Repair of hydraulic pushers is not possible. In case of defects, the pushers are replaced as a set.

Short-term valve knocks after starting the engine or during acceleration after a heavy load on the engine at high outside temperatures do not matter.

If, in case of damage, for example, main or connecting rod bearings, metal filings are found in the engine crankcase, sequentially disassemble and wash the pushers. In doing so, do not interchange individual parts. For disassembly and from the side, see section "Removal of air from pushers".

Basic adjustment

Attention: Carefully insert the pusher rods into the ball bearings of the pushers. Control with your finger. Tappet rods mounted on the end of the tappet lead to erroneous adjustment results and damage to the tappets when the engine is cranked.

After removing the rocker shaft, the following basic adjustment is required:

Loosen the basic adjustment screws in the rocker arms until they are behind the face with the rocker arms.

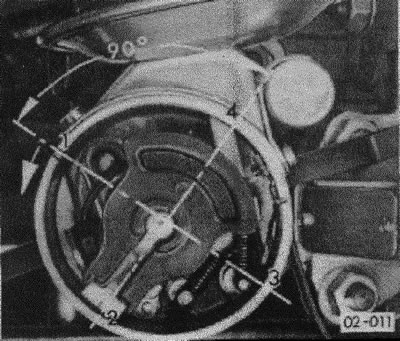

Set crankshaft to top dead center cylinder 1 (the ignition distributor slider must be turned towards the cylinder 1 mark on the ignition distributor housing). To do this, rotate the engine by the crankshaft.

Slightly screw in the adjusting screws of both rocker arms until they are pressed against the valves (valves have no gaps).

From this position, unscrew the adjusting screws two turns and lock.

To continue adjusting the rocker arms of the 2nd, 3rd and 4th cylinders, turn the crankshaft to the left until the ignition distributor slider is set to 90°each time.

Visitor comments