Dismantling

Remove gearbox, see next section.

Attention! For vehicles with all-wheel drive, the engine must be removed instead of the gearbox. Then this labor cost will be less.

If, after disassembly, the clutch will be installed again, then before disassembling the pressure plate, it is necessary to mark it and the flywheel.

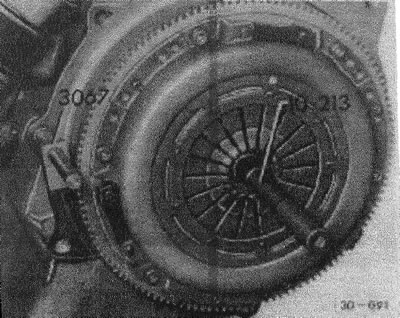

(30-091) Unscrew the hexagon bolts of the pressure plate crosswise in several stages, one or two turns each.

To prevent the flywheel from rotating when unscrewing the bolts, lock it by the bolt with a screwdriver.

Pull out the pressure plate with the drive plate.

Blow out the flywheel inside or wipe it with a rag soaked in gasoline.

Examination

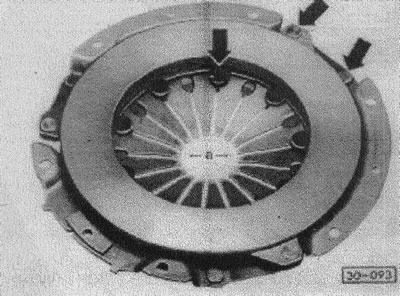

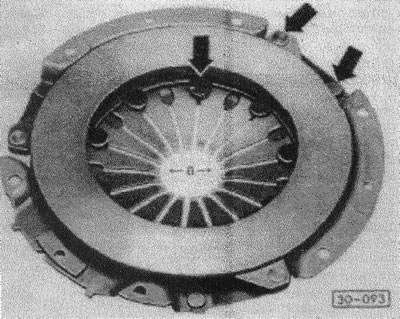

(30-093) before installation, check the key connection between the pressure plate and the cover for cracks, check the reliability of the rivet fastening.

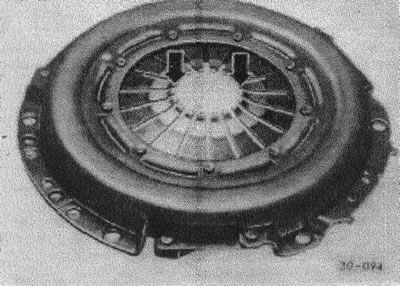

(30-094) check the ends of the membrane springs. Run-in marks up to 0.3 mm deep are acceptable.

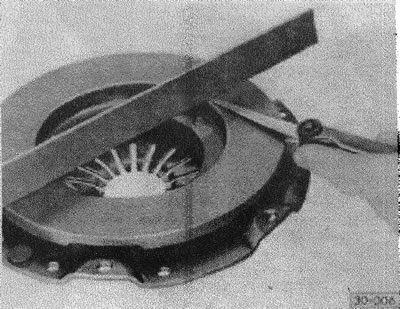

(30-006) check the contact surface of the pressure plate for scratches, burns and wear. Discs that are concave inwards up to 0.3 mm should not be installed. Checking is carried out using a steel ruler and a template.

In the workshop, the clutch disc can also be checked for lateral play. This check is only necessary if the clutch is to be installed again and it was previously disassembled incorrectly. Lateral runout can be no more than 0.5 mm.

Clean the finely splined profile of the transmission shaft and clutch disc from corrosion and abrasion products and lubricate with a thin layer of grease G 000 100.

Attention! Excess grease must be removed so that it does not get on the coupling coatings.

Check the release bearing. The bearing does not require maintenance. It should never be washed with gasoline or other cleaning agents. Simply wipe the bearing with a clean cloth.

Lubricate the guide sleeve of the disengaging bearing lightly with MoS paste.

Lubricate the flywheel needle roller bearing with a small amount of MoS2 grease when cleaning it.

Moisten the felt ring lightly with engine oil, wipe off excess oil.

Installation

Attention! When replacing engines, gearboxes or clutches, make sure that the diameters of the decoupling bearings and diaphragm springs match.

Under no circumstances should a bearing with a diameter of 46 mm be fitted together with a clutch with a diameter of 55 mm.

Only bearings that can be used with both sizes are available as spare parts.

(30-093) a = 46 mm or 55 mm.

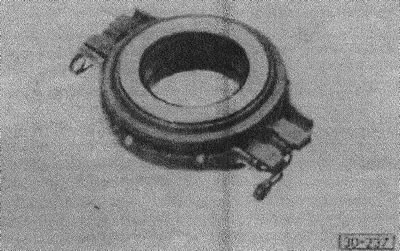

(30-237) release bearing for clutch with a = 46 mm.

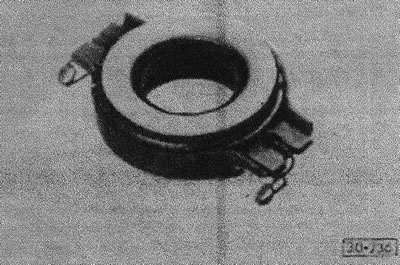

(30-236) release bearing for coupling with a = 46 mm or 55 mm.

Install clutch disc and pressure plate. An old drive shaft can be used to center the clutch disc.

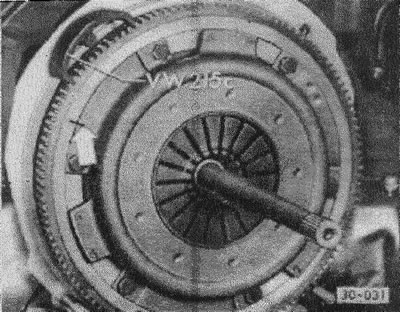

(30-031) when installing the old clutch, pay attention to the markings on the clutch and flywheel, applied during dismantling.

Tighten the fixing screws evenly and crosswise to 25 Nm. When tightening, lock the flywheel with a screwdriver.

Attention! Install cylindrical bolts M8x16 without a spring washer, and bolts M8x18 with a spring washer,

Install gearbox, see below.

Visitor comments