Removing

Disassemble the engine crankcase.

Pull out the camshaft.

Pull out the crankshaft and bearing shells and remove bearing 1 from the flywheel side. When removing the crankshaft, make sure that the adhered bearing shells do not fall off or become damaged. Mark bearing shells.

Remove rods.

Disassembly

Clamp the crankshaft in a vise.

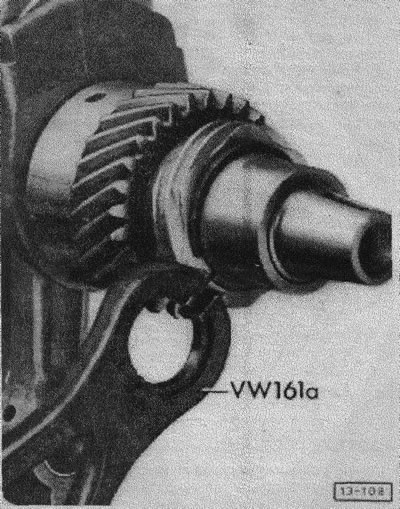

Remove the belt pulley key and remove the bearing 4 together with the oil flinger.

Remove the circlip from the ignition distributor drive gear.

Installation

The lubrication holes of the shaft journals and bearings must not have sharp edges.

If there are foreign metal particles on the working surfaces of the bearing shells, they should be carefully removed with a scraper. Do not damage the bearing shell itself.

New liners should not be processed.

Check the tightness of the pins in the places where the bearings are installed in the crankcase.

Insert bearing shell halves 2.

Lubricate bearing 1 with engine oil and put it on the shaft so that its pin holes face the flywheel.

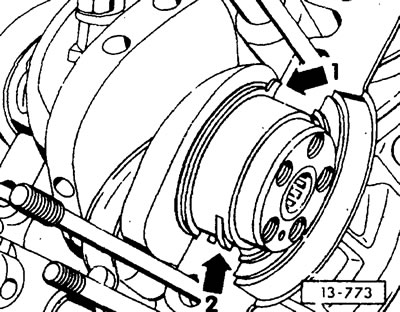

Installation of bearing 1 of the crankshaft on exhaust engines from 11.85

From 11.85, modified crankshaft bearing shells 1 are installed. When installing, the fixing lug of the camshaft washer -1- must face the crankshaft bearing and the connection surface of the crankcase, see illustration.

The fixing projections of the bearing 2 of the crankshaft must go into the recess in the crankcase. In this case, the lubrication holes must face the left half of the crankcase.

Attention: Crankcases for engines with a working volume of 1.9 liters of production up to 11.85 are no longer produced. Instead, a new single crankcase should be installed (for engines with a working volume of 1.9 l and 2.1 l). At the same time, they are replaced with parts of a new type: new crankshaft bearing shells 1, 2 and 3, as well as bearing accelerating washer 1.

Insert the crankshaft making sure that all the pins fit well into the bores of the individual bearing shells.

When installing the crankshaft, pay attention to the timing marks on the camshaft.

Assemble the engine crankcase.

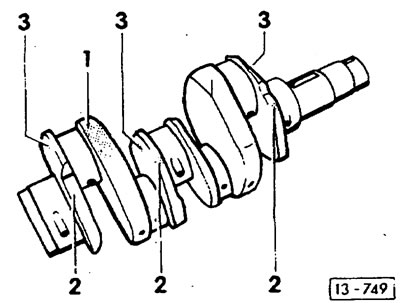

Crankshaft marking

When replacing the crankshaft and / or bearing shells, only parts of the same size group should be installed. To do this, a blue or red dot is applied on sides -2- of the crankshaft.

Attention: If there are no colored dots here, they are marked on side -3-.

Marking of bearing shells from 1 to 3 of the crankshaft. If the number 001 is stamped, the liner is suitable for installation with a crankshaft with a blue mark, with a number 004, it is suitable for installation with a crankshaft with a red mark.

Crankshafts of engines with a working volume of 2.1 liters are additionally marked with a green dot in place -1-.

Visitor comments