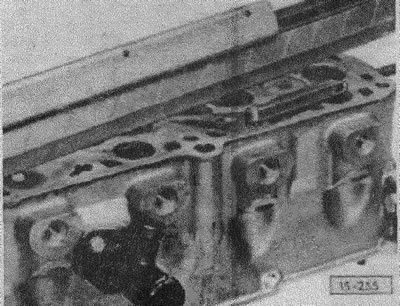

- (15-255) before installing the cylinder head, it must be checked for distortion. To do this, a steel ruler is placed on it and the curvature is measured in various places. Its value should not exceed 0.1 mm, otherwise the head must be replaced.

- before installing the head, the crankshaft is set to a dead center position, see also section "Removal and installation of a toothed belt". Then turn the crankshaft counterclockwise until all pistons are about the same level below top dead center.

- apply the appropriate cylinder head gasket using additional sealing agents. Put the head.

- to center the head in holes 7 and 9, screw the end bolts of the block head.

Attention! Always replace bolts with internal teeth. When tightening socket head screws, follow the instructions.

- Loosen the centering bolts and tighten the cylinder head bolts carefully.

- (02-098) With a cold engine, screw in the bolts with six internal edges in order from 1 to 10 with a torque of 50 Nm, then tighten them in order with a torque of 70 Nm. 8 completion tighten them in the same order with a torque of 90 nm.

Attention! Warm up the engine to an oil temperature above 50 degrees until the radiator fan turns on and, without first loosening them, tighten the bolts with a torque of 90 Nm, observing the order, see fig. 02-098.

Attention! After 1000 km of run, bolts with inner edges must be tightened with a cold engine. To do this, the bolts are loosened one at a time by an angle of about 30 degrees, and tightened to the prescribed torque. Thus, start with bolt 1, loosen it by 30 degrees, and tighten it with the corresponding torque of 90 Nm. Then they move on to the 2nd bolt, etc.

- socket head bolts with internal teeth are tightened in three stages in order to the prescribed tightening torque. Tightening torque for 1st stage is 40 Nm, for 2nd stage is 60 Nm (with a cold engine). At the 3rd stage, all bolts are tightened with a regular wrench by 1/2 turn (180 deg.), it is permissible to tighten 2 times 90 degrees.

Attention! Warm up the engine to an oil temperature above 50 degrees until the radiator fan turns on and, without first loosening them, tighten the bolts in one step with a regular wrench by 1/4 turn, observing the order, see fig. 02-098.

Determine the final angle of twist. Put on the valve, placing it along the cylinder head and turn. Until the handle of the key is crossed (90 deg.) or, respectively, on the other side along (180 deg) cylinder heads.

- After approximately 1,500 km of run, at the end of the repair, cylindrical bolts with internal teeth must be tightened. To do this, without prior relaxation, tighten the bolts in one go with a regular wrench by 1/4 turn (90 deg.), keeping order. The engine must be cold or warm.

- Apply a new gasket to the cylinder head cover. Install cover and tighten bolts to 10 Nm, install spark plugs, see relevant section, install spray nozzles, see relevant section.

- Clean the intake pipes with gasoline, tighten the union nuts.

Attention! When installing the cylinder head with the camshaft mounted, it is not necessary to adjust the valve clearance.

- Connect the electrical wires to the switch, oil pressure regulator and water temperature sensor.

- Screw the exhaust pipe to the exhaust outlet, use a new gasket.

- Connect all water hoses and secure with clamps.

- Pour in the coolant see related section.

- Install toothed belt see related section.

- Check the start of the fuel pump delivery, see related section.

- Install the air filter insert.

- Check the oil level in the engine.

- Attach the battery to the case.

Visitor comments