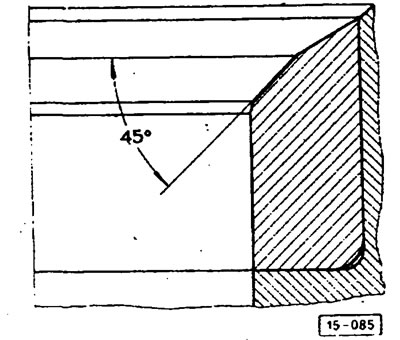

To ensure perfect centering, the 45°surface must be especially carefully machined. To avoid damaging the cylinder head prematurely, remove only enough material to cover the full width of the seat.

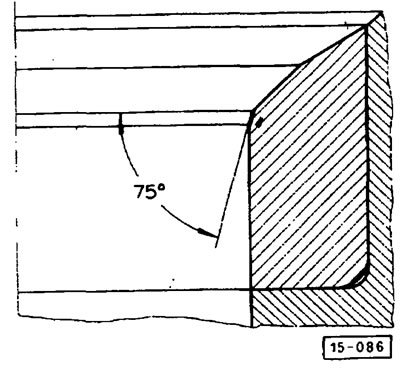

At a 75°surface, slightly cut the lower edge of the exhaust valve seat sleeve at this angle.

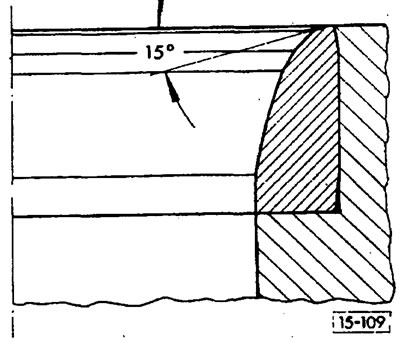

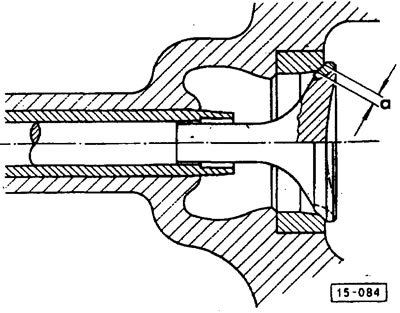

At 15°face, cut at this angle the top edge of the seat sleeve so as to obtain the following dimension "A".

Saddle Width "A" must be between 1.4 and 2.5 mm.

Visitor comments