Removing

1. Place the machine on stands.

2. Remove the lower engine compartment mudguard.

3. Moisten all bolts and nuts of the exhaust system with rust remover and leave for a while.

4. Remove the exhaust silencer or exhaust pipe.

5. Disconnect the additional muffler from the front pipe, having previously released the exhaust system from the suspensions.

Gas engine

6. Unscrew the front exhaust pipe from the exhaust manifold.

Diesel engine

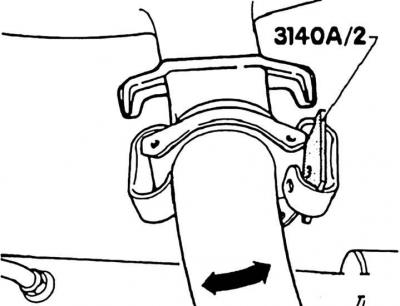

7. Press the exhaust pipe to the side so that the opposite spring plate is stretched. In this position, insert the short wedge VW-3140 A/2 or HAZET 2586 N-2 as far as it will go. Also stretch the second spring plate and insert the wedge.

8. Press the exhaust pipe forward towards the spring plate, which will be removed first. Check that the wedge is firmly seated in the spring plate and remove the plate.

9. Support the exhaust system at the front with a machine jack and release it from the circlips in the middle and at the rear.

10. Take out the exhaust system. 11. Exhaust system parts can also be removed piece by piece. If the connecting parts or bolts cannot be unscrewed, heat the exhaust pipe at the connection points with a gas burner.

Attention! Put asbestos in places of heating. Fire hazard!

Installation

Attention! Always replace rubber rings, nuts and bolts. To make it easy to remove the nuts and bolts of the exhaust system again, it is recommended to lubricate the threads with a heat-resistant paste, such as Liqui Moly LM-508-ASC, before installation.

1. Connect the front exhaust pipe and the additional muffler or catalytic converter together and slightly tighten the clamps without tightening. If required, before connecting, clean the connecting parts of the clamp with sandpaper from combustion products.

2. Replace the slip ring between exhaust manifold and front exhaust pipe only if damaged or leaking. If necessary, use a screwdriver to remove.

3. Install the stretched spring plates and make sure that they catch the tips in the recesses on the exhaust manifold, then press the front exhaust pipe aside.

Gas engine

4. Screw on the front exhaust pipe.

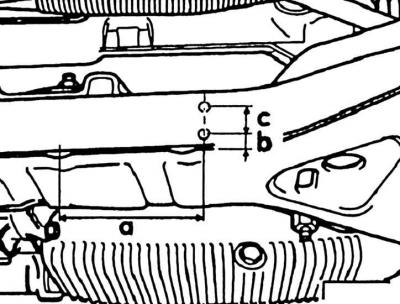

Attention! Since 6/92, a modified front exhaust pipe has been installed. Instead of suspension on the bottom of the machine, a thrust shield is installed on the bracket of mounted units. A modified exhaust pipe is offered as a spare part. If the front exhaust pipe is replaced on older machines, an additional stop plate must be installed. To do this, two 11 mm holes are drilled in the bracket of mounted units for blind rivets with nuts for fastening the thrust shield to the bracket. Dimensions (a = 120 mm from the middle of the middle groove, b = 24 mm from the lower edge of the attachment bracket, c = 30 mm hole spacing). The holes are then primed with a corrosion protection agent and the plate is screwed on with a torque of 20 Nm.

5. Install the exhaust silencer, do not tighten the clamps.

6. Before tightening the bolts, straighten the exhaust system, paying attention to a sufficient distance from the body (not less than 25 mm), if necessary, rotate or move the system in the longitudinal direction. Retaining rings must be loaded evenly. Make sure that the pipe is inserted deep enough into the clamps. Pay attention to the installation dimensions.

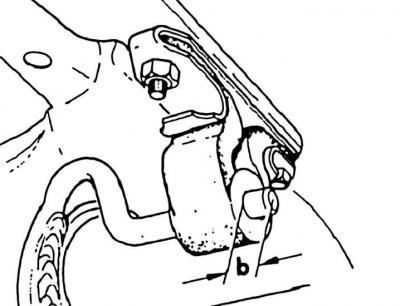

7. Pay attention to the fact that the ends of the hangers protrude from the rubber brackets according to the size "b". Then tighten the bolts and nuts. The tightening torques correspond to the thread diameters.

8. Install the lower engine compartment mudguard.

9. Take the car off the stands.

Visitor comments