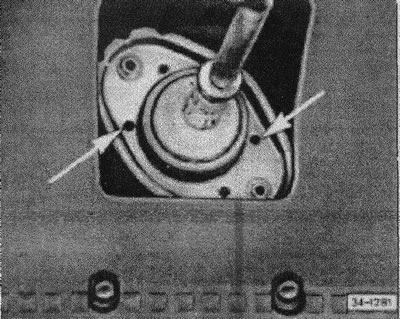

(34-1281) cars up to 5.88: the holes of the compensating support and the bearing of the gear lever, shown by the arrows, must be on top of each other.

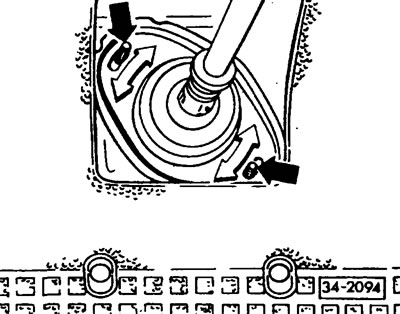

(34-2094) vehicles from 6.88: unscrew the fixing nuts and turn the gear lever bearing to the right or left as far as it will go. Nuts are not shown for clarity. The fixing bolts of the compensating support must touch the elongated holes on opposite sides (shown by arrows).

Tighten the nuts with a torque of 10 Nm.

Attention! The modified handle bearing can be mounted in models from 10.82.

Put the car on the goats.

Remove the protective bath below.

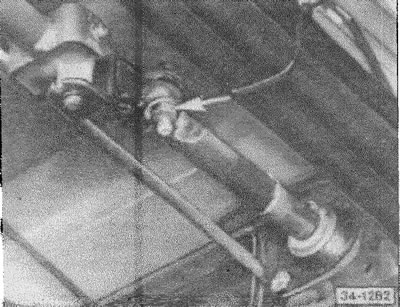

(34-1282) remove the clips indicated by the arrows. The linkage joints should move easily.

Remove spare wheel.

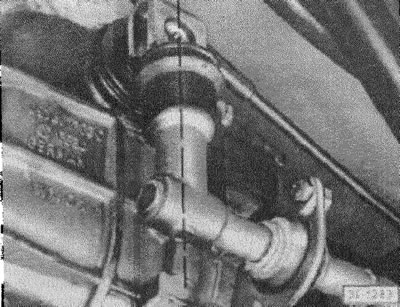

(34-1283) place the lever vertically.

Place the thrust pin of the front link in the middle of the thrust plate.

4 speed gearbox

(35-679) set distance a = 23 mm. For models with a production date before October 1982, a = 22 mm, up to chassis number 25 VN 137156 a = 19 mm.

Before tightening the clamp, turn the rear link to the left so that the left cheek of the casing rests on the upper sphere.

Attention! Do not press down on the shaft. In this position, tighten the clamp with a torque of 25 Nm. Fit the bolt with locking element D6.

Install protective bath.

The distance between the gearshift handle in the 1st gear position and the casing of the heating system must be at least 15 mm. If this is not the case, move the handle bearing in the elongated holes back a little.

Try all the gears, they should switch easily and without jamming. Pay special attention to the operation of the reverse gear lock.

5 speed gearbox

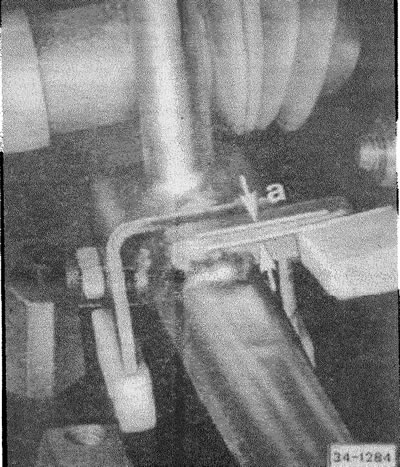

(34-1284) Install the rod to the right in the groove 1st gear/reverse and shift in the longitudinal direction so that the distance between the reverse stop and the stop lug of the rod is a = 3.0 mm. Measure the size with a piece of sheet metal 3.0 mm thick.

Attention! The gear should be at idle, the handle in a vertical position.

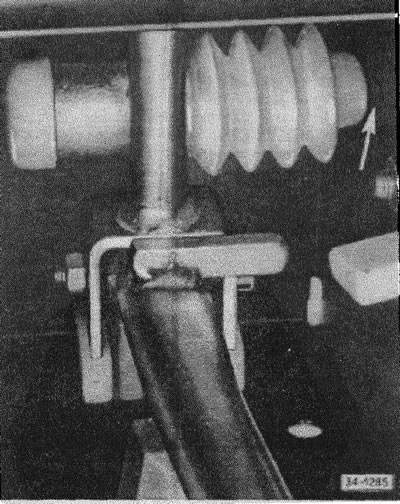

(34-1285) Install the gearshift rod in the groove 2nd/3rd gear and press slightly to the right (the plastic bellows must rest on the right, as shown by the arrow).

In this position, tighten the clamp with a torque of 25 Nm. Fit the bolt with locking element D6.

The distance between the gearshift handle in the 2nd gear position and the casing of the heating system must be at least 15 mm. If this is not the case, move the handle bearing in the elongated holes back a little.

Try all the gears, they should switch easily and without jamming. Pay special attention to the operation of the reverse gear lock.

Visitor comments