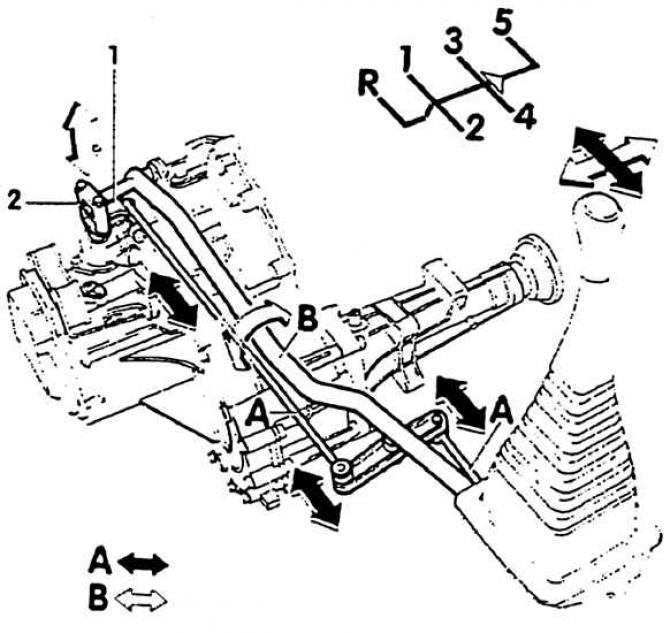

Gearbox drive

1. Gear shift lever; 2. Forked gear selection head; A. Shift rods; Arrow A. Switching movement; Arrow B. Selection movement

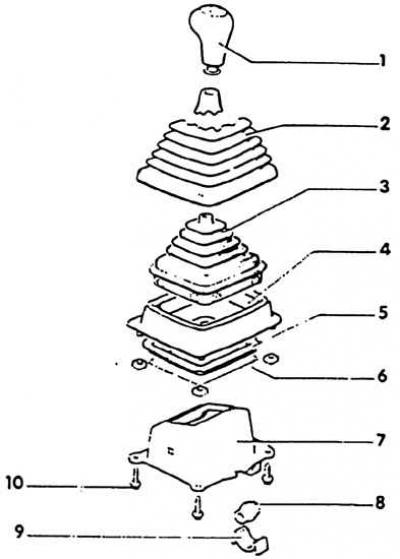

Switch housing

1. Switch knob - press into the bellows (2); 2. Corrugated cover - inserted into the frame (4); 3. Cuff - not available in all machines. Mounted with frame (4). Inscription "vorn" (forward) indicates the direction of movement.; 4. Frame - fit on the switch housing (7) and mounting screw. Inscription "vorn" (forward) indicates the direction of movement; 5. Gasket - installed between the frame and the bottom. Marking like an arrow points in the direction of movement; 6. Bottom; 7. Switch housing; 8. Support sleeve with switch bracket; 9. Bushing insert - when removing, squeeze both jumpers; 10. Screw, 9 Nm

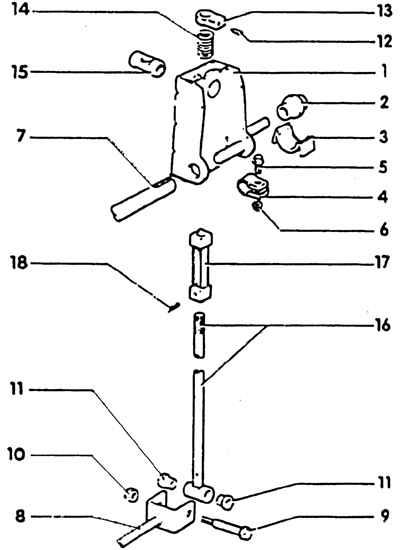

Shift lever

1. Shift bracket - remove with shift lever (16), after removing details (8, 7, 3) from shift lever or shift bracket; 2. Support sleeve; 3. bushing insert; 4. Tubular clamp - loosen to adjust the shift actuator and remove the shift bracket and selector rod; 5. Fixing screw; 6. Nut, 18 Nm; 7. Pull of choice; 8. Rear shift rod 9. Guide screw; 10. Nut, 5 Nm - self-tightening, therefore always replace; 11. Support sleeve; 12. Threaded pin; 13. Emphasis; 14. Pressure spring; 15. Support pin; 16. Shift lever - machines with separate seats: the shift lever at the rear is sloped backwards. Cars with a common seat: the shift lever back is not beveled.; 17. Guide sleeve; 18. Locking pin - knock out with a spike

