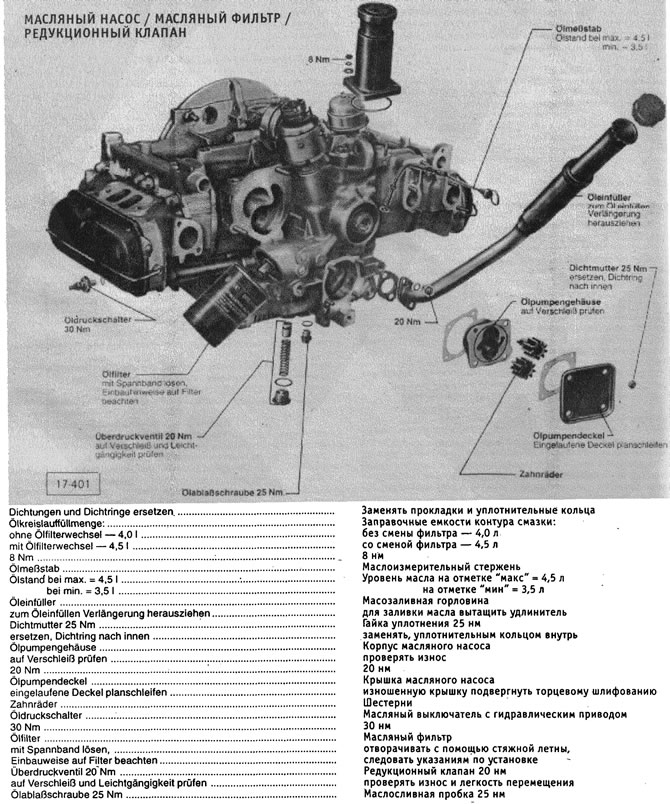

The pressure reducing valve located in the main channel regulates the oil supply to the lubrication channels, namely, under normal operating conditions, the valve piston is pressed against the upper stop by the force of the spring. Thanks to this, oil can freely enter through the main channel to the lubrication points. When the oil pressure reaches a certain value, the piston begins to overcome the force of the spring. This opens a bypass channel through which part of the supplied oil returns to the oil sump.

Oil cooler on some models

All 2.1 liter engines and 1.9 liter engines of the Syncro bus with all-wheel drive from 11.85 have an additional oil cooler located on the oil filter flange. The oil cooler is connected by hoses to the engine cooling system. Thanks to cooling, the oil wears out more slowly and the engine can better withstand increased loads.

Removing

Disconnect the water hoses with clamps from the oil cooler.

Unscrew the oil filter by hand or with a tie-down band.

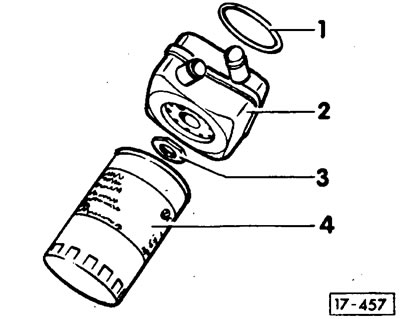

Remove bolt -3- and remove oil cooler from flange.

Installation

The O-ring -1- must be replaced.

Coat contact surfaces of oil cooler -2- with flange with sealing compound VAG AMV 188 100-02.

Install and screw on the oil cooler. Provide access to surrounding parts.

Screw on the oil filter in accordance with the installation instructions.

Connect water hoses and secure with clamps.

Fill with coolant.

Attention: If, during repair work on the engine, metal chips are found in a significant amount, as well as friction products (caused by damage from scuffing, for example, damage to the crankshaft bearings and connecting rods), in order to avoid consequences, along with a thorough cleaning of the lubrication channels, replace the oil cooler.

Visitor comments