The engine crankcase consists of two parts connected to each other at the level of the crankshaft and camshaft.

The four cylinders of the engine are of the same shape and can be replaced separately, together with the corresponding pistons, if necessary.

Each pair of cylinders has a common cylinder head made of light metal alloys. Four valves, one for intake and one for exhaust per cylinder, are located in the cylinder head. They can be replaced after removing the cylinder head. Both cylinder heads are absolutely symmetrical.

Since not all cylinders are in a row on a boxer engine, they are numbered starting from the cylinders located on the right side in the direction of travel and then counting continues from front to back.

The crankshaft is forged from steel and mounted on three main bearings. A fourth, smaller diameter bearing is mounted at the rear end of the shaft between the camshaft drive gear and the large belt pulley.

The camshaft is housed in the crankcase under the crankshaft and runs on three separate steel bearings with a tin-plated anti-friction alloy running surface. It is driven from the crankshaft through a helical gear and rotates twice as slowly as the crankshaft. To transmit the stroke of the cams to the valves, eight hydraulic pushers and push rods and four rocker levers are used. Thanks to the installation of hydraulic valve clearance compensators, clearance adjustment is not required.

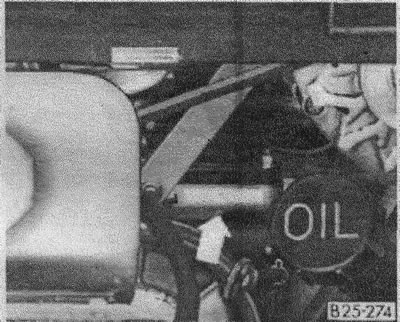

The lubrication circuit consists of a gear pump driven by a camshaft, an oil pressure relief valve, an oil cooler and a hydraulic oil switch.

The water pump is mounted on the side of the engine block. Care must be taken to ensure that the cooling system is filled with antifreeze and alkali-free water throughout the year. The preparation of the ignitable air-fuel mixture is carried out by a carburetor or fuel injection device, which usually do not require maintenance.

The ignition spark is formed in a transistorized ignition system that maintains the ignition timing constant. The ignition distributor is mounted on the engine block and is driven through the spline connection from the crankshaft.

Warning: The radiator fan may turn on by itself when the engine is stopped and the ignition is turned off. Due to stagnant thermal zones in the engine compartment, this can also happen repeatedly. When working in the engine compartment and a warm engine, be careful and be prepared for the sudden activation of the radiator fan.

Visitor comments