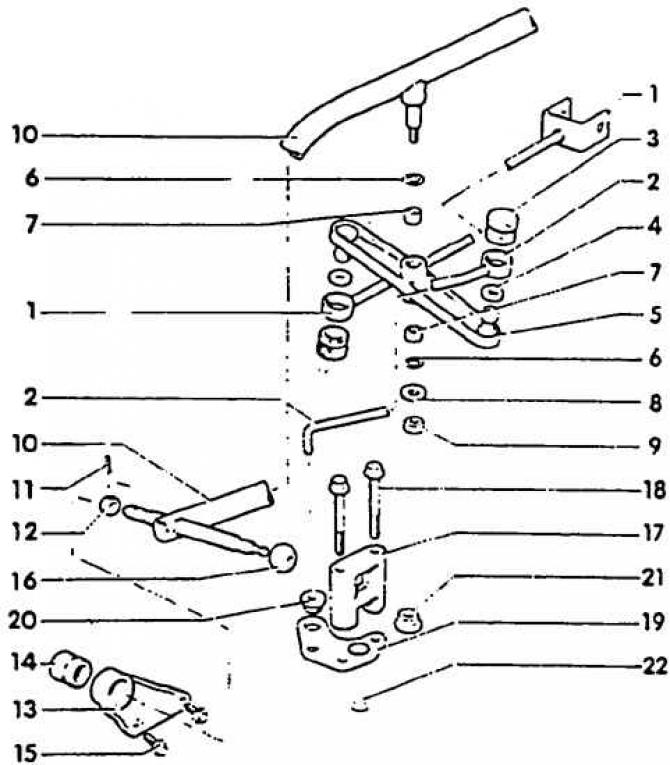

Shift rods and select rods

1. Rear shift rod; 2. Front shift rod; 3. Sleeve; 4 Sealing washer; 5. Bypass lever; 6. Round ring; 7. Support sleeve; 8. Washer; 9. Fastening nut, 25 Nm; 10. Pull of choice (remove from the gearbox together with the bearing bracket 13); 11. Locking sleeve; 12. Ball joint; 13. Bearing bracket; 14. Sleeve; 15. Screws for fastening the bearing bracket-gearbox, 20 Nm; 16. Choice rod ball joint in fork head; 17. Forked head; 18. Screw, 9 Nm; 19. Gearshift lever. Installed in only one position; 20. The basic plug of forward draft of switching; 21. Nut, 25 Nm; 22. Gearshift roller

Adjustment

1. Place transmission in neutral position, apply handbrake.

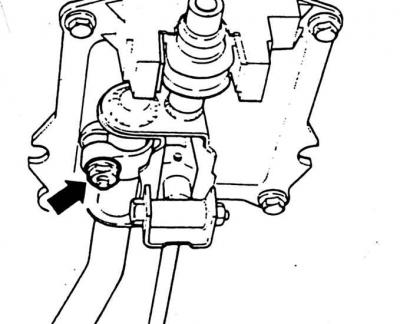

2. Loosen the clamp (arrow). The selection rod-switch arm connection must be easily movable.

3. Remove shift knob and bellows.

4. Remove the frame with cuff.

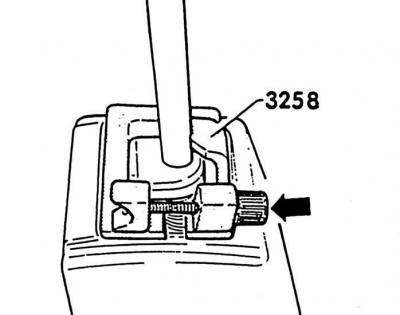

Attention! The contact surfaces of the stop and the switch housing must be parallel to each other. If necessary, align the stop before installing with the VW-3258 template.

5. Install the template until it stops and tighten with a screw (arrow).

6. Align the selection rod without tension - shift bracket (box in neutral) and tighten the clamping collar to 20 Nm.

7. Pull the shift lever towards the rear seat, loosen the screw and remove the template.

Gap check

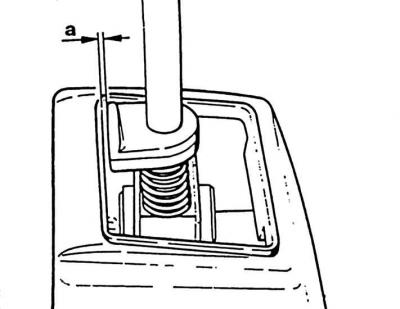

A. Gap

Checking work

1. The shift lever should be in the neutral position opposite 3-4 gears.

2. The bottom of the shift lever, below the bend, must be vertical.

3. Depress the clutch, start the engine, wait about 3-6 seconds for the gearbox drive shaft to stop, then repeatedly engage all gears. At the same time, pay attention to the operation of the reverse gear lock.

4. Install the frame with the cuff and the shift handle with the bellows.

5. If switching when switching on any gear still bites, turn on 1 gear.

6. Remove the gap in the shift drive, for which the shift lever with 1st gear engaged with a force of 2–3 N is pressed to the left by the thread of the shift handle. Gap (distance shift lever stop - shift housing stop) in this position should be: a = 1.3–2.3 mm.

7. Otherwise, turn off 1st gear and repeat the drive adjustment.

8. The hallmarks of a correct shift adjustment are: the perfect operation and interaction of the shift actuator components and the smooth running of the shift actuator.

Visitor comments