Removing

A special tool is required to remove the cylinders and pistons.

Remove engine.

Remove the exhaust system.

Remove cylinder head.

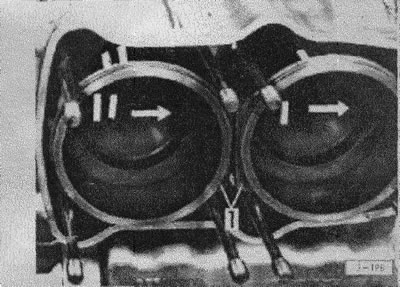

Mark the sides of the cylinders and piston heads with a clear cylinder number and an arrow pointing towards the flywheel for subsequent installation in the same position in the same cylinder.

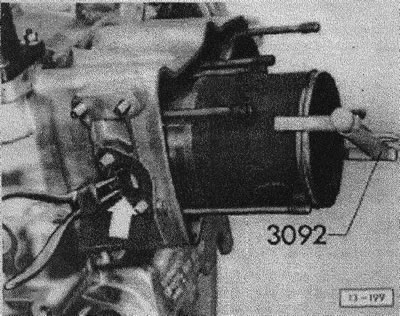

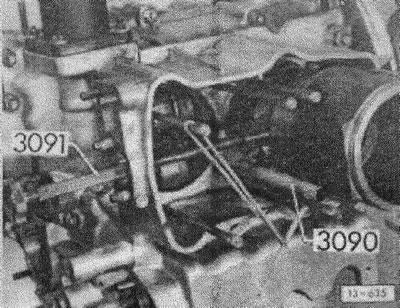

Turn the crankshaft to set the piston to top dead center. Pull the cylinder back with tool VAG 3092 until the hole for the piston pin is clear.

Remove the piston pin circlip.

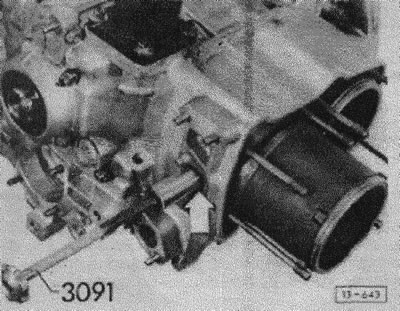

Using tool VAG 3091, remove the piston pin. Carefully remove the piston and cylinder, push the piston out of the cylinder.

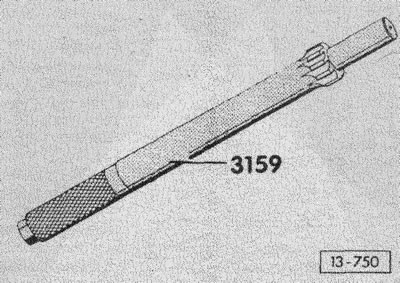

Note: If it is not possible to pull out the piston pin with tool VAG 3091, the impact of the piston pin against the retaining ring has caused seizing. In such cases, before removing, remove the scuffs with a VAG 3159 reamer.

Remove the piston pins with special pliers.

Installation

Before installation, wash all parts in clean gasoline. Remove deposits in the area of the cylinders in the crankcase and the cylinders in the cylinder head.

Check cylinder wear. If there are scratches or signs of wear, the cylinder is replaced. When replacing cylinders, pistons must be replaced, since the piston and cylinder in a pair must belong to the same size group.

The seating surfaces in the cylinder as well as the seating surfaces of the cylinders in the crankcase must be absolutely clean. Foreign particles can cause leaks and misalignment of cylinders.

When installing new cylinders and pistons, the following instructions must be observed.

Generally available as spare parts in 2 different size groups of cylinder-piston pairs (normal size and oversize). They differ in nominal diameters.

Each cylinder-piston pair of a certain diameter is further subdivided into two different size groups. These groups are distinguished by markings in the form of colored dots on the piston crowns and on the cylinder cooling fins (blue and pink).

Maximum weight difference in a new set of pistons (for 4 cylinders) should not exceed 10 g.

Therefore, there are pistons of two more different groups, which differ in markings on the bottom (minus or plus sign) and additionally colored dots % brown = (+), gray = (-).

Before installing old pistons, piston rings and cylinders, do the following: check the pistons, measure the gaps along the height of the piston rings, check the cylinder bores.

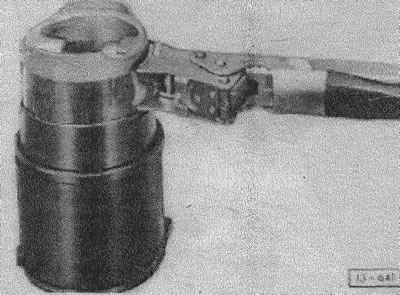

Insert piston rings only with special pliers.

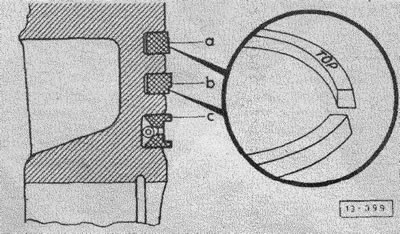

Pay attention to the design of the rings.

Be sure to replace the rubber sealing rings of the cylinders. On the side of the cylinder head, install a thin, green ring, and on the side of the crankcase, a thick, black ring.

Designation "Top" on the piston rings should face the piston bottom, a - upper piston ring, b - lower piston ring with a ledge, c - oil scraper ring.

On the side of the piston facing the flywheel, use special pliers to install the retaining ring.

Compress the piston rings with a compression band. The arrow on the piston should point towards the flywheel, and the joint of the oil scraper ring should be facing up. In addition, the piston ring joints must be offset by 180°.

Lightly lubricate the cylinder with engine oil and insert the piston into the cylinder.

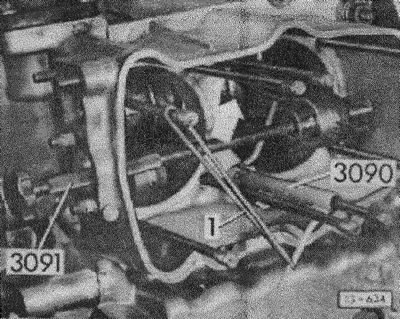

Put the VAG 3090 connecting rod support on the middle stud, rest it on the connecting rod profile and secure it with an elastic band -1- from jumping off.

Attention: Pay attention to the markings of the connecting rod supports. R = right side of the engine; L= left side of the engine.

Align the connecting rod so that the piston pin can be inserted into the hole in the housing.

The connecting rod bearing must point upwards -arrow-.

Install the piston pin with tool VAG 3091.

Use special pliers to insert the piston pin circlip.

Push the cylinder completely into the engine block.

Install the cylinder head.

Install the exhaust system.

Install the engine.

Visitor comments