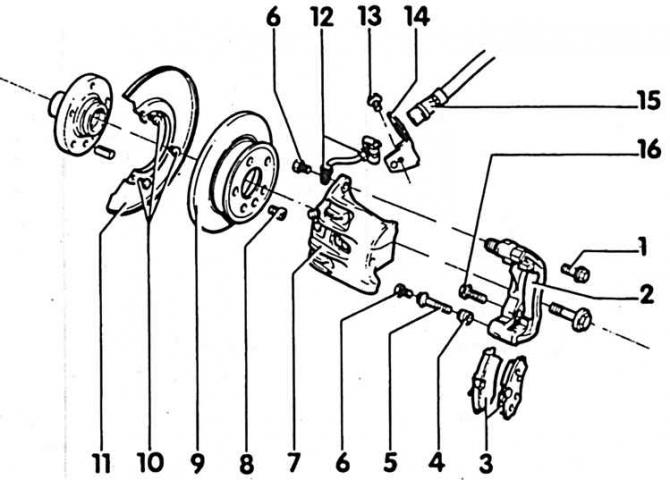

Front wheel brake (wheels 14 inches)

1. Screw, 160 Nm; 2. Brake support; 3. Brake pads with lining; 4. Protective cap; 5. Guide pins; 6. Screw, 35 Nm; 7. Brake housing (saddles); 8. Screw, 10 Nm; 9. Brake disc. Replace both on axles; 10. Screw, 10 Nm; 11. Protective fence; 12. Brake pipeline; 13. Screw, 10 Nm; 14. Bracket; 15. Brake hose; 16. Screw, 270 Nm

Removing

1. Loosen the wheel bolts with the machine on wheels.

2. Mark with paint the position of the disc on the wheel hub in order to reinstall the balanced wheel in its original place.

3. Put the car on the goats (jack) and remove the wheels.

Attention! If the brake pads are to be installed again, they must be marked before removal. Replacing the brake pads from outside to inside and vice versa, as well as from the right to the left wheel, is not allowed. Replacement may result in uneven braking effect. It is recommended to use brake pads approved only for this machine. All disc brake pads must be replaced at the same time, even if only one pad has reached the wear limit.

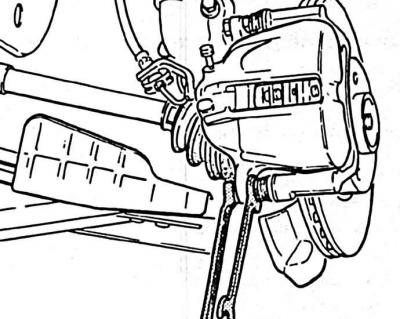

4. Unscrew the lower screw securing the brake housing, while holding the guide pin with an open end wrench.

5. Swing the brake housing up. Take out the brake pads.

Installation

Attention! When the brake pads are removed, do not depress the brake pedal: otherwise the piston will be squeezed out of the cylinder body. If the piston is squeezed out due to an oversight, install it again. At the same time, dirt must not penetrate into the hydraulic system. Then release the air from the brake system.

1. Clean the guide surface and the places where the pads are installed in the housing shaft with a soft metal brush or wipe it with a rag soaked in gasoline. Do not use solvents containing mineral oils on sharp instruments.

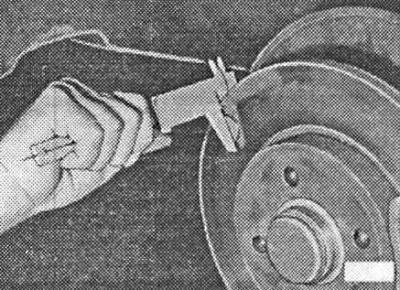

2. Before installing the pads, it is necessary to examine the brake disc by touch for the absence of grooves. Furrows can be trimmed (at the factory), if they are still thick enough. Always trim both brake discs, paying attention to sufficient wear reserve. If one brake disc is to be adjusted, then the other must be adjusted in the same way.

3. Measure the thickness of the brake discs (see subsection 7.5).

4. Check for cuts on the dust cap. Replace the damaged one, as the penetrating dirt will quickly lead to depressurization of the brake mechanism, after which the brake mechanism (saddle) will require removal and disassembly (factory work).

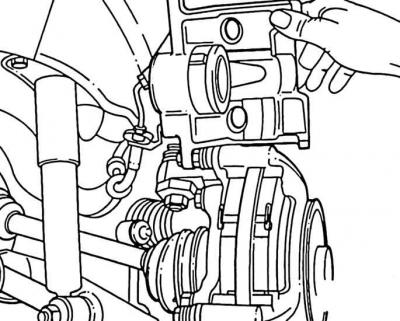

5. Press the piston back with a press tool. This can also be done with a hammer handle, made of hard wood. When doing this, pay special attention to ensure that the piston is not distorted and that the surface of the piston is not damaged, and that the dust cap is not damaged.

Attention! When the piston is pressed in, the brake fluid is squeezed out of the brake cylinder into the expansion tank. Observe the liquid in the tank, if necessary, suck off the excess with a rubber bulb.

6. For suction, you can use an air release bottle or a plastic bottle with a nipple that only comes into contact with the brake fluid. Do not use drinking bottles! Brake fluid is poisonous and must never be sucked in by mouth through a tube. Use a rubber bulb.

7. After replacing brake pads "max" on the expansion tank must not be exceeded, as the liquid expands when heated. Leaked brake fluid will drain onto the brake master cylinder, damaging the paintwork and causing corrosion.

Attention! In case of severe wear of the brake pads, check the ease of movement of the piston. To do this, insert a wooden rod into the brake mechanism, with assistance, slowly depress the brake pedal. The piston must be free to squeeze out and press in. To check it is necessary to install a new brake mechanism. Pay attention to the fact that the piston does not come out completely. If the piston stroke is difficult, it is necessary to repair the brake mechanism.

8. Install both brake pads into the brake caliper. When doing this, make sure that the compression springs are evenly up and parallel to the top edge of the block.

9. Lower the brake housing down and secure it to the brake mount with a new self-tightening screw to 35 Nm while holding the guide pin.

Attention! Each set of VW brake pads uses a self-locking screw to secure the brake housing. These screws must always be installed.

10. Screw on the wheel, paying attention to the markings. Remove the car from the goat (jack) and tighten the wheel bolts crosswise to 160 Nm.

Attention! Squeeze the brake pedal firmly and repeatedly in place until a noticeable resistance appears. This is the centering of the brake pads, which occupy a place corresponding to their working position.

11. Check the brake fluid level in the expansion tank, top up if necessary "max".

12. Grind new brake pads carefully, to do this, repeatedly brake the car from about 80 km / h to 40 km / h with a slight effort on the brake pedal, allowing the brakes to cool between braking.

Attention! Earlier than after 200 km it is impossible, unnecessarily, to produce a sharp and complete braking.

Visitor comments