Removing

Disassemble the engine crankcase.

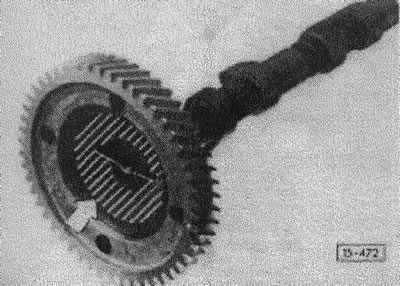

Pull out the camshaft. Pay attention to stuck bearing shells, which may fall off.

Pull out and mark the bearing shells.

Examination

Check the reliability of the fastening of the gear on the camshaft.

Check the absence of wear on the bearing seats and cams, whether there is oblique wear or non-flatness of the working surfaces.

Check camshaft gear teeth for wear.

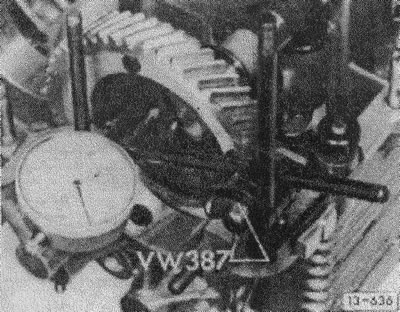

Check the backlash of the gearing of the gears of the crankshaft and toothed shaft. The backlash should be in the range of 0.00-0.05 mm. The only way to fix the backlash is to install a new camshaft.

The camshaft is correctly sized if, when rotated gently in both directions, there is barely a play between the two gears when changing directions. The play is too small if the camshaft lifts the crankshaft out of its bearings during reverse rotation. In case of increased play, a camshaft of a different size group can be installed. Numbers are stamped on the sides of the camshaft gears facing the cams to distinguish sizes. For example, -1, 0, +1, +2, etc. The number means how many hundredths of a millimeter the radius of the pitch circle of the gear differs from the size group 0.

Attention: number "0" not to be confused with letter "ABOUT", which serves when marking the gears of the gas distribution mechanism drive. There are no markings for the crankshaft gears.

Installation

Different engines have different camshafts. Engine index DF: white; release DG before 10.85; not painted; DG, SP since 11.85: green; MN, DJ: blue.

Before installation, the camshaft runout must be checked at a service station. The runout, measured in the middle of the camshaft, can be a maximum of 0.04 mm.

The axial play of the camshaft must not exceed 0.16 mm.

If necessary, slightly remove the edges of the bearing seats.

Insert bearing shells 1-3 (counting from flywheel side) so that the protrusions enter the recesses in the engine crankcase, bearing 3, as a leading bearing, perceives axial forces and therefore has a spacer lug on both sides for the camshaft.

Lubricate the bearing seats and camshaft cams with engine oil and insert the camshaft so that the gear tooth marked "0", was between both marks on the crankshaft gear.

Visitor comments