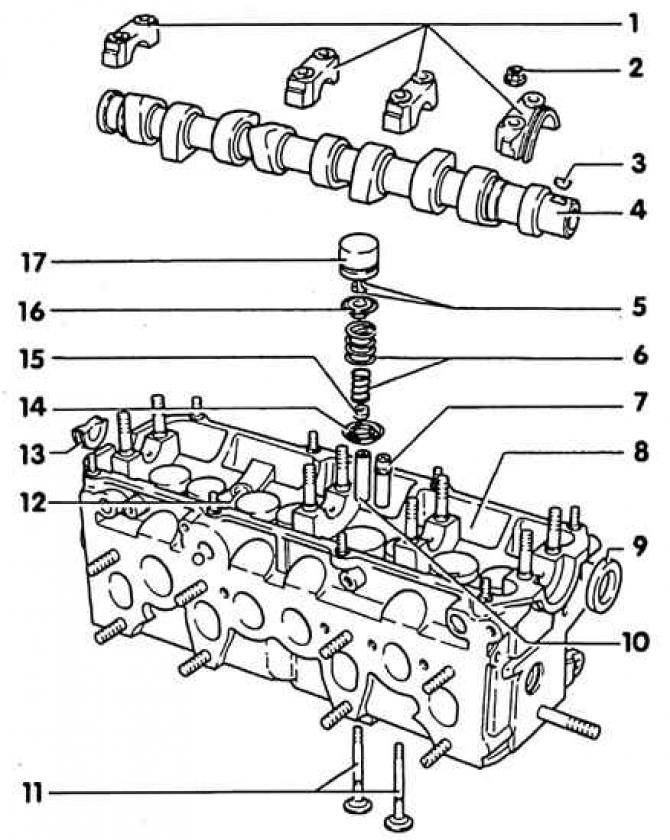

Camshaft and valve drive of a 4-cylinder gasoline engine

1. Main bearing caps; 2. Nut, 20 Nm; 3. Key (working without tightening); 4. Camshaft; 5. Valve cotters; 6. External and internal valve springs; 7. Valve guide. Repair version with shoulder; 8. Cylinder head; 9. O-ring; 10. Valve guides; 11. Valves; 12. Plug; 13. Plug; 14. Lower plate of the valve spring; 15. Oil scraper cap; 16. Upper plate of the valve spring. Designation: wide chamfer outside, chamfer inside; 17. Hydraulic poppet

4-cylinder petrol engine

Removing

1. Remove upper toothed belt cover.

2. Remove the cylinder head cover.

3. Set crankshaft to TDC for cylinder 1 (see subsection 2.5.2).

Attention! Do not change the position of the engine crankshaft any more.

4. Loosen the toothed belt and remove from the top of the camshaft gear (see subsection 2.5.1.1).

5. Seal the camshaft at the front with a spike. To do this, insert a suitable spike or a sturdy screwdriver into the hole in the camshaft gear and rest against the upper edge of the cylinder head. In order to avoid damage to the sealing surface of the cylinder head, place a piece of wood underneath. Holding the screwdriver firmly, loosen the camshaft mounting bolt. Unscrew and remove the camshaft gear, if necessary, hammer it in with light blows from a rubber mallet. Remove the key from the camshaft.

6. Mark all main bearing caps. Four covers, from right to left, looking in the direction of travel, mark with numbers from 1 to 4.

7. Remove caps 1 and 3. Then unscrew caps 2 and 4 alternately crosswise.

8. Take out the distributor.

Attention! If poppets are removed, they must be marked so that they can be installed again in their original places. Folding poppets with sliding surface (shifting towards the camshaft) down.

Installation

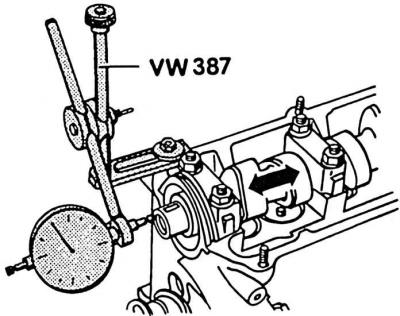

1. Before installation, if necessary, you can check the runout of the camshaft in the factory. Wear limit: 0.01 mm.

2. If the old camshaft is reinstalled on an engine with high mileage or noise in the valve drive, it is recommended to check the axial clearance. Wear limit: 0.15 mm. The measurement is taken with the poppets removed and the first and last main bearing caps installed.

3. Install a new camshaft O-ring. Lubricate the lips and the outer edge of the O-ring with oil first.

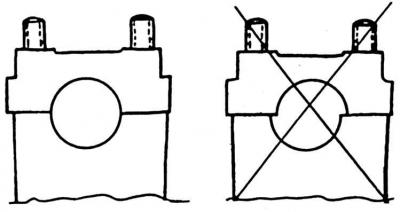

4. Make a trial installation of the bearing caps, paying attention to the position of the centers. The covers must be installed so that the holes of the covers and the cylinder head match. At the same time, pay attention to the labels.

5. If poppet pushers were removed, install them in their original places. Lubricate the poppet tappets with a thin layer of oil and do not distort during installation.

Attention! Poppet pushers must not be interchanged!

6. Lubricate with oil and install the camshaft.

Attention! In this case, the cams of cylinder 1 must be directed upwards. Install bearing caps according to marks. Pay attention to the position of the centers.

7. Tighten covers 2 and 4 crosswise to 20 Nm.

8. Install covers 1 and 3 and tighten to 20 Nm.

9. Install the camshaft key. Install the drive gear and tighten to 80 Nm while holding the sprocket with the pin.

10. Slide the toothed belt onto the camshaft sprocket, paying attention to the correct position of the intermediate shaft and vibration damper (see subsection 2.5.2).

11. Tighten toothed belt (see subsection 2.5.1.1).

12. Install a new cylinder head cover gasket by carefully tightening the cover bolts to 10 Nm.

13. Install the toothed belt guard.

Attention! If new poppets are installed, the engine must not be started for about 30 minutes, otherwise the valves will hit the pistons!

Visitor comments