Removing

Remove belt pulley.

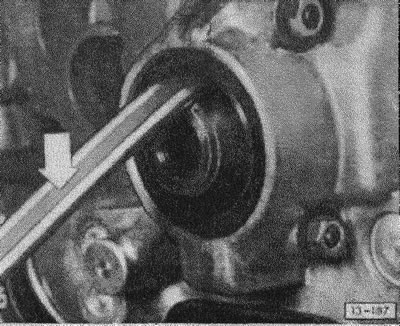

Carefully pull the oil seal out of the crankcase with a pry bar -arrow-.

Installation

Lubricate the new oil seal and install it using tool VAG 3088 (on the car Syncro tool VAG 3162) and slightly tighten the belt pulley bolt without the washer. Then install and tighten the belt pulley bolt with washer. If there is no special tool, carefully drive the stuffing box with a pipe of the appropriate diameter and lightly tap it with a hammer until it stops.

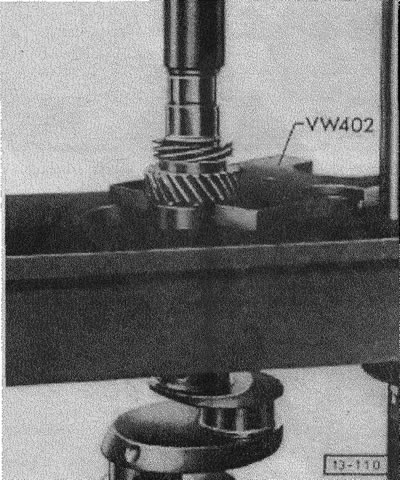

Compress the distributor drive gear, intermediate ring and crankshaft sprocket together on a press and remove the keys.

Remove bearing 3.

Clean the crankshaft and blow out the oil passages with compressed air. Then immediately lubricate all bearing journals with engine oil to prevent corrosion.

Check for cracks on the crankshaft. To do this, check the shaft for sound by hanging the crankshaft vertically on a wire and lightly hitting it with a hammer. In this case, pure metallic sounds should be heard.

Check for signs of wear on the crankshaft. Light marks on the necks can be carefully removed without damaging the interference fit. If necessary, grind or replace the crankshaft.

Inspect the holes of the ignition distributor drive gear and the camshaft sprocket for scoring and check the appearance of the working surface of the teeth.

Check the tightness of the pins.

Assembly

Wash the crankshaft with gasoline and blow out the lubrication channels with compressed air.

Lubricate with engine oil and put on the bearing 3.

Insert the keys of both drive gears.

Heat both gears to approx. +80°C in an oil bath. Put on the heated camshaft gear with a chamfer to the bearing 3.

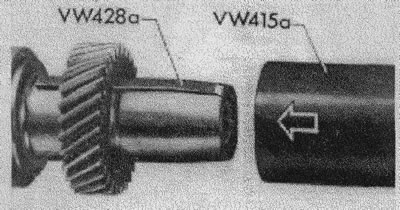

A bushing and a guide wedge are required to fit the crankshaft gear and the ignition distributor drive gear. The guide wedge is necessary to give the groove in the drive gear the correct position for the hat.

Put on the intermediate ring.

To put on the heated drive gear of the ignition distributor also with the help of the sleeve and the guide wedge. After cooling down, check the fit.

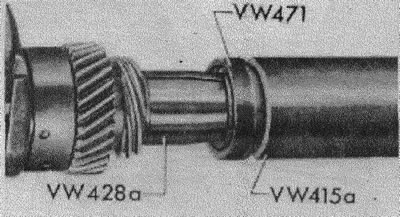

Put on the retaining ring. To do this, a tapered bushing is mounted on the bearing neck so as not to damage the surface of the neck.

Lubricate with engine oil and put on the bearing 4. The ring and the groove in the bearing should face the oil flinger.

Fit the oil slinger with the hollow side out. Insert the belt pulley key.

Install rods.

Visitor comments