Caution: If only the pusher protection tubes are defective or if the sealing rings of the pusher protection tubes have to be replaced, the removal of the cylinder head is not required. At service stations, there are telescopic protective tubes of pushers for further refinement of the engine.

Removing

The cylinder heads can be removed without removing the engine. In this case, you only need to first drain the coolant.

Unscrew the engine cover from below.

Disconnect the spark plug caps.

Remove muffler and both exhaust pipes.

Remove intake manifold with carburetor.

Wash the engine in gasoline, especially in the area of the cylinder heads.

Caution: Fire hazard, do not make open flames.

Unscrew the coolant pipe from the right cylinder head and pull it out of the left cylinder head,

On the left cylinder head, remove the water hose to the cylinder head from the coolant temperature sensor flange.

Disconnect the ground wire from the left cylinder head.

Use a powerful screwdriver to press the cover clamp down.

Remove cover and rinse before installation.

Loosen the 2 rocker shaft mounting bolts.

Remove the rocker shaft.

Pull out the pushers.

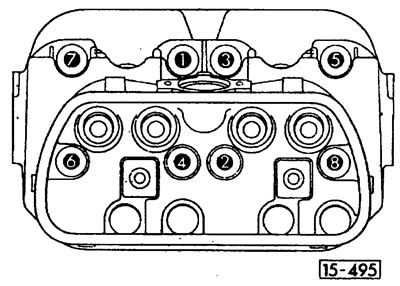

Loosen 8 nuts (see location in section "Installation") and remove with washers.

Remove the cylinder head-with gasket to the protective tubes of the pushrods.

Attention: If the hydraulic tappets are also removed, they must be marked so that they can be reinstalled in the original holes. Crushed pushers should be stored with the bottom of the pusher down.

Installation

Before installation, remove deposits in the cylinder/cylinder head area.

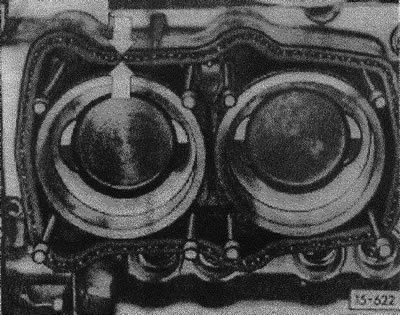

The seal between the cylinder and the combustion chamber is achieved in each cylinder by the installation of a metal O-ring. These O-rings must be replaced at every disassembly.

Before installing, check the cylinder head for cracks in the combustion chambers and exhaust passages. The contact surfaces of the cylinder linings and the intake manifold flange should also be checked. Damaged heads are replaced.

If there are small cracks (0.5 mm) between the valve seat sleeve and the thread of the spark plug hole, or if only the first threads of the thread of the spark plug holes are broken, the heads can be installed on the engine.

If the hydraulic tappets were removed, insert them in their original places in accordance with the markings made. Check pushers first.

Check the integrity and reliability of the threaded spark plug holes and studs. Damaged or overtightened threads are repaired with Heli-Coli thread inserts.

If the rocker shafts were disassembled, check the wear of all parts. Replace damaged parts and assemble.

Check tappets for bending. The runout should not exceed 0.3 mm. To do this, put the pushers on a flat surface and use the probes to measure the runout.

If there are scratches on the working surface of the rocker arms and support posts, they can be removed with a thin sandpaper. To do this, put the skin on a flat surface.

Before installation, arrange the old protective tubes of the pushers to the desired size.

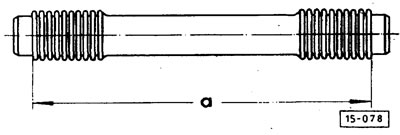

Tighten the protective tubes of the pushers. Size "A" is about 194 mm.

Carefully install cylinder head with new metal O-rings. When fitting the pusher protection tubes, make sure that the O-rings fit correctly between the engine crankcase and the protection tube and between the cylinder head and the protection tube.

Attention: Install new O-rings for the protective tubes of the tappets.

Turn the protective tube with the seam upwards.

For better sealing of unpainted or painted contact surfaces on the cylinder head, sealing compound VAG D 000400 is used.

In case of damage to the paint, treat the contact surface of the cylinder head on the crankcase with fine sandpaper.

Rinse contact surfaces with gasoline.

Apply a layer of sealant 1-2 mm thick in the middle of the gasket -arrows-. To do this, cut the syringe tube obliquely.

Attention: Do not apply too thick a layer of sealant. It can clog the coolant passages in the cylinder head.

The cylinder head must be tightened no later than 45 minutes after applying the sealing compound.

Install the cylinder head with a new gasket. Make sure the cylinder head gasket is properly seated.

Tighten the cap nut on the stud -1- without shims until the rest of the nuts with shims can be screwed in by hand.

Attention: Cover the cleaned and degreased contact surfaces of the cap nuts and washers with sealing compound VAG AKD 45600001 and pre-tighten in the correct sequence - from 2 to 8 - to a torque of 10 Nm.

Remove cap nut from stud -1-. Clean and open the washer on both sides of AKD 45600001 and pre-tighten the nut to 10 Nm.

Attention: Make sure that the protective tubes of the pushers are seated correctly.

Finally tighten the cap nuts with a torque wrench from 1 to 8 to a torque of 50 Nm.

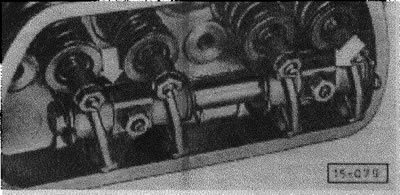

Push the pushrods in and slide the rocker shaft onto the dowel pins.

Attention: Carefully insert the pusher rods into the ball bearings of the pushers. Control with your finger. Tappet rods mounted on the end of the tappet lead to erroneous adjustment results and damage to the tappets when the engine is cranked.

Before installing the rocker shaft, unscrew the adjusting screws for the basic adjustment until they are flush with the rocker arms.

Attention: Care must be taken to ensure that the slots in the support legs (arrows) were turned upward.

Use M8 nuts for fastening. Tighten the nuts to a torque of 25 Nm.

Perform basic valve clearance adjustment.

Install intake manifold with carburetor.

Install water hoses.

Fill with coolant.

Install the exhaust system.

Install the ground wire for the left cylinder head.

Put on spark plugs.

Screw the bottom guards under the vehicle.

Check engine oil level.

When the operating temperature is reached, check the coolant level and top up if necessary.

Check idle speed and readjust if necessary.

After a test drive, check for coolant leaks and, if necessary, tighten the hose clamps.

Removal of air from pushers

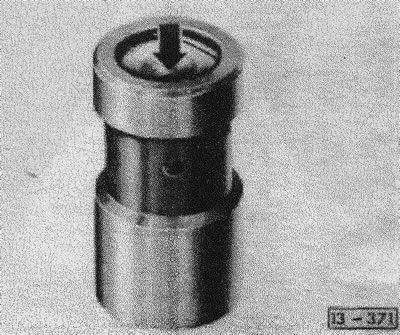

Tappets with valve clearance compensation after installation must be checked for air inclusions in the working chamber. To do this, a test by pressing a finger is enough. The piston should not give in to strong finger pressure (in the direction of the arrow). Otherwise it is necessary to remove air from a pusher.

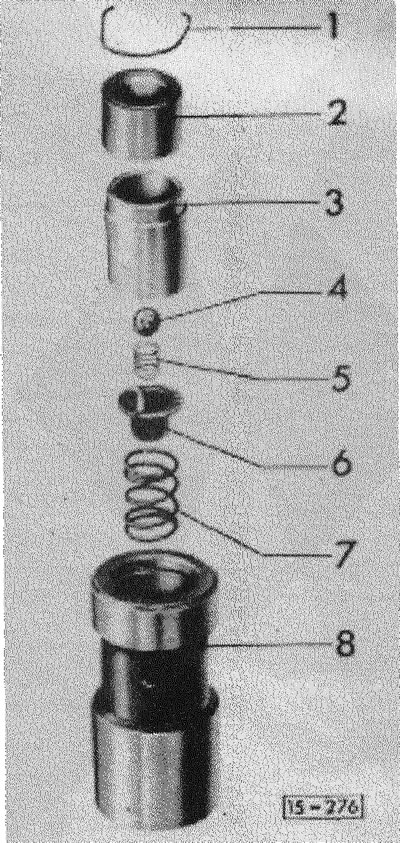

Pull out the retaining ring -1- and remove the bushing of the pusher rod -2-, the piston with the valve -3,4,5,b- and the valve spring -7-.

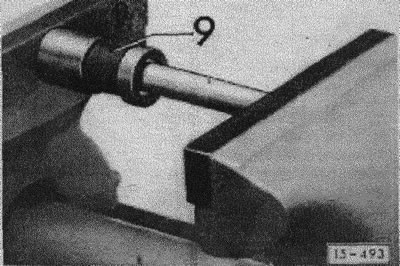

Fill tappet -8- up to hole -9- with oil.

Insert spring -7-.

Insert piston -3- with valve -4,5,6- and press down. In doing so, open the ball valve -4- with the valve.

Insert push rod bushing and valve guide or cut push rod ha and squeeze as much in a vice (hole -9- up) or in a repair press so that the circlip -1- can be inserted.

Insert circlip -1-.

Visitor comments